Object vibration spectrum measurement system based on laser

A vibration spectrum and measurement system technology, which is applied to measurement devices, ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems that the acoustic wave method is susceptible to environmental interference and measurement errors, and achieves strong anti-interference ability and good stability. , the effect of real-time storage and reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

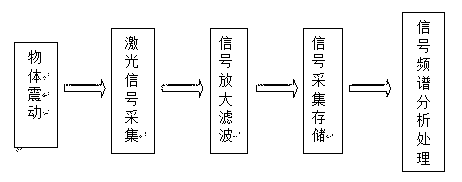

[0011] figure 1 It means that the system is mainly composed of four parts: signal acquisition, signal filtering and amplification, signal sampling and storage, and signal transformation.

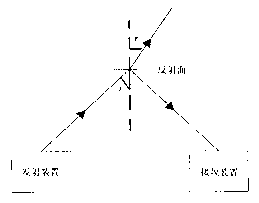

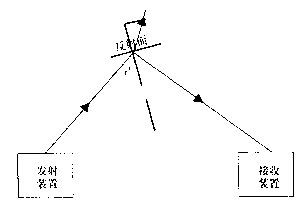

[0012] exist figure 2 with image 3 In , it means that when the measured object vibrates, the vibration causes the incident angle of the laser to change under the condition that the incident direction remains unchanged. The reflection law and refraction law of light are used to deduce the reflected laser Poynting vector as The angle of incidence changes so that the reflected laser light is modulated by the vibrations of the object.

[0013] Figure 4 Represents the signal acquisition part of the circuit, where LED1 and LED2 represent photocells respectively, and their positions are placed at 45 degrees to each other. The two photocells convert optical signals into electrical signals. Three OPA2107 constitute a precision instrument amplifier circuit (equivalent to AD620), and differentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com