Direct acting two-way inserting sheet type electromagnet

A plug-in electromagnet technology, applied to the static parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problems of coil heating, high weight, serious eddy current effect, etc., and achieve structural strength and rigidity Effects of lightening, improving power-to-weight ratio, and alleviating heat problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

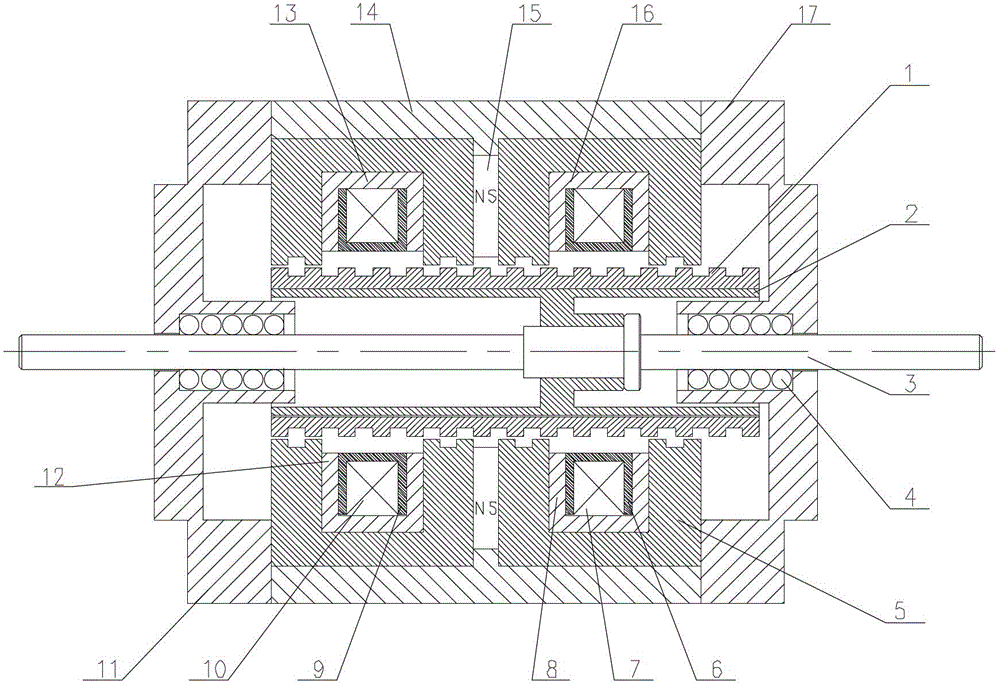

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

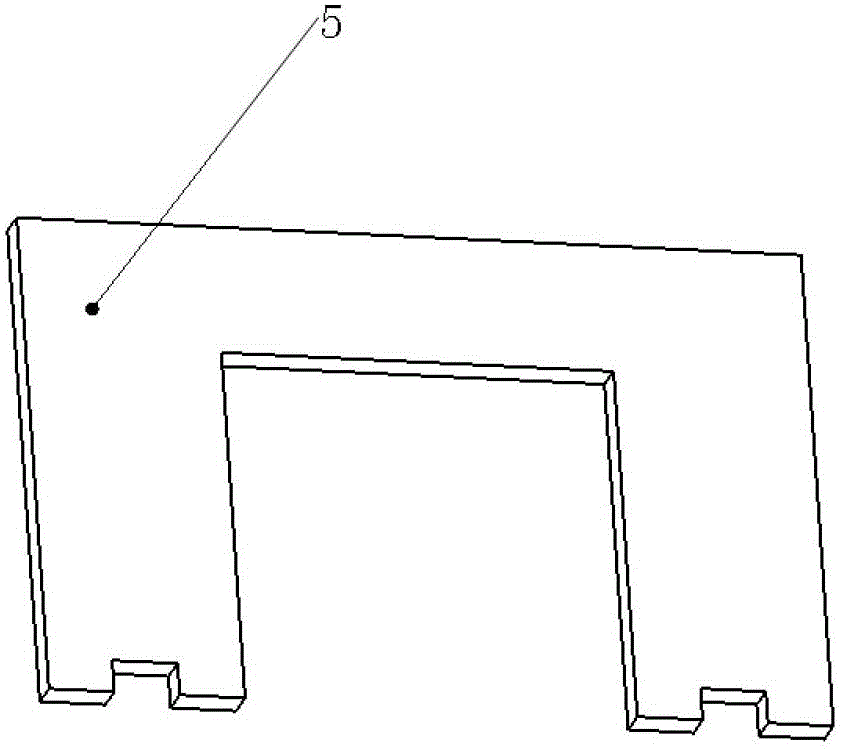

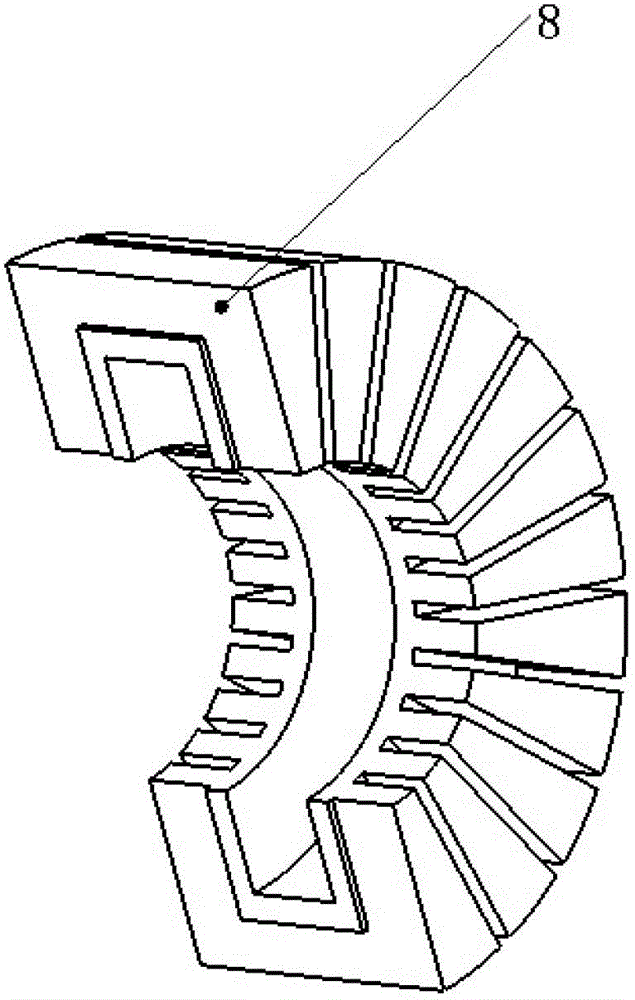

[0021] Such as figure 1 with Figure 7 As shown, the present invention includes a stator component, an armature component, a housing, and front and rear end covers. The stator part is located outside the armature part, and the stator part includes a first stator holder 12, a second stator holder 13, a third stator holder 8, a fourth stator holder 16, a stator silicon steel sheet 5, a second stator holder A coil holder 9 , a second coil holder 6 , a first control coil 10 , a second control coil 7 , a permanent magnet 15 and a housing 14 . The housing 14 is the matrix of the stator components, used to support and accommodate other stator parts; the first stator holder 12, the second stator holder 13, the third stator holder 8, the fourth stator holder 16 is injection molding of high-strength reinforced nylon material, which can greatly reduce the weight of the whole m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com