Insulated gate bipolar transistor gate driving push-pull circuit

A technology of bipolar transistors and push-pull circuits, which is applied in the field of gate drive push-pull circuits of insulated gate bipolar transistors, and can solve the problems of large turn-on voltage drop of MOS transistors, poor reliability of push-pull circuits, and poor ability to suppress IGBT short-circuit current, etc. problem, to achieve the effect of small drive circuit loss, improve work reliability, and improve overall reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

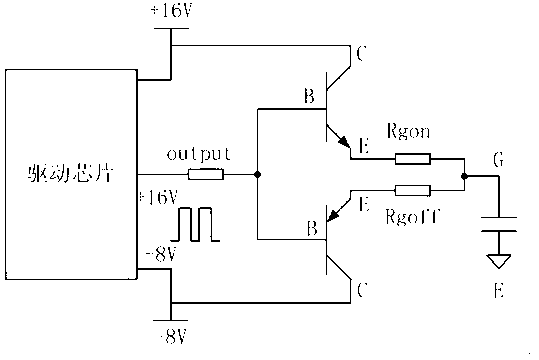

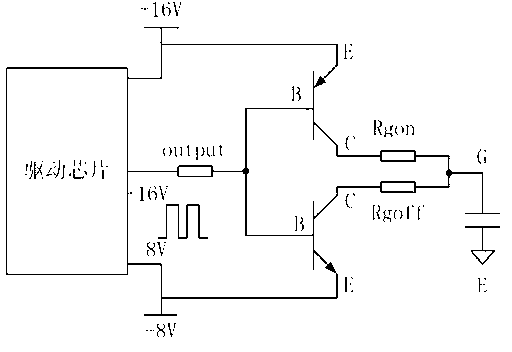

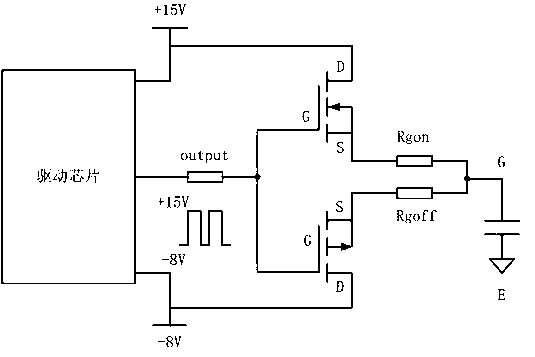

[0056] Figure 5 It is a schematic diagram of the structure of the IGBT drive push-pull circuit with effective gate clamping and negative voltage shutdown of the present invention, which is composed of a drive chip, an IGBT gate drive resistor, and a gate drive push-pull circuit. The gate drive push-pull circuit is composed of a front-stage push-pull circuit, a level conversion circuit, and a rear-stage push-pull circuit. The front-stage push-pull circuit, the level conversion circuit and the rear-stage push-pull circuit share the positive and negative power supplies of the secondary side of the drive chip. The output of the driver chip is connected to the front-stage push-pull circuit, the output of the front-stage push-pull circuit is connected to the level conversion circuit, the output of the level conversion circuit is connected to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com