Circulating water recycling type industrial smoke dust collection purifier

A technology for circulating water and purifiers, which is applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of high installation and construction costs, difficult to afford, and many supporting facilities, and achieves low construction and installation costs. The effect of reducing water consumption and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further illustrated below with examples, but the scope of the present invention is not limited to the category of examples. Those who achieve substantially the same purpose and achieve substantially the same effect by means of equivalent substitution are within the scope of the present invention.

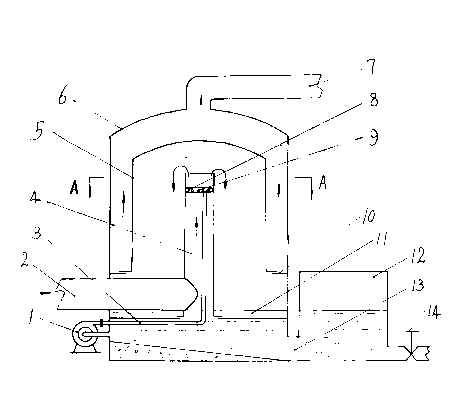

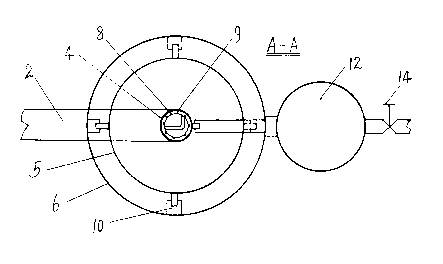

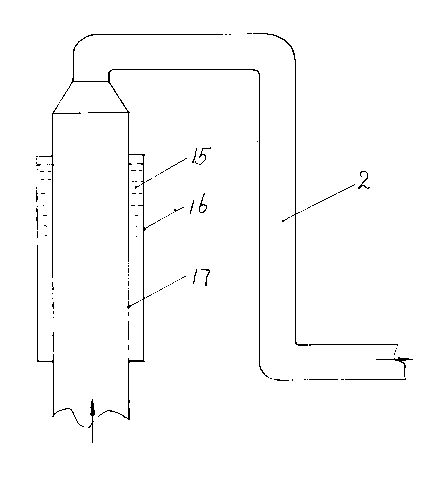

[0023] Such as Figure 1-3 shown. The outer cylinder 6, the central pipe 4, the buffer cover 5, and the smoke inlet pipe 2 and the smoke outlet pipe 7 are all welded with aluminum plates or steel plates. The diameter of the outer cylinder is 4 meters, and the height is 5 meters. An annular water pipe 8 is housed, and the inner side of the annular water pipe has many water spray eyes 9, and the water spray eyes point to the center of the ring, and the lower end of the high-pressure water pipe 3 directly communicates with the pump 1, and the upper end links to each other with the annular water pipe. When the pump works, the water in the rinsing pool i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com