Crispy fish product and production method thereof

A fish product and crispy technology, which is applied in the field of crispy small fish products and its production, can solve the problem of less application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

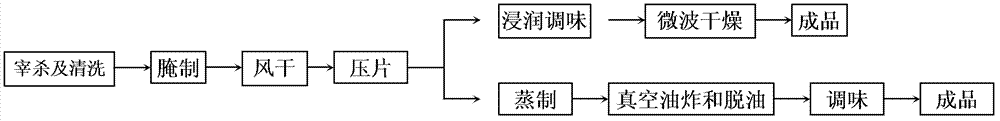

Method used

Image

Examples

Embodiment 1

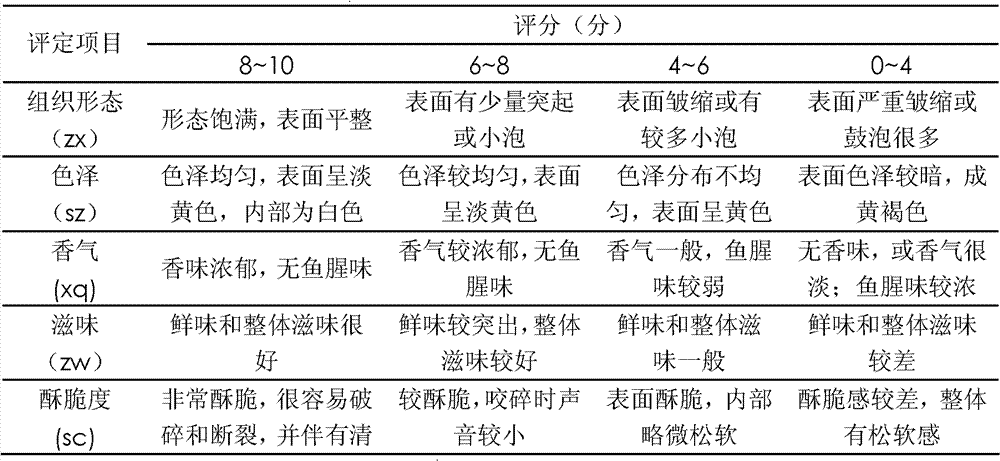

[0052]Take 10 kg of fresh carp with a body length of 5-10 cm and a body weight of 10-30 g (a freshwater fish species abundant in the middle and lower reaches of the Yangtze River, the same below), dissect it from the back, remove scales, gills and After viscera, rinse with tap water, drain the water, and marinate in 30kg of pickling solution for 3.5 hours. The preparation method of the pickling solution is: take 30kg of boiling water, add 1.2kg of salt, 0.15kg of pepper, 0.6kg of ginger slices, 0.1kg of rice wine, 0.1kg of white vinegar, 0.3kg of monosodium glutamate, and 0.3kg of white sugar powder, and use it after cooling. After pickling, put it into a drying box to dry for 5 hours. The drying temperature is 30°C, the relative humidity is 40%, and the wind speed is 3m / s. When the drying ends, the water content of the fish body is about 35%. After drying, it is flattened with a tablet press. Add 250g of water to the flattened small fish to moisten the surface of the fish bo...

Embodiment 2

[0057] Take 10kg crucian carp with a body length of 9cm-13cm and a weight of 70g-100g, cut it from the back, remove the scales, gills and viscera, rinse it with tap water, drain the water, and put it in 30kg of pickling solution Marinate for 3-4 hours. The way of pickling liquid is carried out by embodiment 1. After pickling, put it into a drying box and dry for 10 hours. The drying temperature is 30°C, the relative humidity is 40%, and the wind speed is 3m / s. When the drying finishes, the water content of the fish body is 40%. After drying, flatten with a tablet machine, and smear 100g of honey on the surface of the fish body. Finally, the microwave dosage of 7.5w / g was used to intermittently microwave the crucian carp, and every 30s was stopped for 20s, so that the total microwave treatment time was 4min. Microwave ends to get the finished product. According to the method in Table 1, the sensory evaluation of the product was carried out. The score results are as follows:...

Embodiment 3

[0059] Take 10kg of loach with a body length of 10cm-15cm and a weight of 50-80g, cut it from the back, remove the gills and internal organs, rinse it with tap water, drain the water, and marinate it in 30kg of pickling solution for 3 hours . The preparation method of pickle liquid is carried out by embodiment 1. After pickling, put it into a drying box to dry for 15 hours, so that the water content of the fish body is 42%, the drying temperature is 20°C, the humidity is 30%, and the wind speed is 3m / s. After drying, press flat with tablet machine, make fish body surface moistening with the water of 250g, then sprinkle spicy powder seasoning (purchased from Henan Xiangyi Dakitchen Seasoning Food Co., Ltd. product). Finally, the microwave dose of 10w / g was used to treat the loach with microwave, and every 20s was stopped for 20s, so that the total microwave treatment time was 5min. Microwave ends to get the finished product. According to the method in Table 1, the sensory ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com