System and method of directing-type rotary steering actuator mandrel displacement vector control

An actuator and rotary steerable technology, applied in drilling automatic control system, measurement, directional drilling, etc., can solve problems such as poor miniaturization ability, high precision requirements, and easy oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

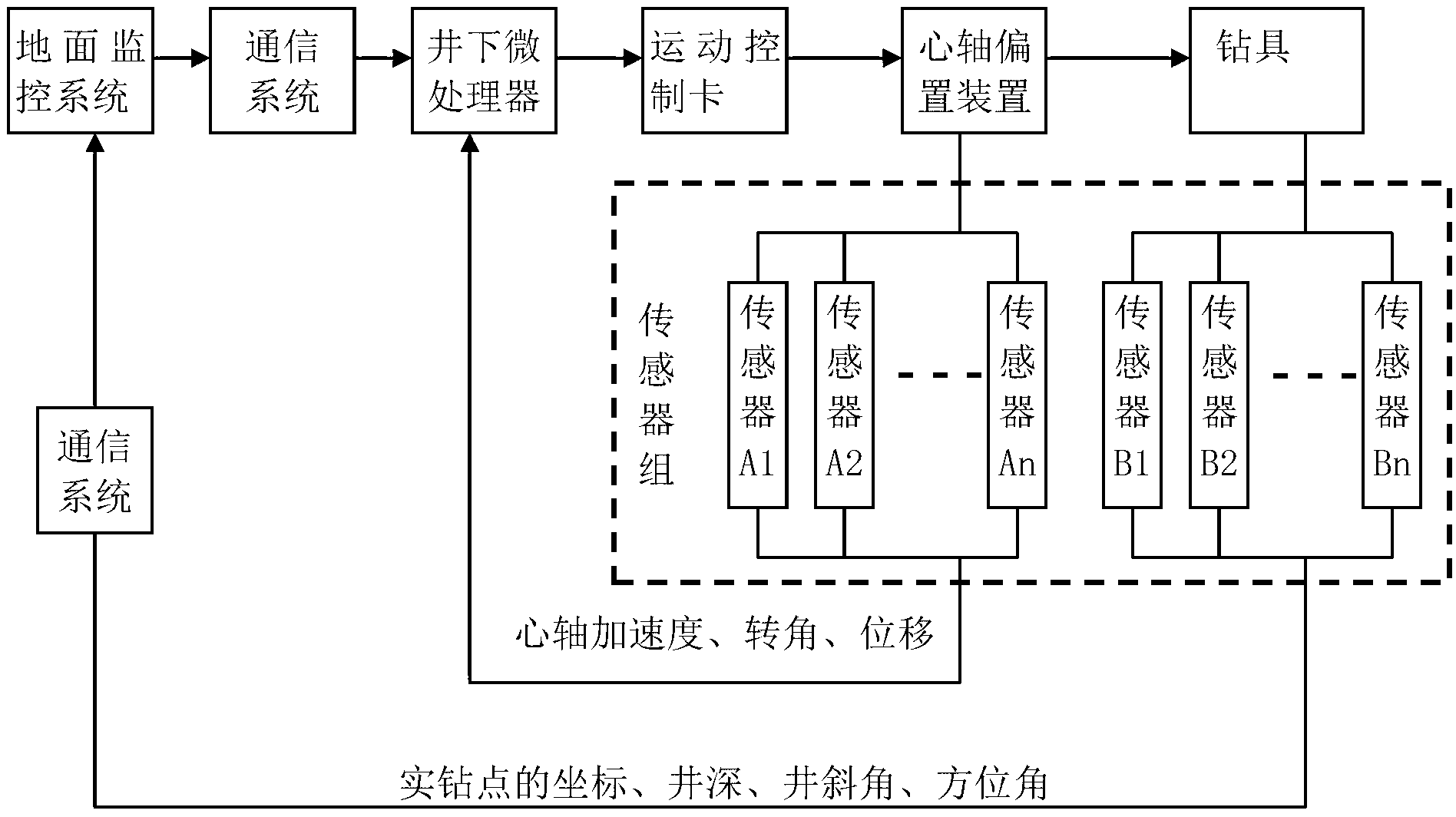

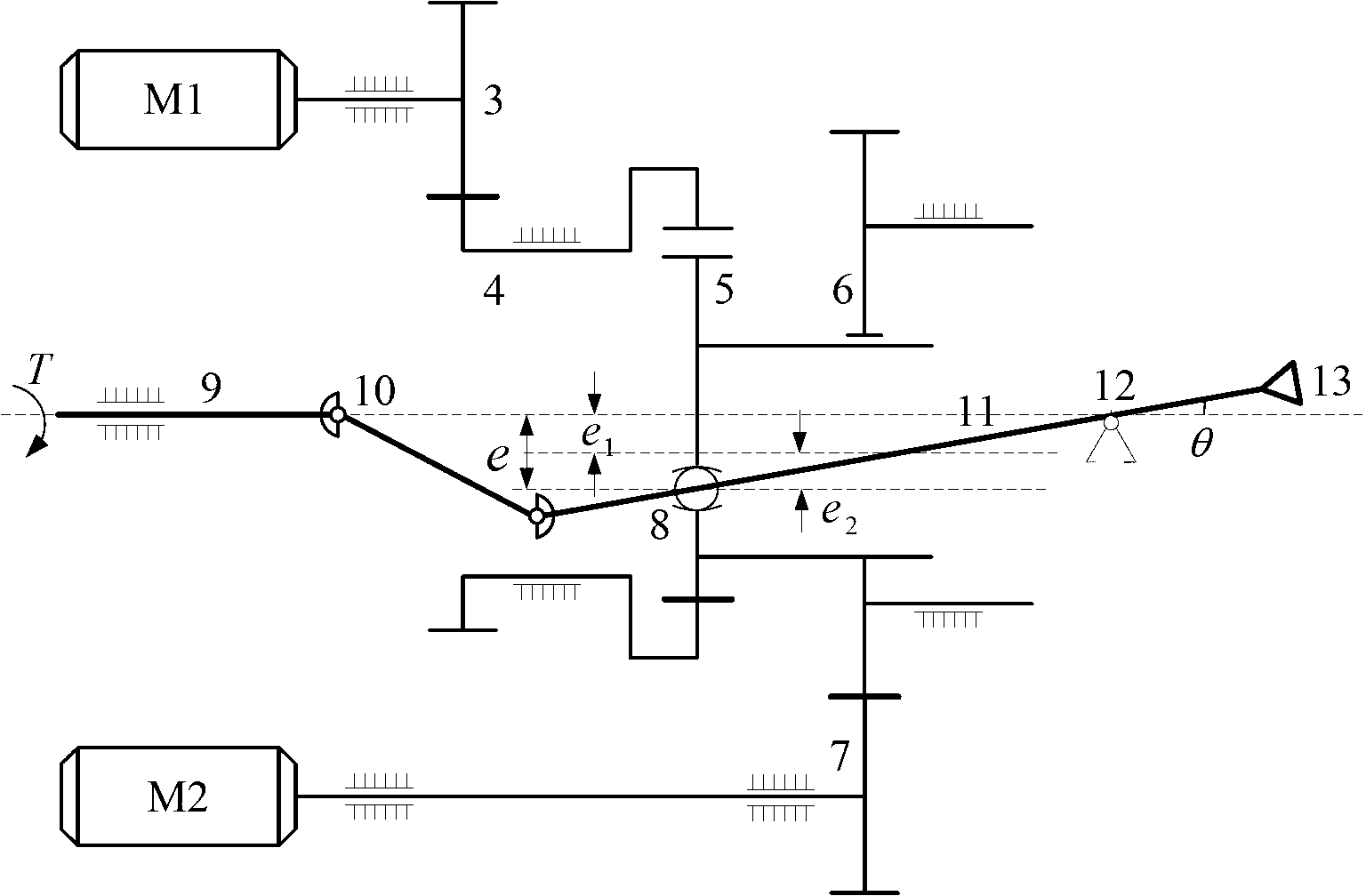

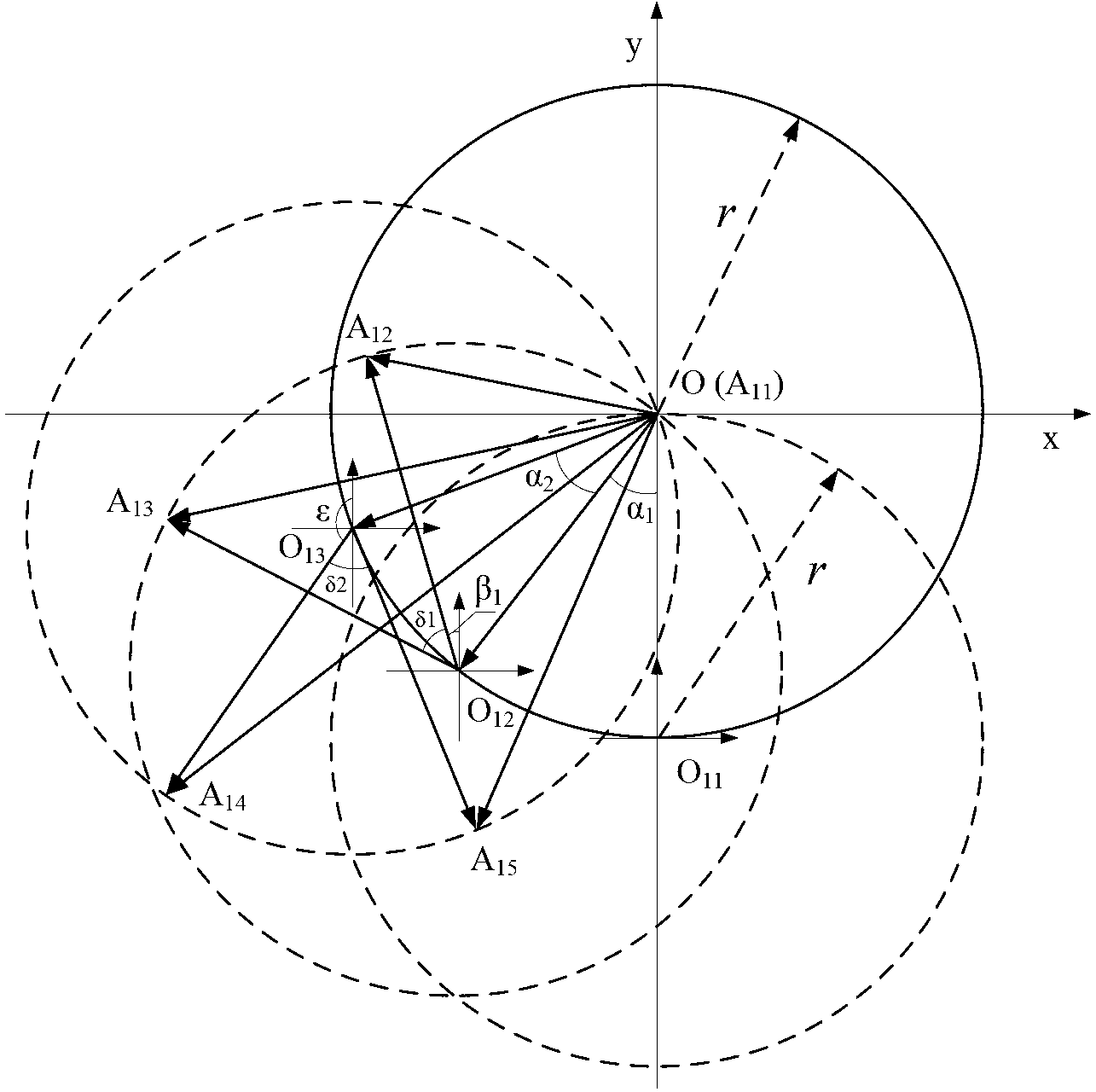

[0052] see Figure 1 ~ Figure 3 , a pointing rotary steerable actuator mandrel displacement vector control system, the system is a double closed-loop structure, including a surface monitoring system, a communication system for data transmission between the surface and downhole devices, and a downhole microprocessor located downhole , a motion control card, a mandrel bias device and a sensor group; the sensor group detects the actual drilling data of the drilling tool and the displacement data of the mandrel, such as figure 1 As shown, sensors A1~sensor An represent multiple sensors for detecting information such as mandrel eccentricity displacement vector attitude, and sensors B1~sensor Bn represent the coordinates of the actual drilling poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com