Sound-absorption heat-insulation floor and processing method thereof

A processing method and flooring technology, applied in chemical instruments and methods, layered products, construction, etc., can solve problems such as physical performance mismatch, environmental hazards, shock absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

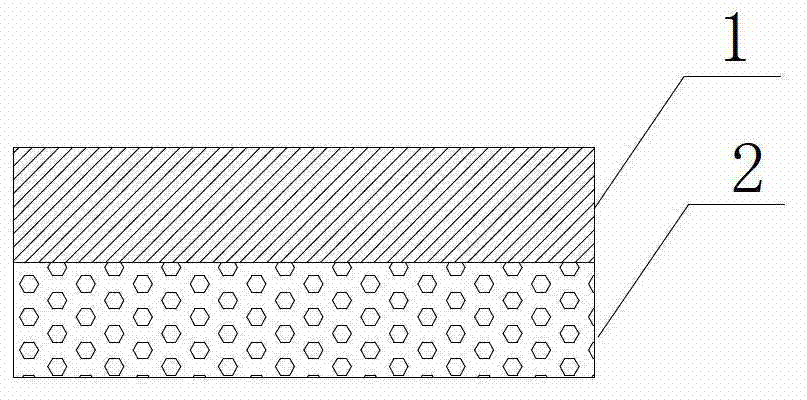

[0027] Embodiment 1 discloses a sound-absorbing and heat-insulating floor, which combines figure 1 , including a surface layer and a bottom layer, the bottom layer is attached below the surface layer, the surface layer is a PVC sheet layer 1, and the bottom layer is a PVC foam coil layer 2.

[0028] A glass fiber mat is added in the PVC foamed coil layer 2 (in other embodiments, at least one of glass fiber mat, glass fiber mesh and non-woven fabric is added in the PVC foamed coil layer 2).

[0029] The expansion ratio of the PVC foamed coil layer 2 is 2 times (in other embodiments, the expansion ratio of the PVC foamed coil layer 2 is 0.5-3.0 times).

[0030] The thickness of the surface layer is 3.0 mm, and the thickness of the bottom layer is 3.5 mm (in other embodiments, the thickness of the surface layer is 1.0-5.0 mm, and the thickness of the bottom layer is 0.5-5.0 mm).

[0031] The PVC sheet layer 1 adopts a multi-layer composite type, and from top to bottom is a wear-...

Embodiment 2

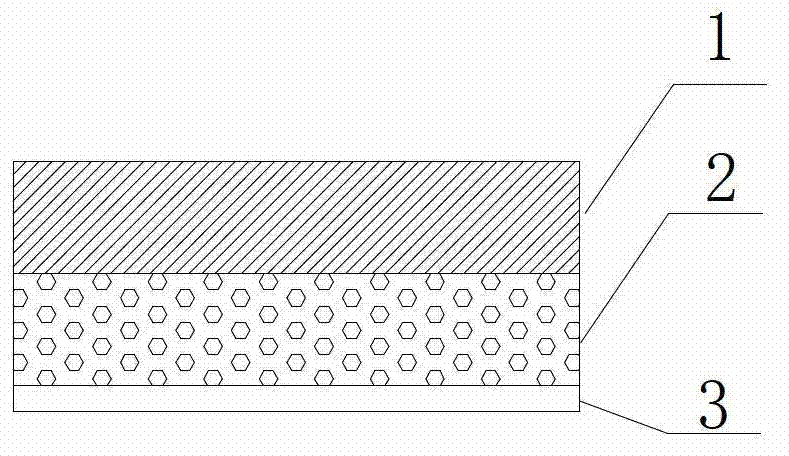

[0038] Embodiment 2 discloses a sound-absorbing and heat-insulating floor, which combines figure 2 , including a surface layer and a bottom layer, the bottom layer is attached below the surface layer, the surface layer is a PVC sheet layer 1, and the bottom layer is a PVC foam coil layer 2 and other polymer material layers 3 from top to bottom, in this embodiment , the other polymer material layer 3 is TPU (in other embodiments, the other polymer material layer 3 is at least one of TPU, TPR and EVA).

[0039] A glass fiber mesh is added in the PVC foaming coil layer 2 .

[0040] The expansion ratio of the PVC foamed coil layer 2 is 3 times (in other embodiments, the expansion ratio of the PVC foamed coil layer 2 is 0.5-3.0 times).

[0041] The thickness of the surface layer is 1.0 mm, and the thickness of the bottom layer is 5.0 mm (in other embodiments, the thickness of the surface layer is 1.0-5.0 mm, and the thickness of the bottom layer is 0.5-5.0 mm).

[0042] The PVC ...

Embodiment 3

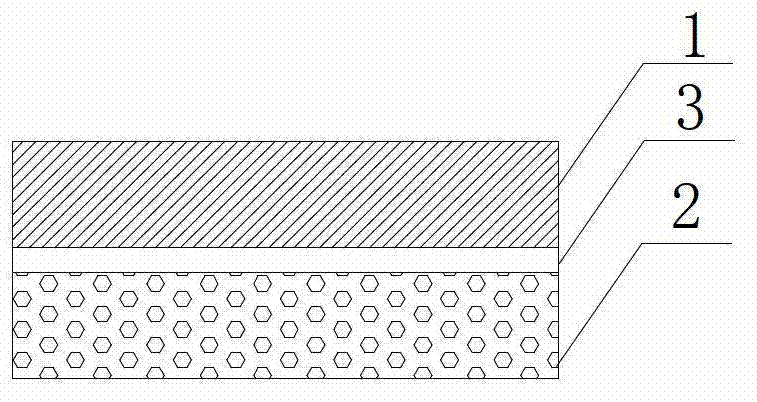

[0045] Embodiment 3 discloses a sound-absorbing and heat-insulating floor, which combines image 3 , including a surface layer and a bottom layer, the bottom layer is attached below the surface layer, the surface layer is a PVC sheet layer 1 and other polymer material layers 3 from top to bottom, the bottom layer is a PVC foam coil layer 2, and other The polymer material layer 3 is TPR.

[0046] A non-woven fabric is added in the PVC foamed coil layer 2 .

[0047] The expansion ratio of the PVC foam coil layer 2 is 0.5 times (in other embodiments, the expansion ratio of the PVC foam coil layer 2 is 0.5-3.0 times).

[0048] The thickness of the surface layer is 5.0 mm, and the thickness of the bottom layer is 0.5 mm (in other embodiments, the thickness of the surface layer is 1.0-5.0 mm, and the thickness of the bottom layer is 0.5-5.0 mm).

[0049] The PVC sheet layer 1 adopts a multi-layer composite type, and from top to bottom is a wear-resistant layer, a pattern printing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com