Marking machine and automatic marking system

A technology of marking machine and frame, applied in the field of marking machine and automatic marking system, can solve the problems of operator's health injury, reduced production efficiency, inclined marking characters, etc., so as to improve production efficiency and avoid job change. cost, the effect of reducing quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

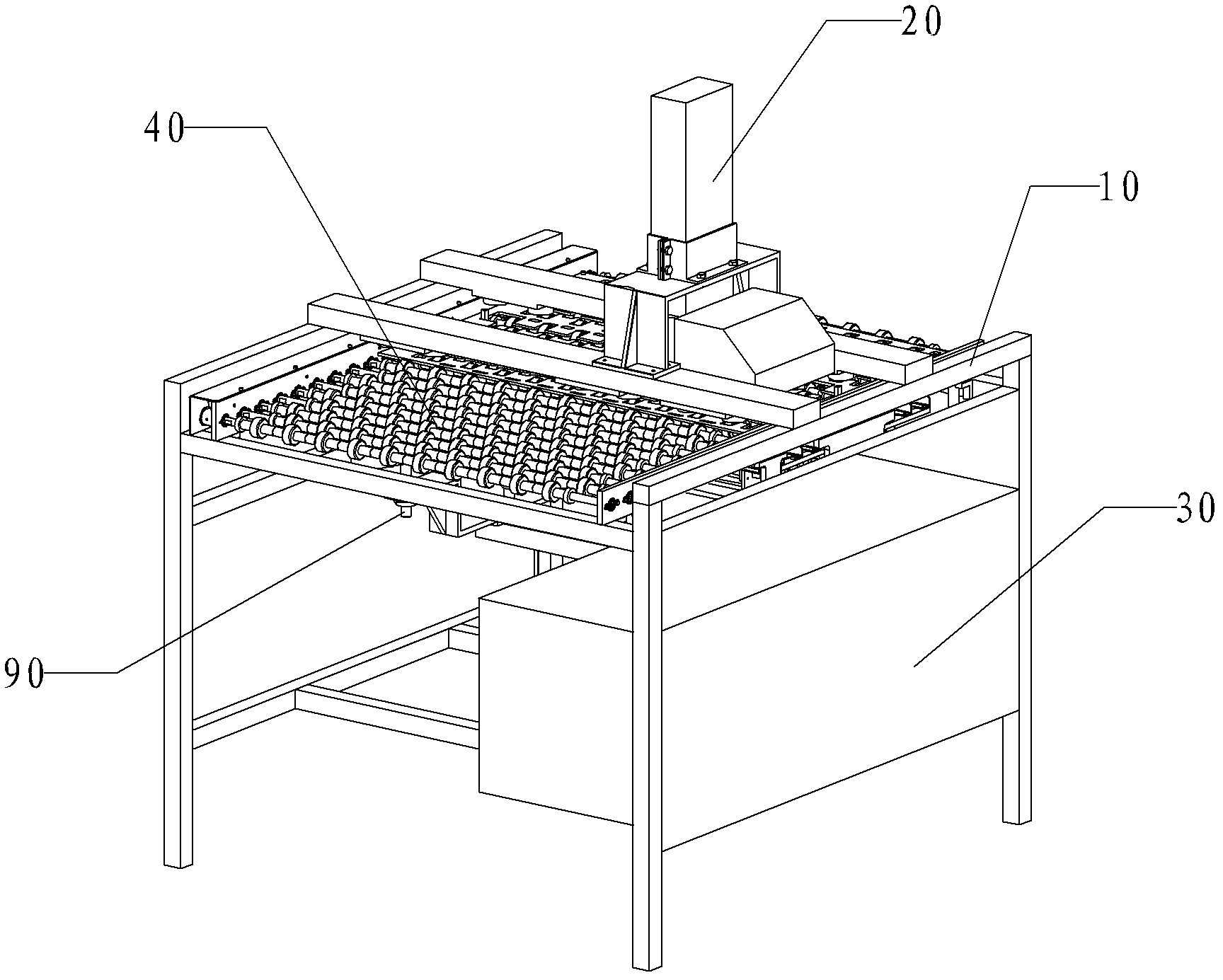

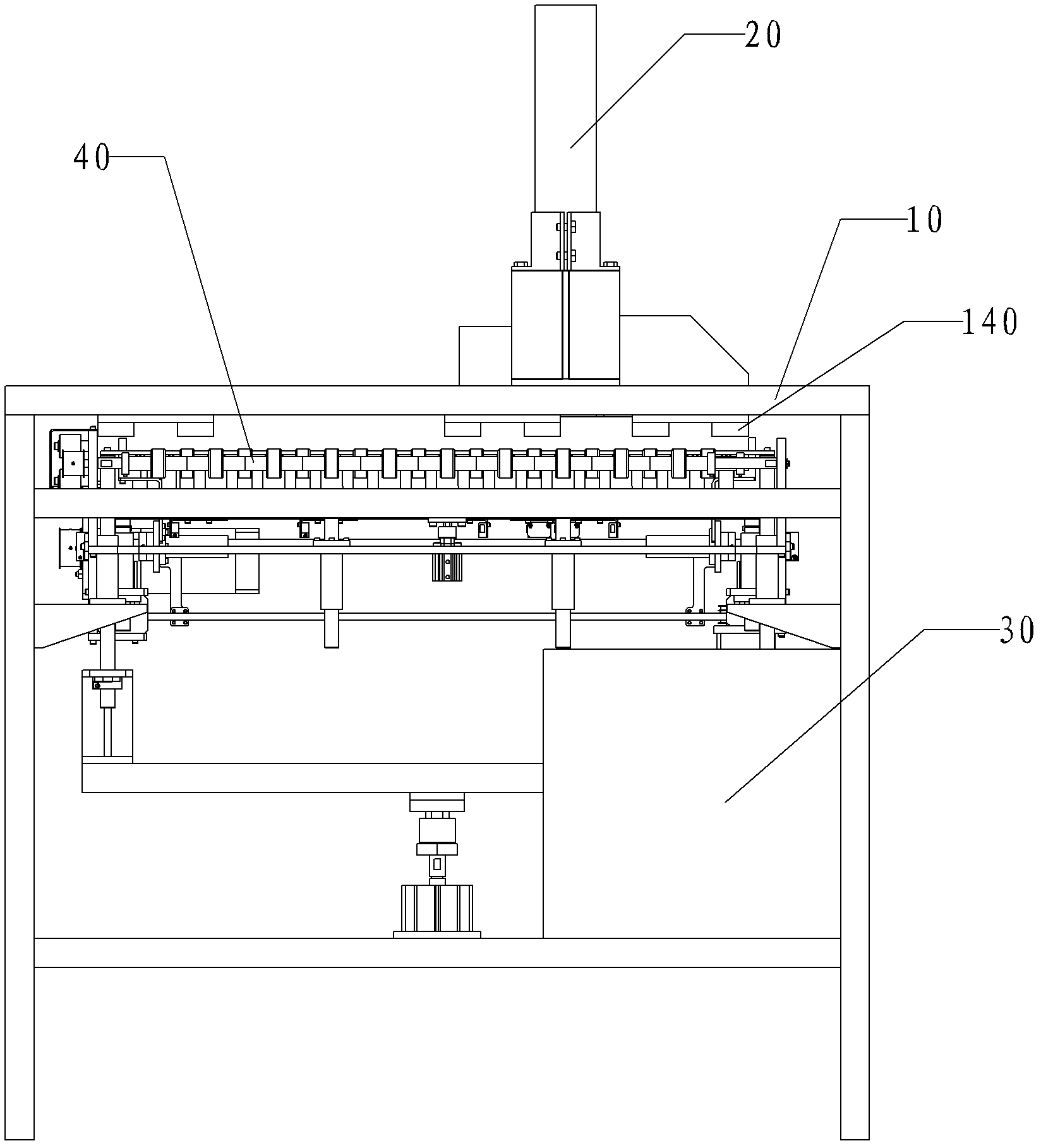

[0033] Reference Figure 1 to Figure 5 As shown, the marking machine of the present invention includes a frame 10 and a marking device 20 installed on the frame 10, an electrical control device 30, a transmission device, an adjustment device, a sensing device and a pressing device.

[0034] The marking device 20 includes a driving mechanism and a drill bit 203. The driving mechanism includes a control device 201 and a lifting cylinder 202. The control device 201 is electrically connected to the lifting cylinder 202, the computer 204, and the electrical control device 30, respectively. The piston rod of the lifting cylinder 202 is connected with the drill bit 203.

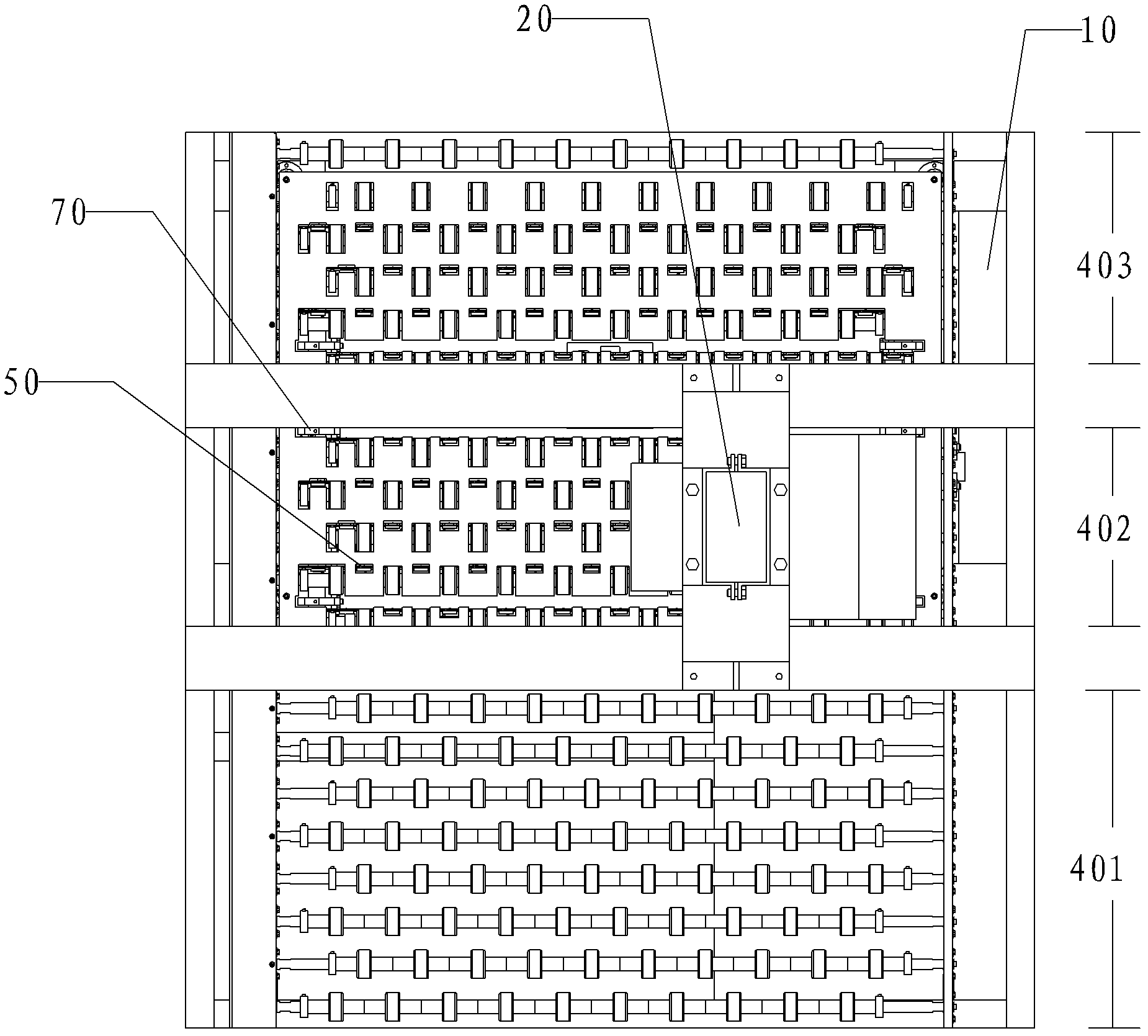

[0035] Reference image 3 As shown, the conveying device includes a driving motor and a conveying race 40, and the driving motor controls the operation of the conveying race 40. The conveying race 40 includes a feeding area 401, a working area 402, and an output area along the conveying direction. Material area 403, the...

Embodiment 2

[0054] Reference Image 6 As shown, the automatic marking system of the present invention includes an upstream assembly line 1000, a marking machine, and a downstream assembly line 3000. The marking machine is the marking machine in the above-mentioned embodiment, and the conveyor roller 40 of the marking machine The feed zone 401 is connected to the output end of the upstream assembly line 1000, and the discharge zone 403 of the conveying roller 40 of the marking machine is connected to the input end of the downstream assembly line 3000.

[0055] Using the automatic marking system of the present invention can realize automatic marking production without causing harm to the health of the operators, improving the working environment of the employees, and reducing the quality problems caused by human factors in the marking process. ; Since there is no need to change jobs, the cost of changing jobs is avoided and production efficiency is improved. The automatic marking system of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com