Front cabin steel-frame structure of electric vehicle and front cabin

An electric vehicle and front cabin technology, applied in the front cabin field, can solve the problems of weak strength and reduce vehicle collision energy absorption space, and achieve the effects of low manufacturing cost, improved safety performance, and increased energy absorption space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

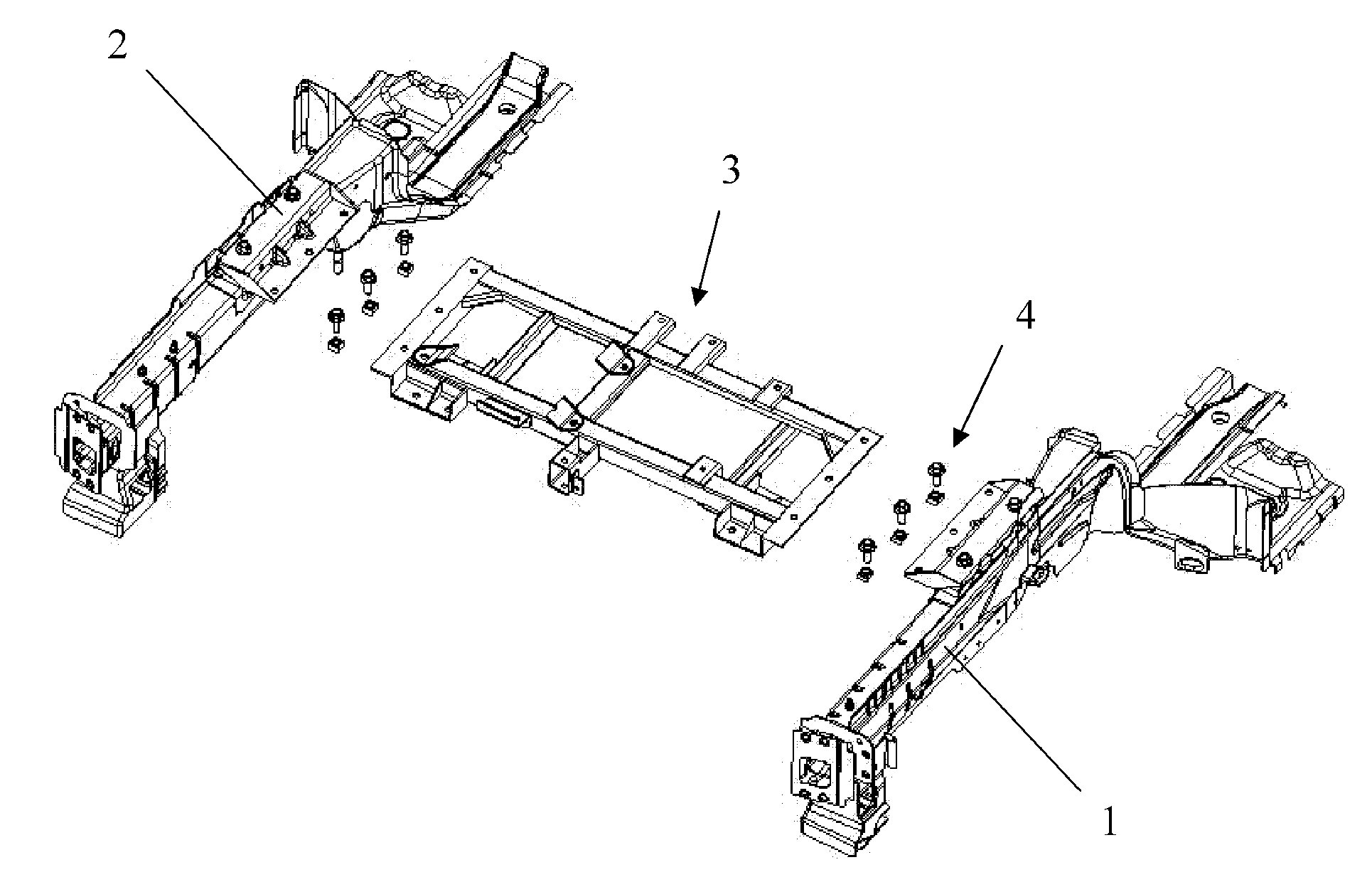

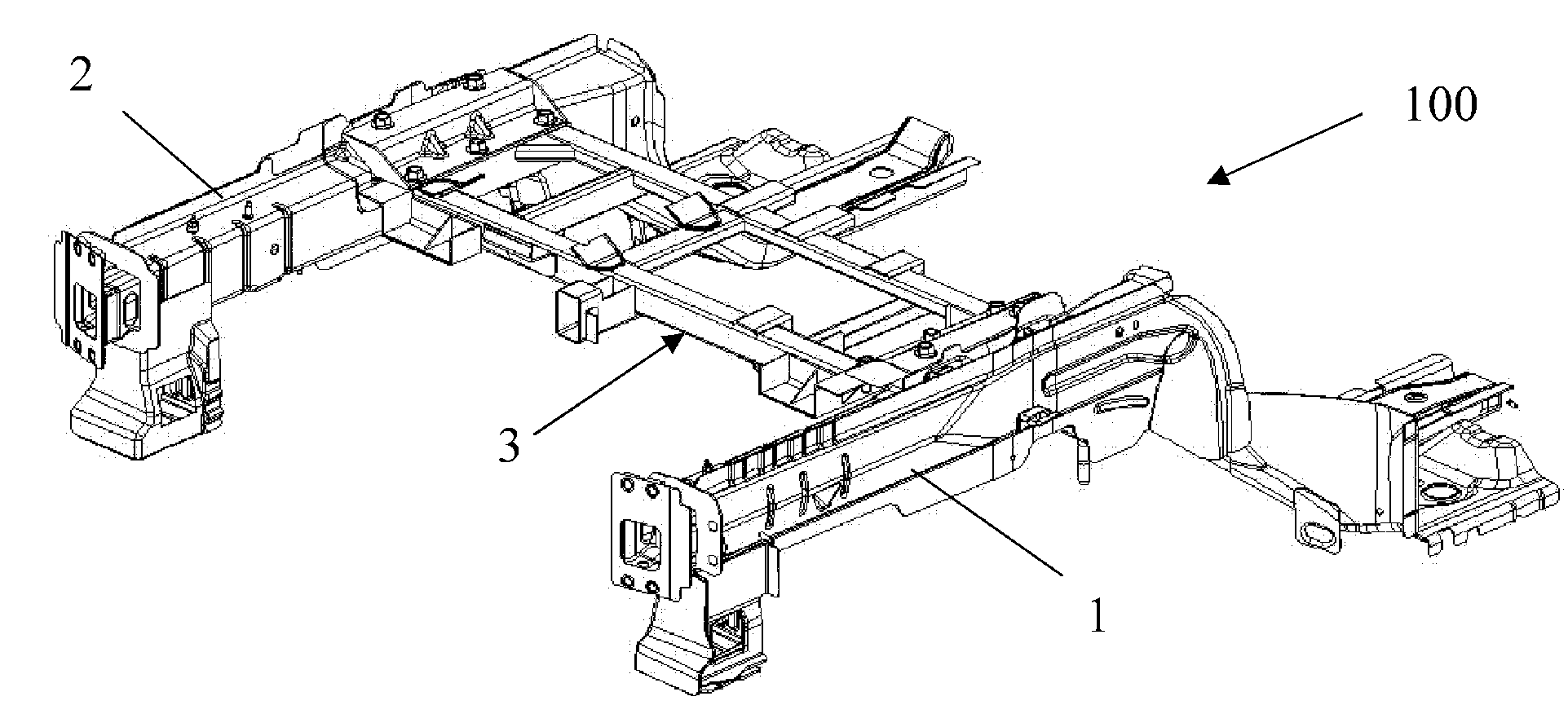

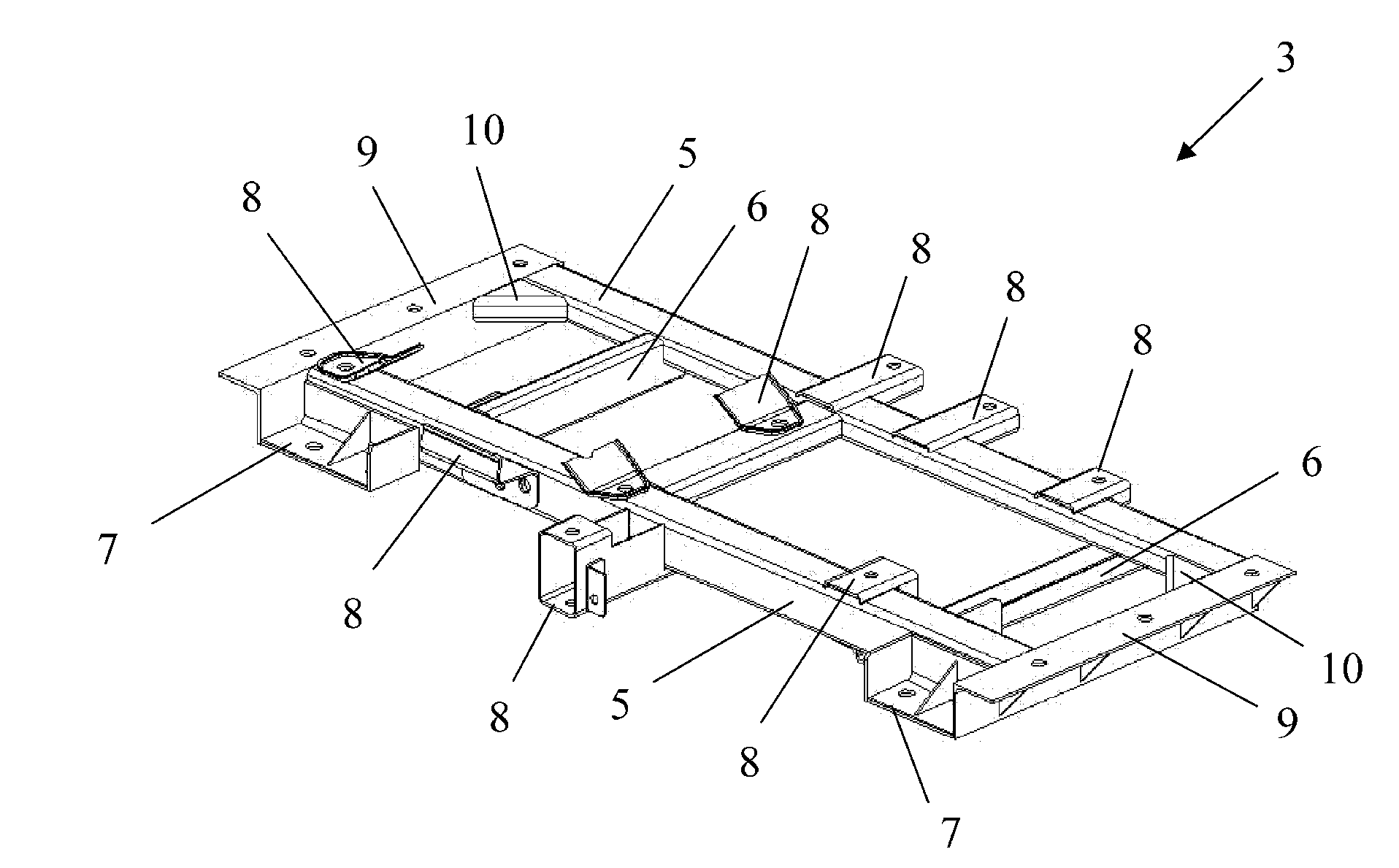

[0033] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] It is easy to understand that, according to the technical solution of the present invention, those skilled in the art can propose multiple structural modes and implementation modes that can be replaced without changing the essence and spirit of the present invention. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solution of the present invention, and should not be regarded as the entirety of the present invention or as a limitation or restriction on the technical solution of the present invention.

[0035] The orientation terms such as up, down, front, and back mentioned in this specification are defined relative to the elements shown in the drawings. They are relative concepts, so they may vary according to their different positions, Change accordingly for different usage co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com