Method for controlling reverse penetration into back of aluminium alloy pipeline during welding

A technology for aluminum alloy pipes and pipelines, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of poor welding seam back forming, difficulty in using rigid mandrels for continuous bends, and increase production costs. The amount of reverse penetration on the back of the weld, good welding seam forming quality, and the effect of being beneficial to the welding seam forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

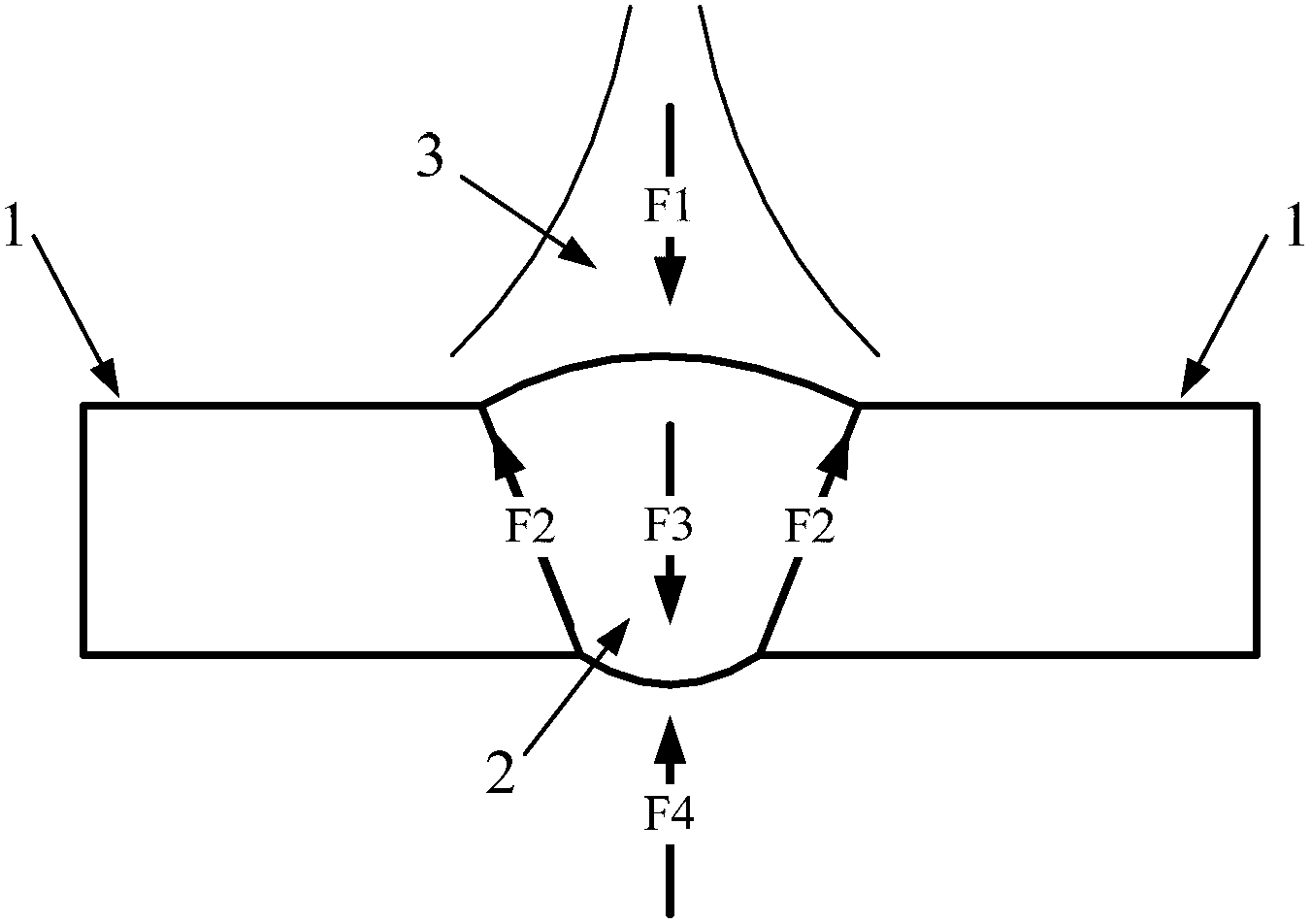

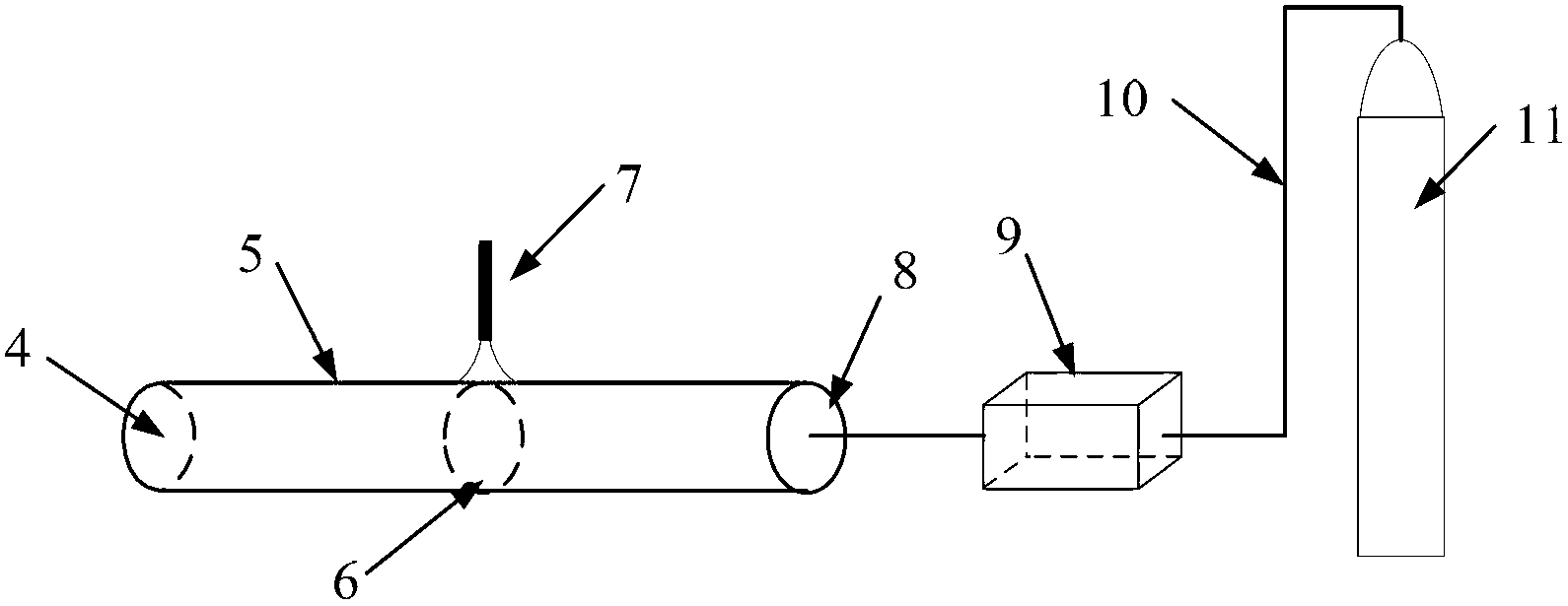

[0029] Example 1: Butt argon arc welding of 5A06 aluminum alloy pipeline

[0030] Base material: 5A06 aluminum alloy pipe with outer diameter of 38mm and wall thickness of 1.5mm, butt argon arc welding. The whole welding process is divided into two stages: the point-fixed air-filling stage and the welding pressure-regulating stage. After the pipeline is properly assembled and tapped, both ends of the pipeline are blocked. Start to fill the pipeline with argon at a flow rate of 12L / min. After inflating for 1-2 minutes, the welding will be carried out. The welding current is 50A. Gradually reduce the inflation flow to ensure the dynamic stability of the internal air pressure. The finally obtained pipeline welds are uniform and beautiful, without defects such as incomplete penetration and lack of fusion, and the back of the weld has a proper amount of reflection, which can meet the requirements of QJ919A-1998 for Φ32mm steel balls.

Embodiment 2

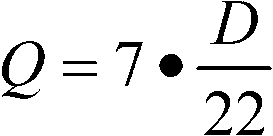

[0031] Example 2: Butt argon arc welding of 5A03 aluminum alloy pipeline

[0032] Base material: 5A03 aluminum alloy pipe with outer diameter of 22mm and wall thickness of 1.0mm, butt argon arc welding. The whole welding process is divided into two stages: the point-fixed air-filling stage and the welding pressure-regulating stage. After the pipeline is properly assembled and tapped, both ends of the pipeline are blocked. Start to fill the pipeline with argon. The flow of argon is 7L / min. After inflating for 1-2 minutes, the welding is carried out. The welding current is 40A. Gradually reduce the inflation flow to ensure the dynamic stability of the internal air pressure. The finally obtained pipeline welds are uniform and beautiful, without defects such as incomplete penetration or lack of fusion, and the back of the weld has a proper amount of reflection, which can meet the requirements of QJ919A-1998 for Φ17mm steel balls.

Embodiment 3

[0033] Example 3: Butt argon arc welding of 5A02 aluminum alloy pipeline

[0034] Base material: 5A02 aluminum alloy pipe with outer diameter of 40mm and wall thickness of 3.0mm, butt argon arc welding. The whole welding process is divided into two stages: the point-fixed air-filling stage and the welding pressure-regulating stage. After the pipeline is properly assembled and tapped, both ends of the pipeline are blocked. Start to fill the pipeline with argon. The flow of argon is 12.7L / min. After inflating for 1-2 minutes, the welding current is 55A. Gradually reduce the inflation flow to ensure the dynamic stability of the internal air pressure. The finally obtained pipeline weld is uniform and beautiful, without defects such as incomplete penetration and lack of fusion, and the amount of back reflection of the weld is appropriate, which can meet the requirements of QJ919A-1998 for Φ30mm steel balls.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com