Gas-liquid separating device of low-temperature methanol washing absorption tower

A gas-liquid separation device, low-temperature methanol washing technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as methanol carry-out, and achieve the effects of reducing waste, ensuring safety, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment.

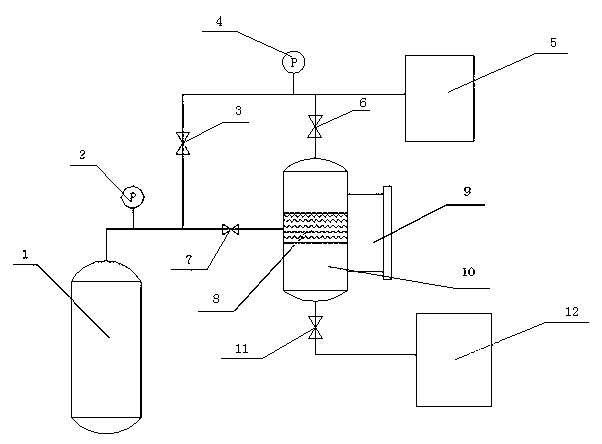

[0017] Such as figure 1 Shown structure schematic diagram of the present invention comprises absorption tower 1 and gas-liquid separator 10, is provided with demister 8 in gas-liquid separator 10, and absorption tower 1 links to each other with demister 8 in gas-liquid separator 10 through pipeline, The demister 8 can intercept and remove liquid methanol. The pipeline is equipped with a pressure gauge a2 for detecting and indicating the system pressure and a valve c7 for controlling the operation and stop of the equipment. The absorption tower 1 and the gas-liquid separator 10 pass through the valve a3 and the valve b6 respectively. Connected to the liquid nitrogen washing unit 5, a pressure gauge b4 is provided on the pipeline, the lower end of the gas-liquid separator 10 is connected to the low-temperature solution system 12, and a valve d11 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com