Partial cooling method of cold iron in investment casting

A technology of investment casting and local cooling, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problem that cold iron cannot be reused, and achieve the effect of enhancing local chilling effect and local heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] A method for local cooling of an investment casting cold iron of the present invention comprises the following steps:

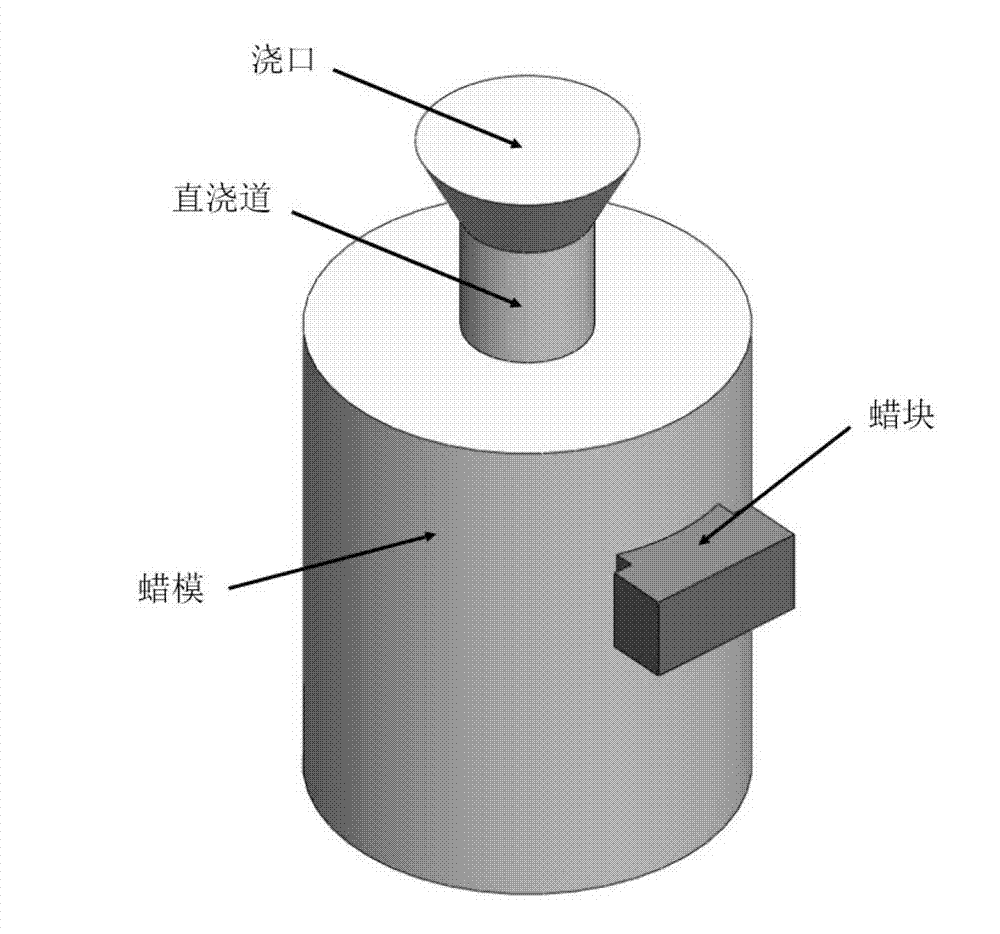

[0023] Step 1: First, press the wax mold and weld the gating system according to the normal investment casting process;

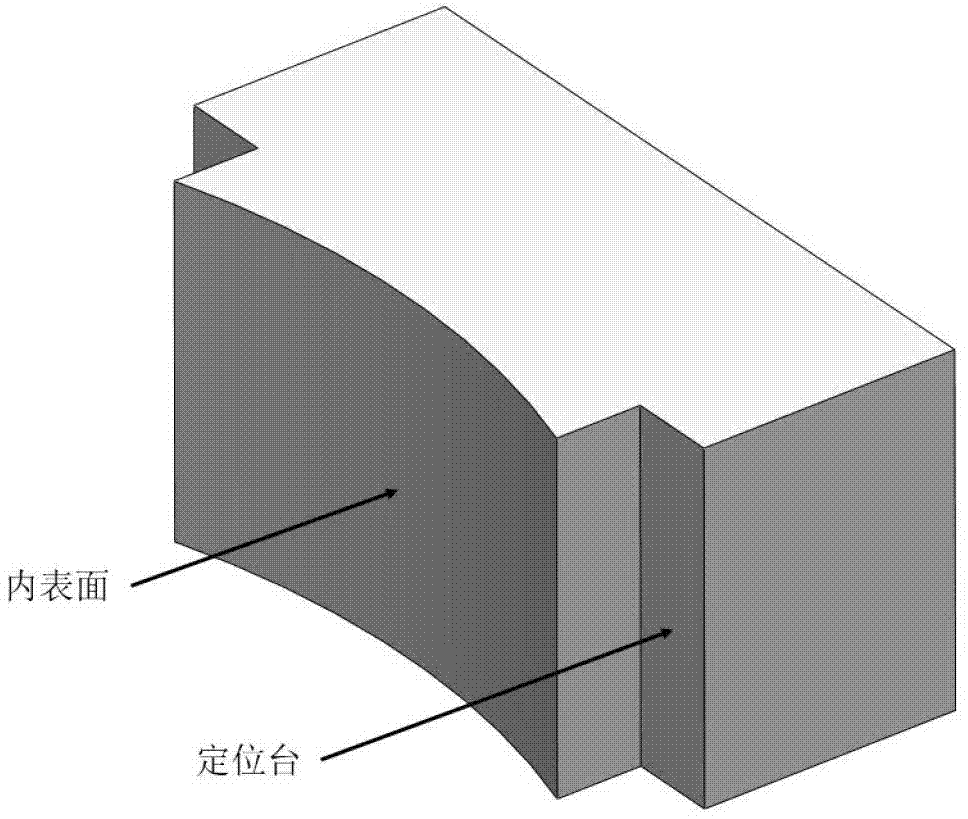

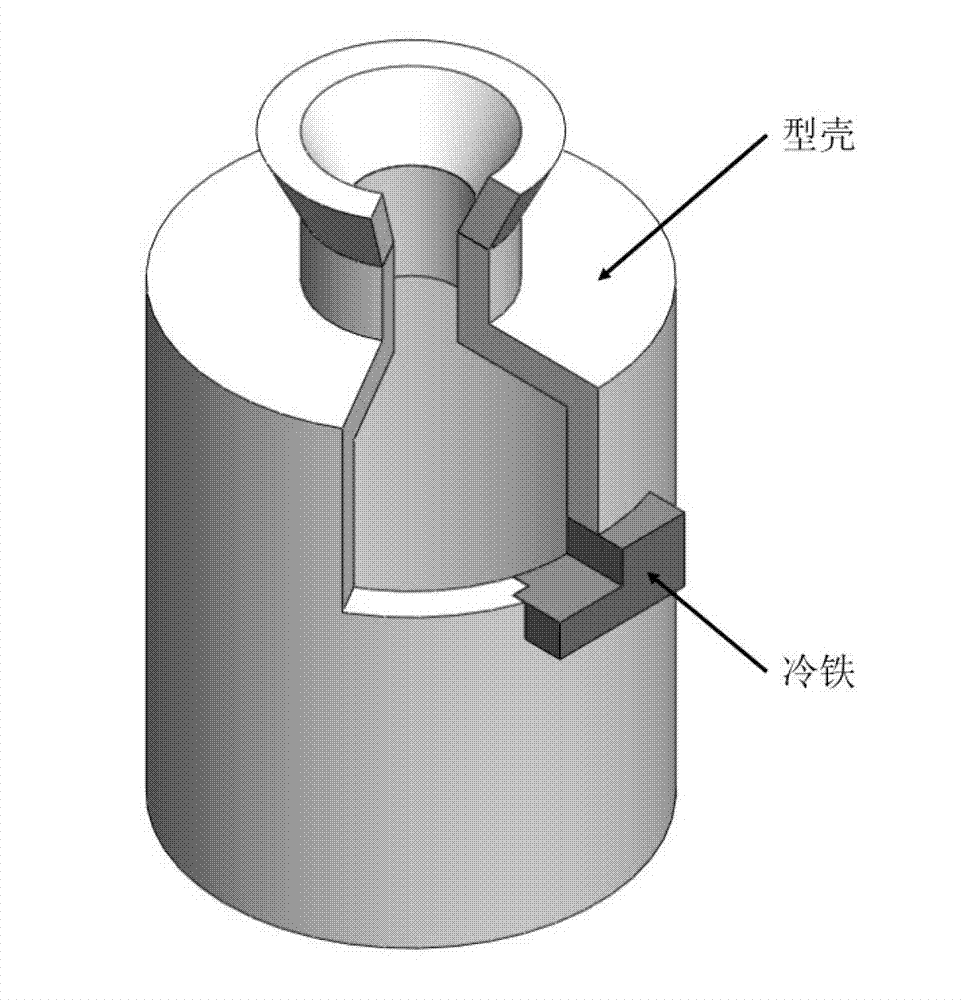

[0024] Step 2: Design the chill iron and the wax block with the same shape and size as the chill iron according to the outer surface shape of the hot joint of the casting. The inner surface of the designed chill iron and wax block fits the outer surface shape of the hot joint of the casting, and Make the cold iron and wax block with positioning steps, then make the cold iron and wax block; as in figure 1 The schematic diagram of the cold iron is shown. It should be ensured that the inner surface of the cold iron can fit closely with the outer wall of the hot joint of the casting. At the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com