Special automatic regulating device for taper error of centerless internal grinding machine

A technology of taper adjustment and automatic adjustment, which is applied in the directions of automatic grinding control devices, grinding machine parts, grinding/polishing equipment, etc., which can solve the problem of automatic adjustment of taper error of centerless internal grinding machines and difficulty in ensuring repeat positioning accuracy , Reduce production efficiency and other issues, achieve low cost, ensure processing efficiency, and the effect of simple and fast process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

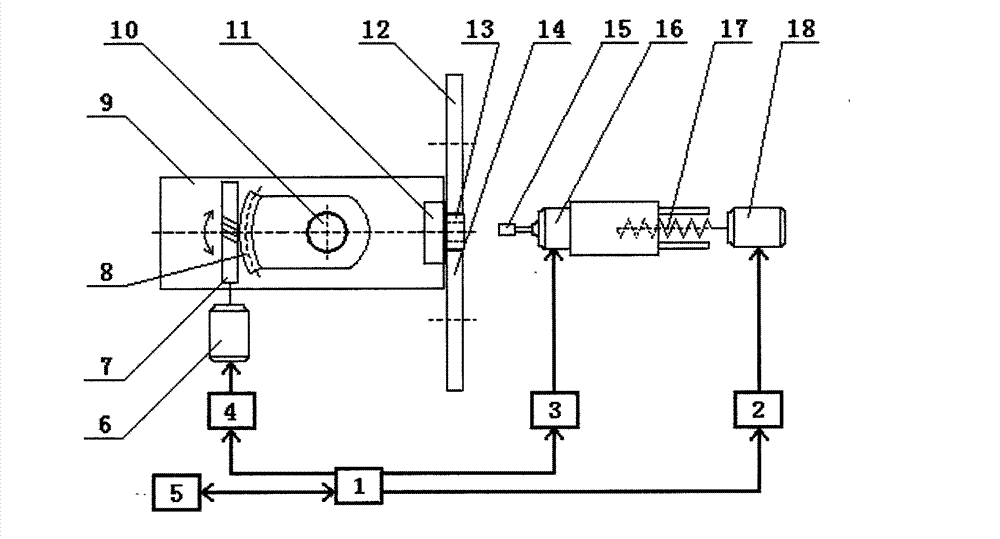

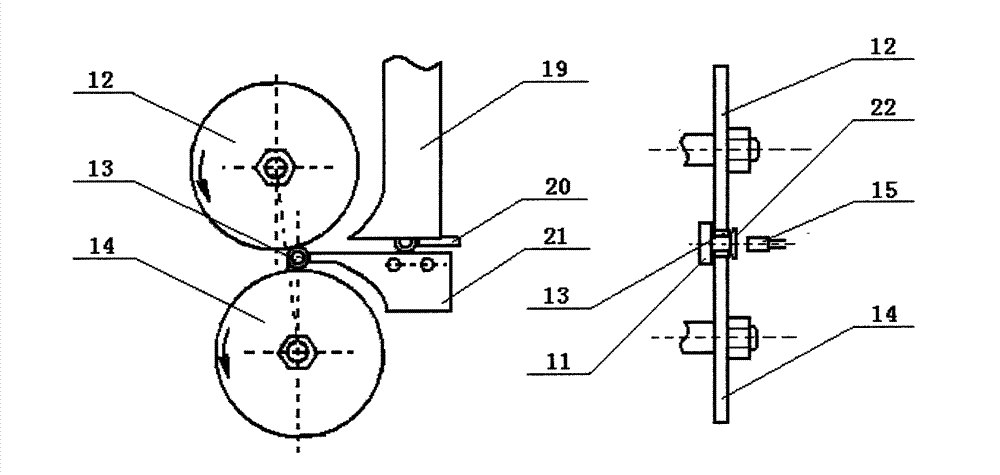

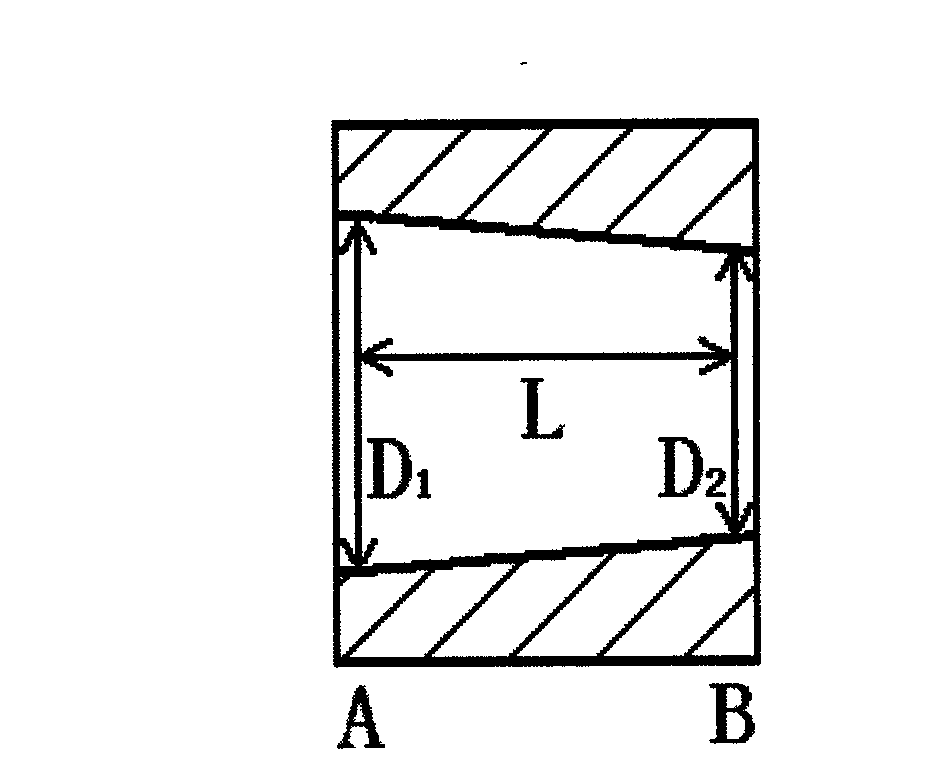

[0028] The structure diagram of the taper error automatic adjustment device for centerless internal grinder of the present invention is as follows figure 1 As shown, in the device, the PLC (1) is respectively connected with the grinding wheel shaft stepping motor driver (2), the grinding wheel electric spindle driver (3), the taper adjusting stepping motor driver (4) and the touch screen (5); The grinding wheel shaft stepping motor driver (2) is connected with the grinding wheel shaft stepping motor (18); the grinding wheel electric spindle drive (3) is connected with the grinding wheel electric spindle (16); the taper adjusting stepping motor driver (4) ) Is connected to the taper adjusting stepper motor (6); the taper adjusting stepper motor (6) is connected to the taper adjusting worm (7); the taper adjusting worm (7) is connected to the taper adjusting worm wheel (8); The taper adjusting worm wheel (8) is a part of the rotatable workpiece table (9); the rotatable workpiece t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com