Co-based supported catalyst for catalytic removal of benzene-series compounds in air and preparation method thereof

A technology of supported catalyst and benzene series, which is applied in the field of Co-based supported catalyst and its preparation, can solve the problems of high reaction temperature and low removal rate of benzene series, achieve good repeatability, good catalytic combustion activity, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

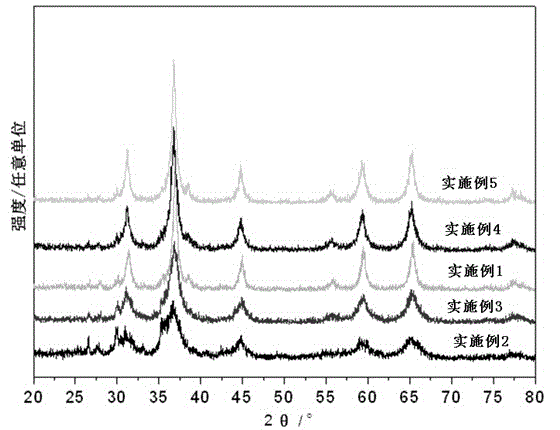

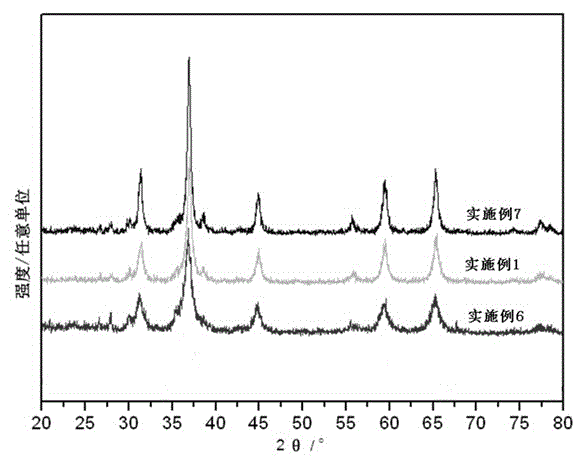

Embodiment 1

[0023] The catalyst of this embodiment includes the active component Co 3 o 4 and carrier activated carbon, Co 3 o 4 The weight ratio with activated carbon is 2:8.

[0024] The preparation method of the catalyst of the present embodiment comprises the following steps:

[0025] 1) Press CO 3 o 4 The amount of cobalt nitrate was weighed and fully dissolved in distilled water, then 20~80 mesh activated carbon particles were impregnated in the obtained cobalt nitrate solution, evaporated to dryness at 70°C under constant stirring, and then dried at a constant temperature of 100°C for 24 h (The purpose of drying at a constant temperature of 100°C is to remove the crystal water in the raw material, and the drying time here is 10~24h, which can achieve the purpose of the invention) to obtain a dry material;

[0026] 2) The dry material prepared in step 1) was heated in a muffle furnace to 350° C. at a heating rate of 10° C. / min, and then calcined at a constant temperature of 35...

Embodiment 2

[0028] The catalyst of this embodiment includes the active component Co 3 o 4 and carrier activated carbon, Co 3 o 4 The weight ratio with activated carbon is 1:9.

[0029] The preparation method of the catalyst of this embodiment is the same as that of Example 1.

Embodiment 3

[0031] The catalyst of this embodiment includes the active component Co 3 o 4 and carrier activated carbon, Co 3 o 4 The weight ratio with activated carbon is 1.5:8.5.

[0032] The preparation method of the catalyst of this embodiment is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com