Electrostatic spinning device capable of adjusting spinning temperature and humidity

An electrostatic spinning and adjustable technology, which is applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of spinning temperature and humidity control, etc., and achieve the effect of convenient operation, simple control, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

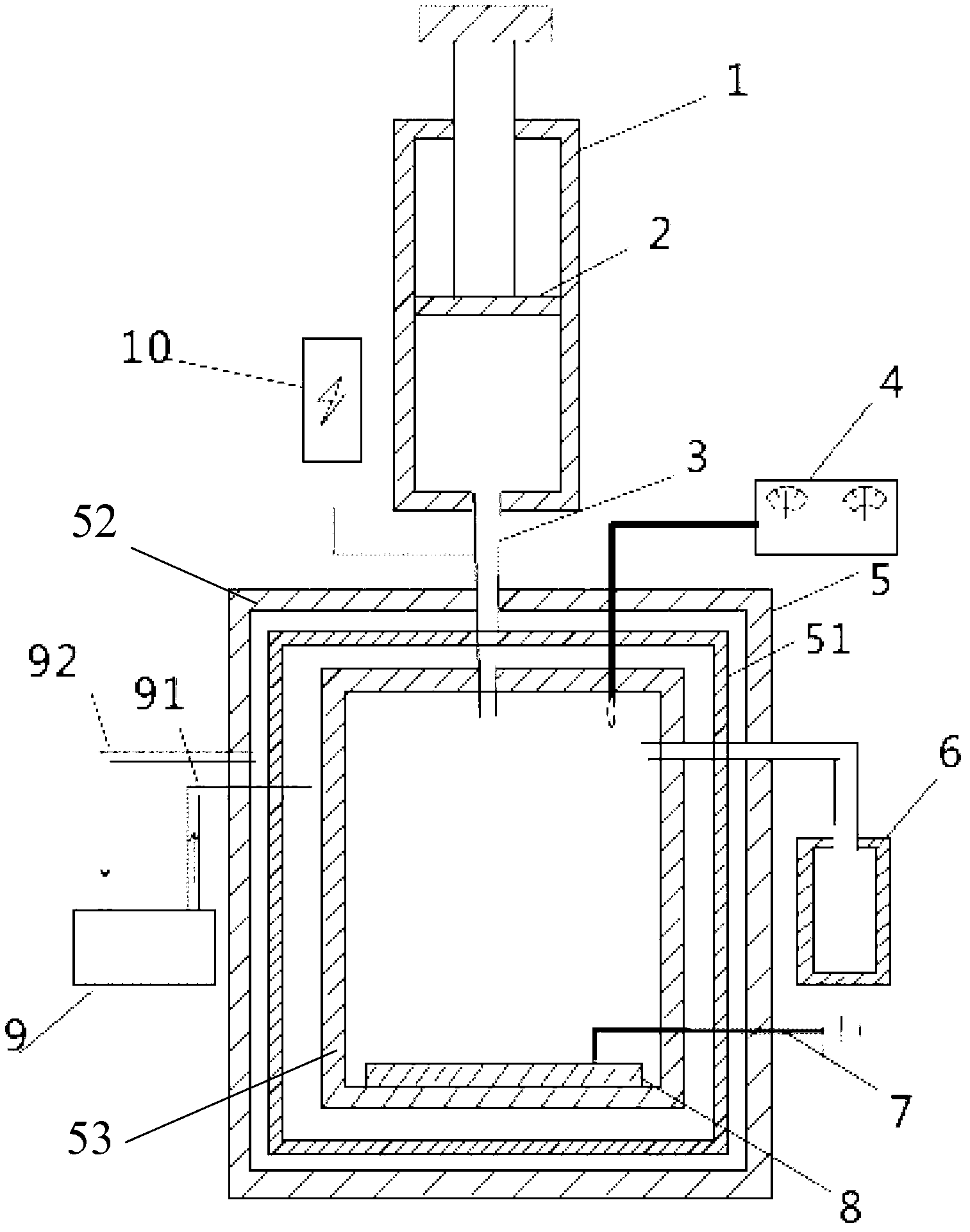

[0021] The invention discloses an electrostatic spinning device capable of adjusting spinning temperature and humidity, which is used to solve the technical problem of spinning temperature and humidity regulation in the electrostatic spinning process.

[0022] The electrostatic spinning device with adjustable spinning temperature and humidity includes a material barrel, a piston arranged in the material barrel and capable of moving in the material barrel, a spinneret arranged at one end of the material barrel and communicated with the material barrel, connected to the The high-voltage power supply device on the spinneret, the receiving plate corresponding to the position of the spinneret, and the grounding power line for the grounding of the receiving plate, the electrostatic spinning device also includes a cover on the periphery of the spinneret to form a closed spinning area Double-layer glass cover, interlayer space located between the double-layer glass cover, temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com