Metal-surface wall thickness detector with probes distributed in matrix mode and measurement method thereof

A matrix distribution, metal technology, applied in the field of new non-destructive testing devices, can solve the problems of large measurement error, long measurement time, low sensitivity, etc., and achieve the effects of small measurement error, high work efficiency, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

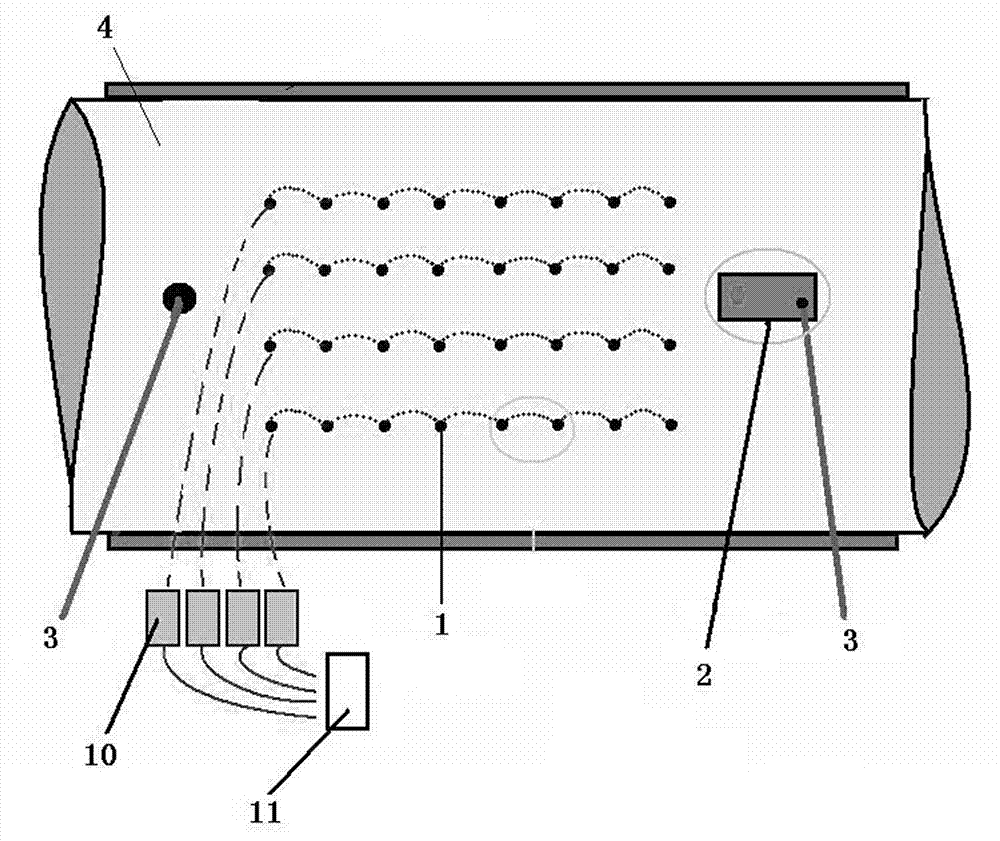

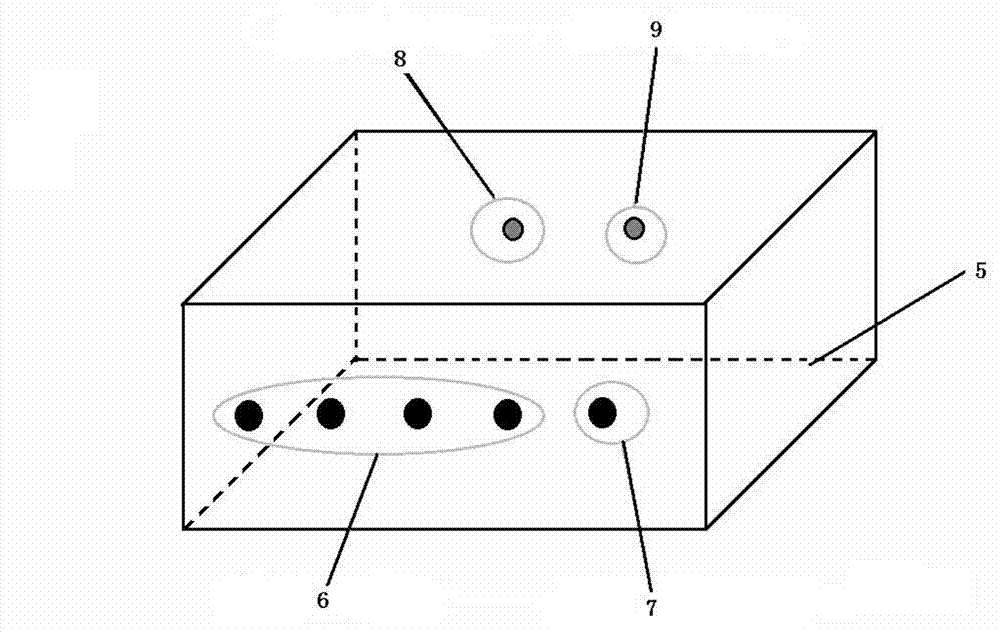

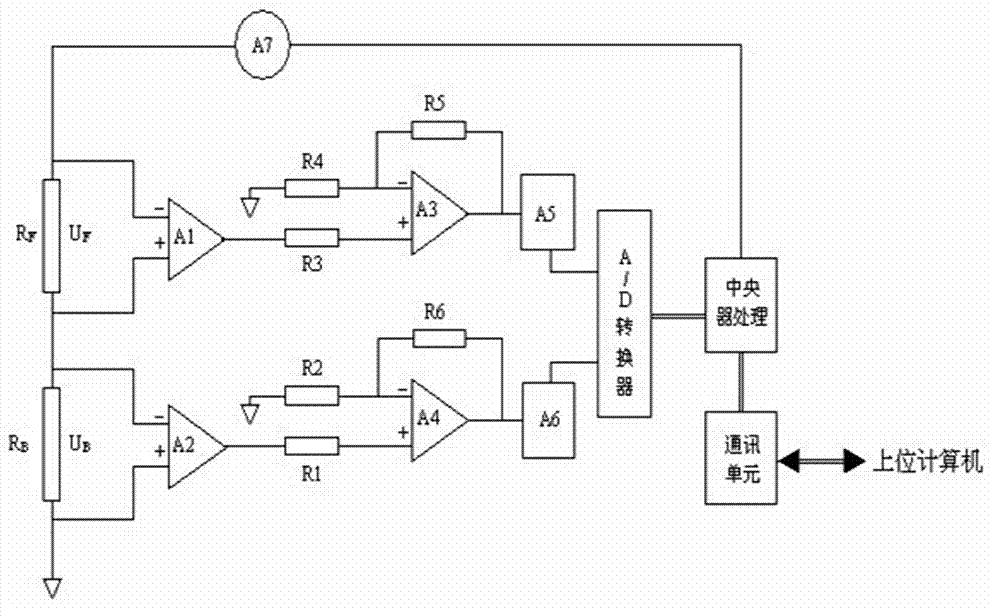

[0021] Such as figure 1 , figure 2 As shown, the metal surface wall thickness detector with probes distributed in a matrix of the present invention includes three parts: a probe matrix group, a connector and a collector. The probe matrix group includes: a probe 1, a compensation test block 2, and an excitation signal electrode 3. The probe 1 is a columnar electrode, which is used to test the corrosion rate of the metal; the compensation test block 2 is set on the surface of the tested pipeline 4, and one end thereof is closely connected with the tested pipeline 4, and is used for temperature compensation of the tested pipeline 4; The excitation signal electrode 3 is used to provide the excitation signal; the present embodiment adopts the same material as the monitoring equipment, such as carbon steel, etc., for testing the corrosion rate of the metal; the compensation test block 2 is the same metal material as the measured metal, and is used for Temperature compensation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com