A semiconductor device testing device and testing method thereof

A test device and semiconductor technology, applied in the direction of single semiconductor device testing, etc., can solve problems such as affecting test results, ignition, etc., and achieve the effects of accurate test results, simple operation, and little external interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

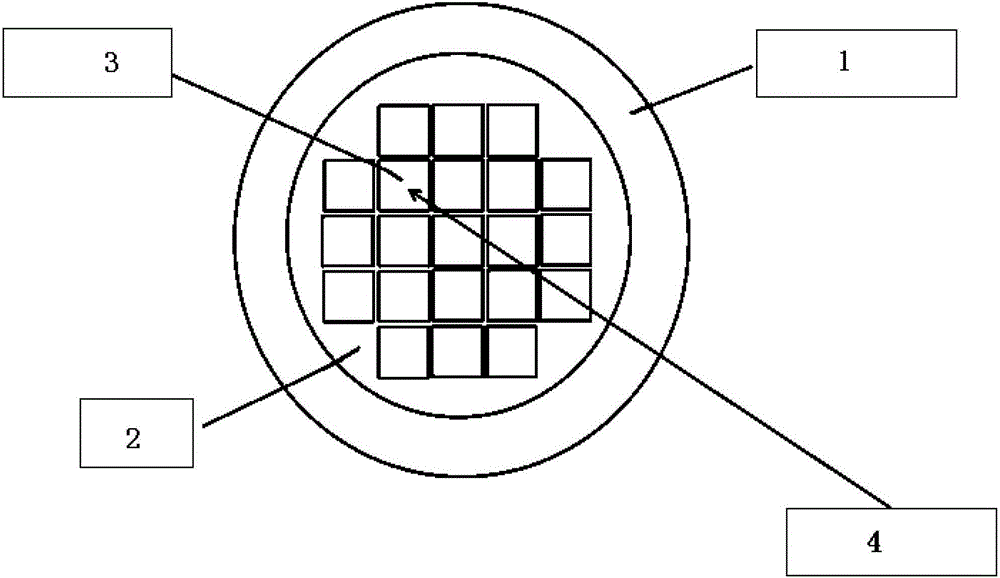

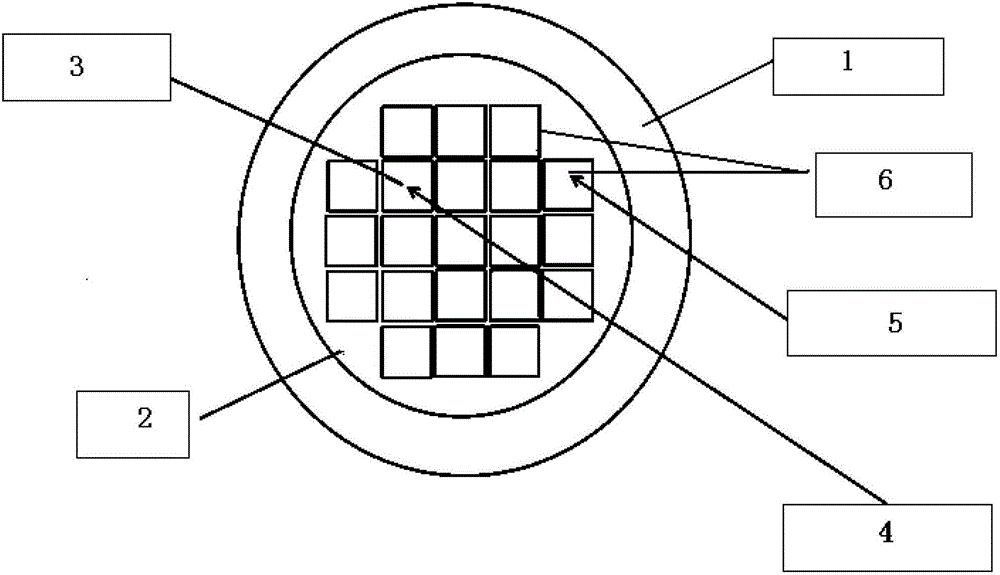

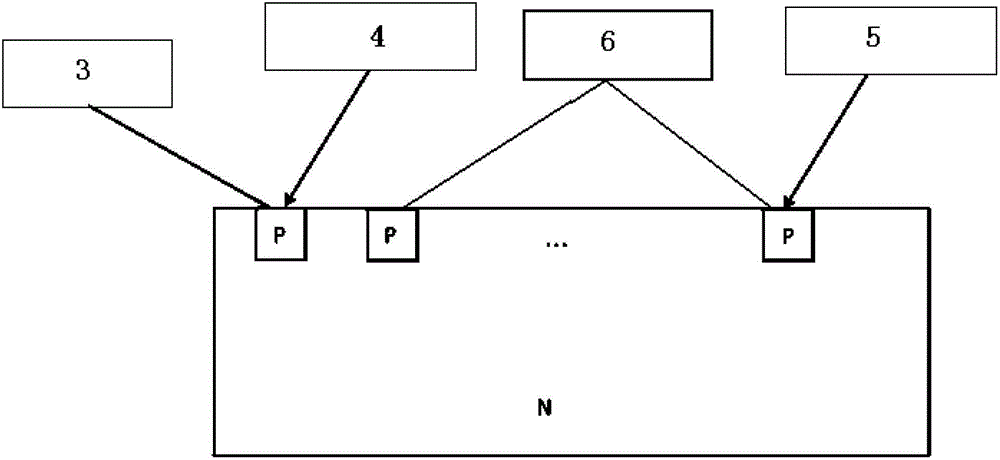

[0039] image 3 It is a test example 1 of the withstand voltage parameter Vbr of the high-voltage fast recovery diode (FRD) of the present invention. The high voltage probe is in contact with any non-test chip, image 3 Shown are the cross-sectional views of the test probe and the high-voltage probe and the chip respectively. Depend on image 3 It can be seen that the wafer is fixed on the table, and the test chip 3 and the non-test chip 6 are selected. The test chip 3 is in contact with the test probe 4, and the potential is grounded. The non-test chip 6 is in contact with the high voltage probe 5 . image 3 In the test example, the high voltage probe 5 applies high voltage, and the test chip 3 is grounded. Test the reverse voltage of the chip 3, that is, the reverse voltage of the P / N junction. In Test Example 1, only the P / N junction forward voltage of 0.7V is introduced. For 1200V or higher voltage devices, the test error is very small, and the test accuracy can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com