Powder metallurgical formulas for internal and external rotors of hydraulic slippage pump and manufacturing method of internal and external rotors of hydraulic slippage pump

A powder metallurgy and oil charge pump technology, applied in the field of powder metallurgy, can solve the problems of damage to main pump parts, economic losses, inconvenient maintenance work, etc., and achieve the effect of satisfying long-term load operation, reducing economic losses, and preventing impact deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

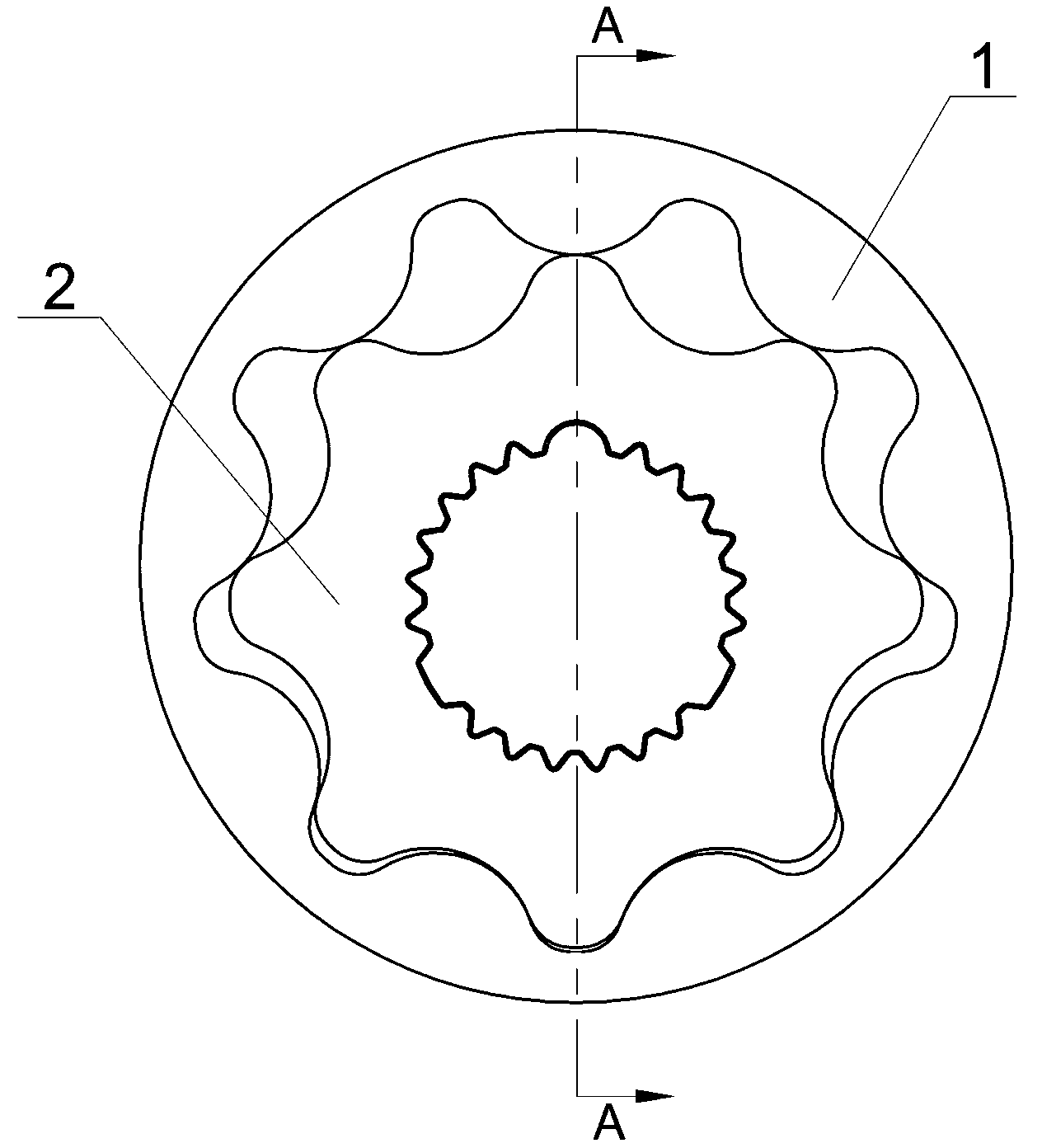

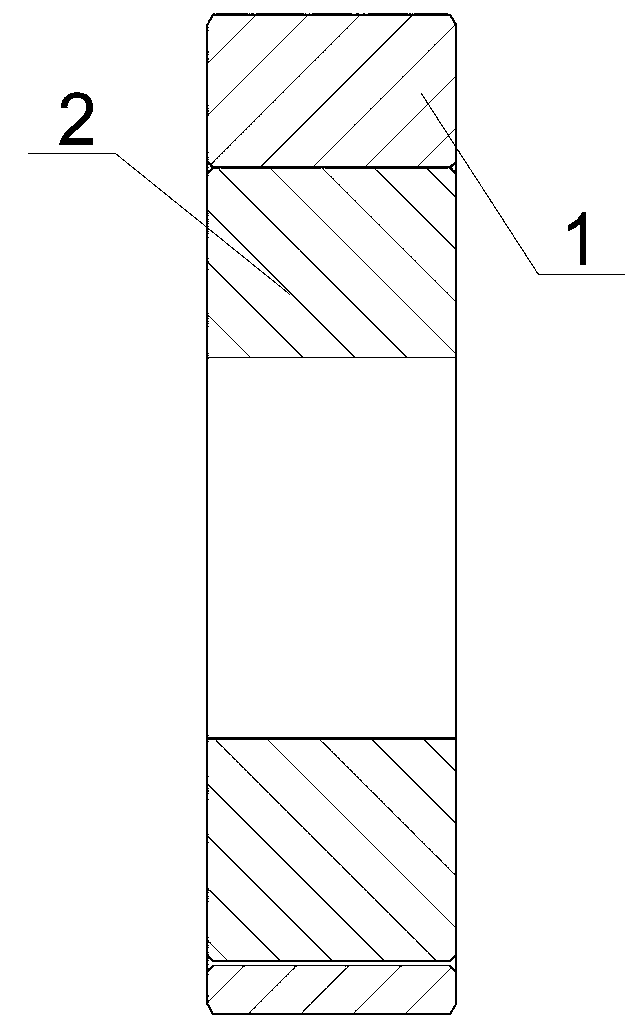

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0029] The powder metallurgy formula of the inner and outer rotors of the hydraulic charge pump, according to the actual working conditions and the structural force analysis of each component, the powder metallurgy formula of the inner rotor and the outer rotor adopts two different formulas, and is equipped with different heat treatment processes to meet actual needs. , which can not only meet the needs of conventional working conditions, but also solve the problems in the technical background. The specific raw material ratio is as follows:

[0030] Inner rotor: carbon 0.7-0.9%, nickel 2-3%, copper 1.5-2.5%, the balance is iron powder;

[0031] Outer rotor: carbon 0.5-0.8%, nickel 0.5-1.8%, molybdenum 2-3%, manganese 2-3%, and the balance is iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com