Method for producing feed microecological preparation by synergic fermentation of probiotics

A micro-ecological preparation and collaborative fermentation technology, which is applied in the fields of application, animal feed, animal feed, etc., can solve the problems of weak disease resistance, low feed conversion rate and production performance, and large toxic and side effects, so as to promote animal growth and improve animal health. Intestinal microenvironment, the effect of improving protein utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] With Bacillus subtilis, Lactobacillus plantarum and Candida as bacterial strains, Bacillus subtilis, Lactobacillus plantarum and Candida are all inserted into the fermenter according to the 5% inoculation amount of the medium volume and mixed evenly, and the medium is By weight: 96% chrysanthemum meal, 0.8% astragalus, 0.8% forsythia, 0.8% houttuynia, 0.8% hawthorn and 0.8% tangerine peel, mixed and evenly crushed through a 60-mesh sieve, first carried out aerobic ventilation fermentation, fermentation The temperature is 30°C, the ventilation rate is 0.5L / min, the ventilation is stopped for 10min every 30min, the stirring speed is 45r / min, cultivated for 28h, and then anaerobic fermentation is carried out, the fermentation temperature is 32°C, the stirring speed is 20r / min, and cultivated for 24h.

Embodiment 2

[0011] With Bacillus subtilis, Lactobacillus plantarum and Candida as bacterial strains, Bacillus subtilis, Lactobacillus plantarum and Candida are all inserted into the fermenter according to the 7.5% inoculation amount of the medium volume and mixed evenly, and the medium is By weight: 95% chrysanthemum meal, 1% astragalus, 1% forsythia, 1% houttuynia, 1% hawthorn and 1% tangerine peel, mixed and evenly crushed through an 80-mesh sieve, first aerobic ventilation fermentation, fermentation The temperature is 33°C, the ventilation rate is 0.8L / min, the ventilation is stopped for 10min every 30min, the stirring speed is 52r / min, cultivated for 34h, and then anaerobic fermentation is carried out, the fermentation temperature is 33°C, the stirring speed is 30r / min, and cultivated for 36h.

Embodiment 3

[0013] With Bacillus subtilis, Lactobacillus plantarum and Candida as bacterial strains, Bacillus subtilis, Lactobacillus plantarum and Candida are all inserted into the fermenter according to the 10% inoculation amount of the medium volume and mixed evenly, and the medium is By weight: 94% chrysanthemum meal, 1.2% astragalus, 1.2% forsythia, 1.2% Houttuynia cordata, 1.2% hawthorn and 1.2% tangerine peel, mixed evenly and crushed through a 100-mesh sieve, first carried out aerobic ventilation fermentation, fermentation The temperature is 35°C, the ventilation rate is 1.2L / min, the ventilation is 30min, stop for 10min, the stirring speed is 60r / min, cultivate for 40h, and then carry out anaerobic fermentation, the fermentation temperature is 35°C, the stirring speed is 40r / min, and cultivate for 48h.

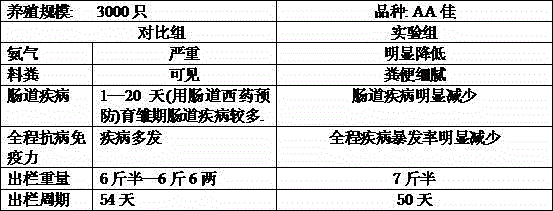

[0014] The relevant test data are as follows:

[0015] 1. Shape and color

[0016] The semi-solid is brownish-yellow or taupe; the liquid is brownish-yellow.

[0017] 2. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com