Aging machine

A curing machine and frame technology, applied in the field of curing machines, can solve the problems of large space for heat dissipation, difficulty in shaping paper, paper rolls from tight to loose, etc., and achieve the effects of reducing parking time, simple structure, and reducing defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

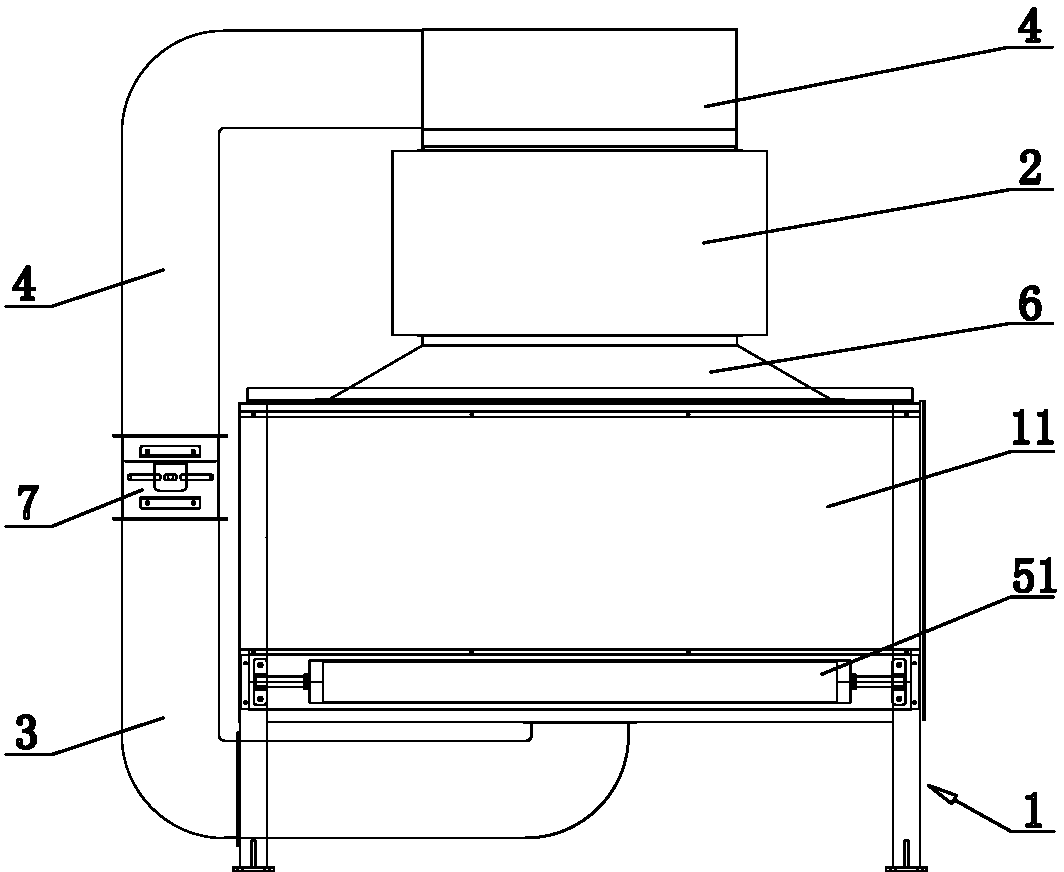

[0033] Figure 1~ figure 2 Shown, a kind of curing machine, it comprises frame 1, air conditioner 2, return air duct 3, air supply duct 4, described frame 1 is provided with cooling room 11, and described cooling room 11 is provided with air inlet and outlet The air outlet, the return air duct 3 is connected to the air outlet, the return air duct 3 is connected to the air supply duct 4, the air supply duct 4 is connected to the air conditioner 2, and the air conditioner 2 is connected to the air conditioner. The air inlet is connected; it also includes a paper-leading roller mechanism 5 , and the paper-leading roller mechanism 5 is arranged on the frame 1 . A bell mouth 6 is provided between the air conditioner 2 and the air inlet. The bell mouth 6 can make the cold air of the air conditioner 2 be evenly distributed in the cooling chamber 11, so that the middle and both sides of the paper can be evenly cooled.

[0034] A fan 7 is provided at the joint between the return air ...

Embodiment 2

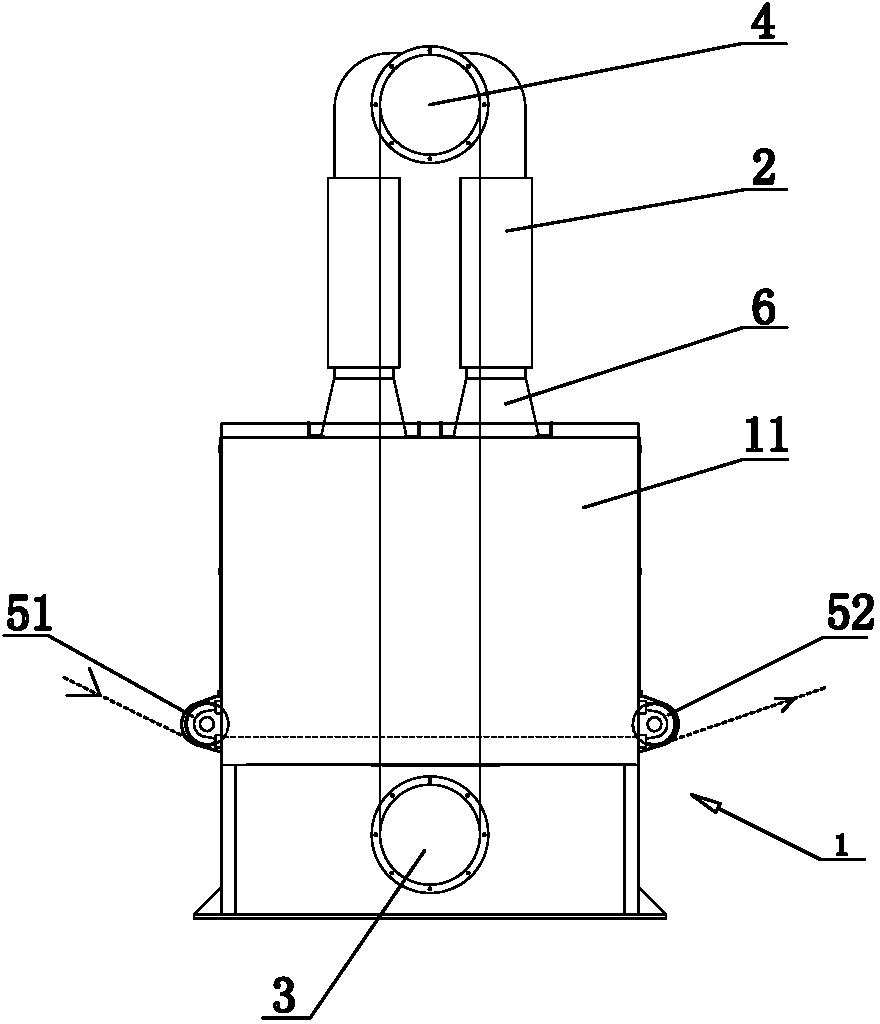

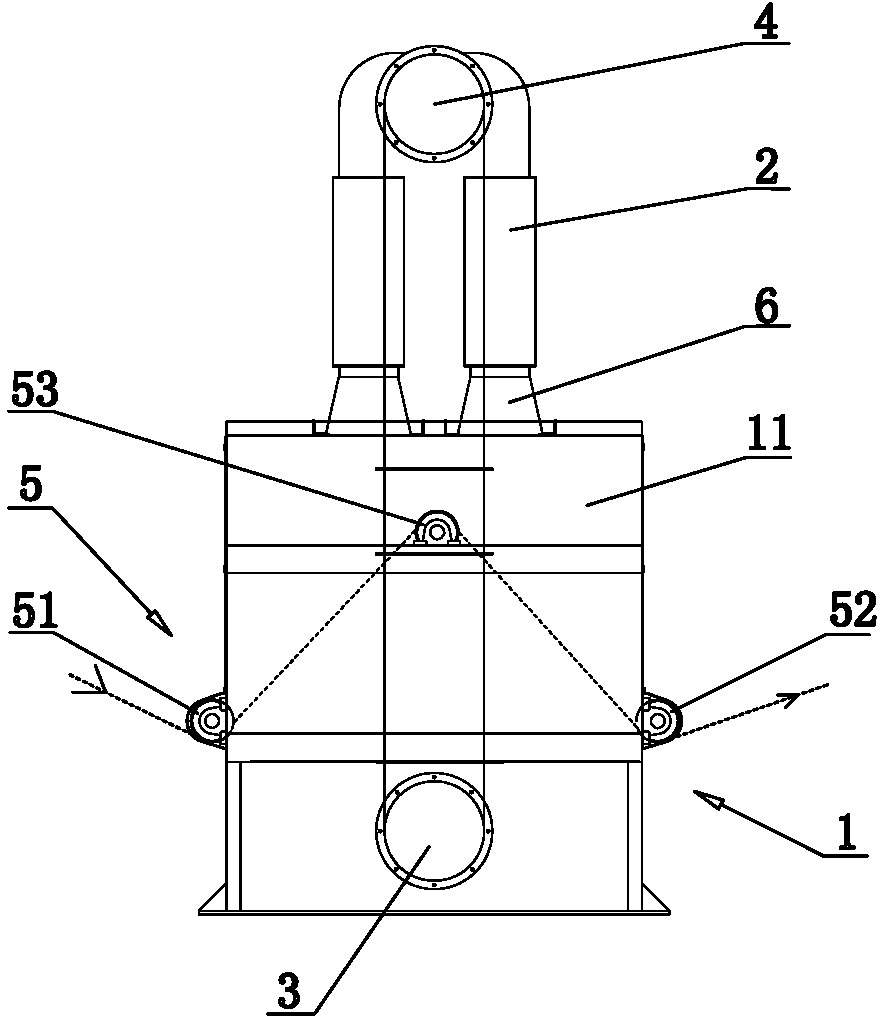

[0040] like image 3 As shown, the difference between this embodiment and Embodiment 1 is that: the threading roller mechanism 5 of this embodiment further includes an inner threading roller 53 , and the inner threading roller 53 is arranged in the cooling chamber 11 . The paper passes through the inner paper threading roller 53, and the inner paper threading roller 53 makes the paper go through a longer displacement in the cooling chamber 11, prolongs the residence time of the paper in the cooling chamber 11, and achieves a better cooling effect. The dotted lines and arrows in the figure represent the orientation of the paper.

[0041] Preferably, there are at least two inner paper threading rollers 53 , and the at least two inner paper threading rollers 53 are arranged in the cooling chamber 11 vertically and alternately. like Figure 4 As shown, there are three inner paper threading rollers 53, and the paper passes through the three inner paper threading rollers 53 arrang...

Embodiment 3

[0048] like Image 6 As shown, the difference between this embodiment and Embodiment 2 is that: the outer wall of the cooling chamber 11 in this embodiment is provided with an insulating layer 8 . The insulation layer 8 is made of insulation material, and the insulation layer 8 further ensures that the temperature in the cooling chamber 11 is constant, reduces the loss of cold air and improves the utilization rate of resources.

[0049] Features that are not explained in this embodiment are explained in Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com