Dynamic regulation method of VOD refined end point carbon content prediction model

A technology of end-point carbon content and prediction model, which is applied in the field of dynamic adjustment of VOD refining prediction model, can solve problems such as difficult to guarantee product quality and smelting cost, and achieve the effects of shortening smelting time, improving control level, and reducing gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

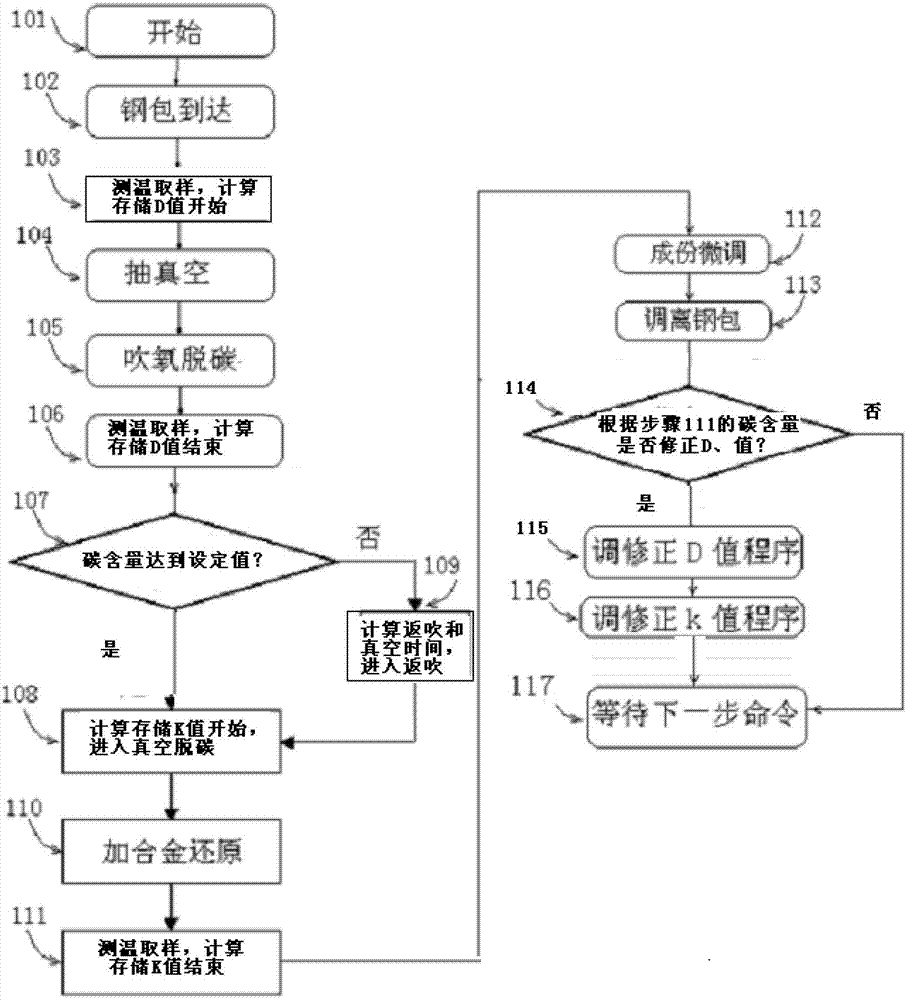

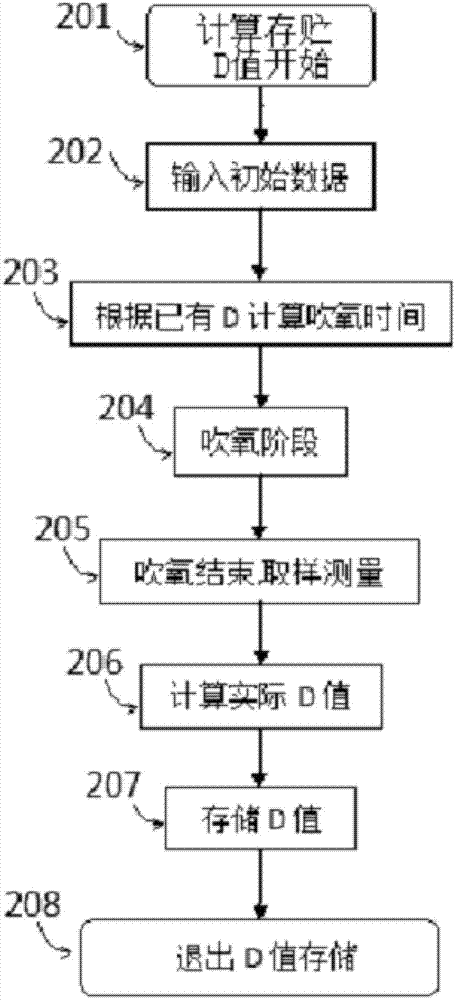

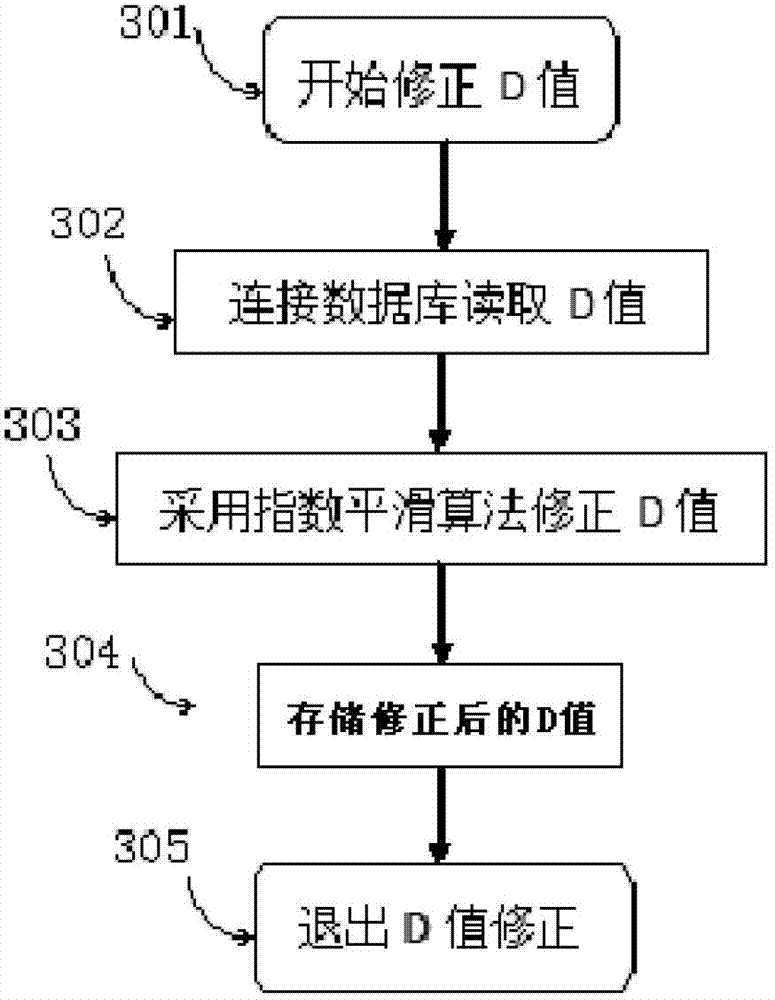

[0064] VOD process flow such as figure 1As shown, it can be divided into three stages: oxygen blowing decarburization, vacuum decarburization, and feeding reduction. The technological process is as follows: when the ladle containing molten steel and slag dumped is transported to the VOD processing station, the argon valve is opened, and argon is blown at the bottom of the ladle. Then, temperature measurement and sampling are carried out, and after the initial smelting data are obtained, the vacuum cover is covered to completely seal the vacuum tank. The vacuum pump system starts working. As the pressure drops, the decarburization process begins. When the vacuum degree reaches a certain value, the oxygen lance moves to the preset position to start the oxygen blowing process. After the oxygen blowing is over, it is necessary to break the vacuum for sampling and testing to obtain the temperature of the molten steel after the oxygen blowing and the content of each main element....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com