Quick repairing glue for surface defects of natural rubber soles and preparation method of quick repairing glue

A natural rubber and repair rubber technology, applied in the rubber field, can solve the problems of lack of rubber on the surface, air bubbles, etc., and achieve the effect of fast vulcanization speed, high vulcanization degree, and early vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1 A kind of natural rubber sole surface defect rapid repair glue and preparation method thereof

[0061] The preparation method of the above-mentioned natural rubber sole surface defect fast repair glue, it carries out according to the following steps:

[0062] (1) Mastication of natural rubber

[0063] Put the natural rubber into the 450-type open mill for mastication, adjust the distance between the rollers of the open mill to 1.5mm-2mm, pass the natural rubber six to seven times, and test the plasticity of the natural rubber. The plasticity is required to be 0.55-0.60, if it does not meet the requirements, continue to thin it until it is qualified. In this way, natural rubber that meets the requirements of mastication is obtained;

[0064] (2) Preparation of raw materials

[0065] Accurately weigh the masticated natural rubber and other required raw materials according to the table below, and set aside;

[0066] material name Weight (kg) ...

Embodiment 2-7

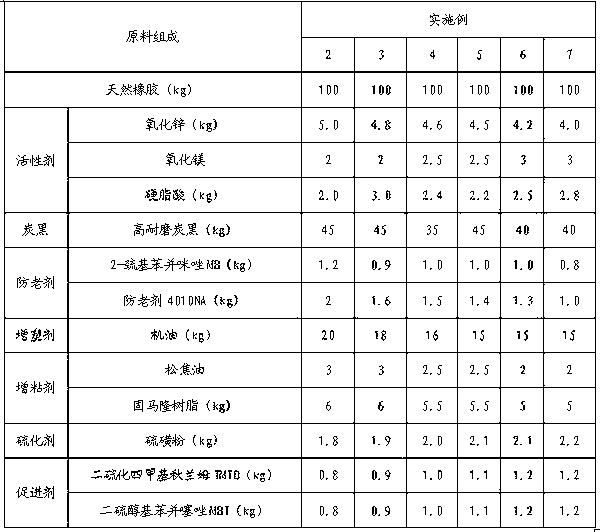

[0079] The difference between embodiment 2-7 and embodiment 1 is only the difference in the consumption of the raw material composition involved, and its preparation method is the same, and the specific difference is as shown in the following table:

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com