Graphene/metal composite negative electrode material for lithium ion battery and preparation method of graphene/metal composite negative electrode material

A technology for lithium-ion batteries and negative electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of easy stacking, verticality, and difficulty in collecting fluids of negative electrode materials, so as to simplify the production process, reduce production costs, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Under ice bath conditions, 3.0g of graphite was added to 60ml of concentrated sulfuric acid, stirred vigorously for 30min, and further 12gKMnO 4 Add to the above mixture and stir vigorously for 30min. Transfer the above mixture to a 30°C water bath, slowly add 18g NaNO 3 , stirred for 60min; while stirring, continuously added 140ml of deionized water to the above mixture, then transferred it to an oil bath at a temperature of 90°C, stirred for 30min; then added 18ml of H 2 o 2 , continue to react for 60min to make the solution change from dark brown to bright yellow;

[0032] Under stirring conditions, add 1.5wt% dispersing agent PAA of graphene oxide to the above graphene oxide solution, dissolve and add 20ml of hydrazine hydrate solution dropwise, react at 60°C for 1h, and further dissolve in the above solution 20ml of 20wt% acetic acid aqueous solution was added dropwise, and the reaction was continued for 30min to obtain a stable graphene aqueous solution.

[00...

Embodiment 2

[0037] Under ice bath conditions, 3.0g of graphite was added to 60ml of concentrated sulfuric acid, stirred vigorously for 30min, and further 12gKMnO 4 Add to the above mixture and stir vigorously for 30min. Transfer the above mixture to a 30°C water bath, slowly add 18g NaNO 3 , stirred for 60min; while stirring, continuously added 140ml of deionized water to the above mixture, then transferred it to an oil bath at a temperature of 90°C, stirred for 30min; then added 18ml of H 2 o 2 , continue to react for 60min to make the solution change from dark brown to bright yellow;

[0038] Under stirring conditions, add 2.5wt% dispersing agent PAA of graphene oxide to the above graphene oxide solution, dissolve and add 20ml of hydrazine hydrate solution dropwise, react at 80°C for 1h, and further dissolve in the above solution 20ml of 10wt% acetic acid aqueous solution was added dropwise, and the reaction was continued for 40min to obtain a stable graphene aqueous solution.

[00...

Embodiment 3

[0043] Under ice bath conditions, 3.0g of graphite was added to 60ml of concentrated sulfuric acid, stirred vigorously for 30min, and further 12gKMnO 4 Add to the above mixture and stir vigorously for 30min. Transfer the above mixture to a 30°C water bath, slowly add 18g NaNO 3 , stirred for 60min; while stirring, continuously added 140ml of deionized water to the above mixture, then transferred it to an oil bath at a temperature of 90°C, stirred for 30min; then added 18ml of H 2 o 2 , continue to react for 60min to make the solution change from dark brown to bright yellow;

[0044] Under stirring conditions, add 2.5wt% dispersing agent PAA of graphene oxide to the above graphene oxide solution, dissolve and add 20ml of hydrazine hydrate solution dropwise, react at 80°C for 1h, and further dissolve in the above solution 20ml15wt% acetic acid aqueous solution was added dropwise, and the reaction was continued for 50min to obtain a stable graphene aqueous solution.

[0045] ...

PUM

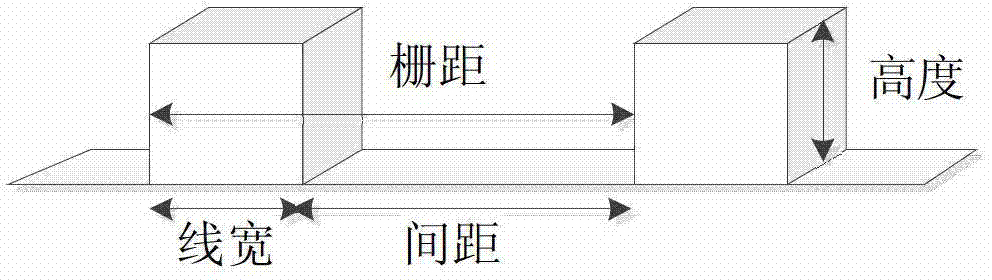

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com