Hydrophobic fluorinated coatings

A hydrophobic, fluorinated layer technology, used in coatings, metal material coating processes, silicon compounds, etc., can solve problems such as depletion of fluorine-containing compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

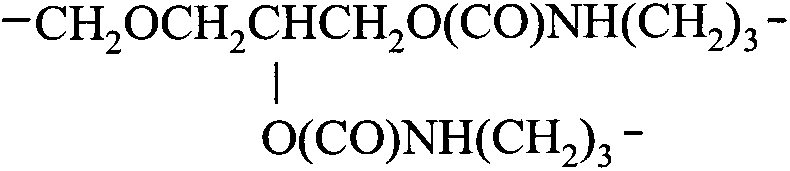

Method used

Image

Examples

example

[0252] Objects and advantages of this invention are further illustrated by the following examples, but the particular materials and amounts thereof recited in these examples, as well as other conditions and details, should not be construed to unduly limit this invention. These examples are for illustrative purposes only and are not intended to limit the scope of the appended claims.

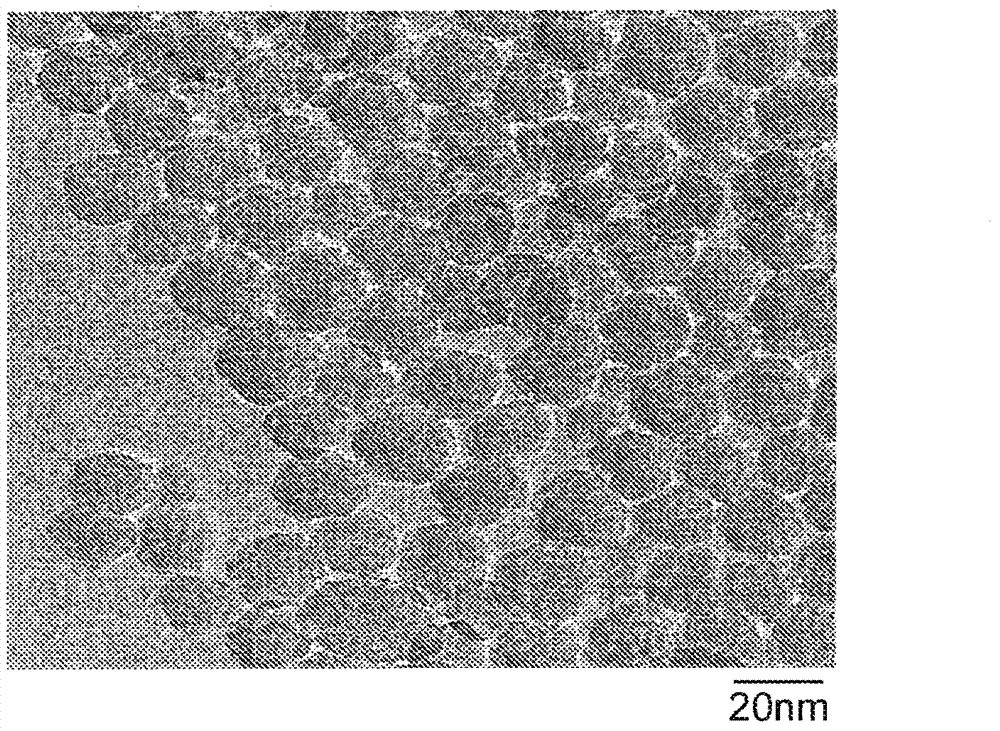

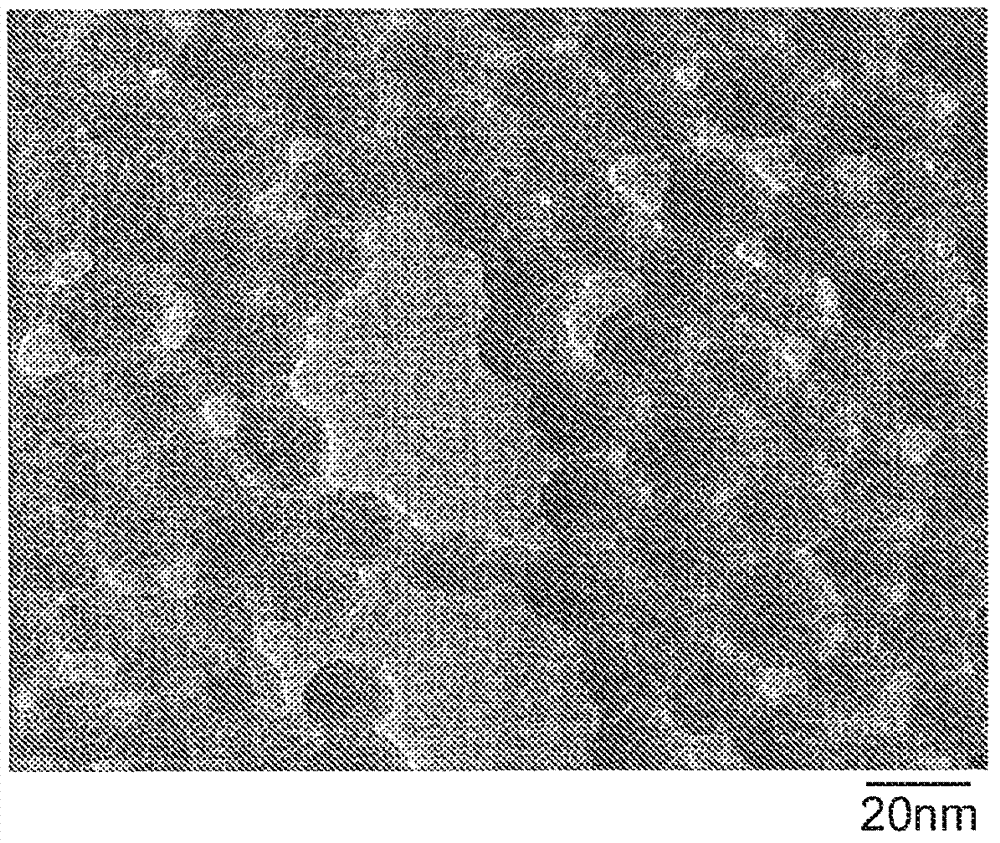

[0253] Material Glossary

[0254] "NALCO 1115" refers to an aqueous colloidal spherical bismuth with 16.5 wt% solids (nominal 16 wt% solids) commercially available from NALCO Chemical Company, Naperville, IL. Silica dispersion with an average particle size of about 4 nm.

[0255] "NALCO 1050" refers to an aqueous colloidal spherical bismuth having 50.4 wt% solids (nominal 50 wt% solids) commercially available from NALCO Chemical Company, Naperville, IL. Silica dispersion with an average particle size of about 20 nm.

[0256] "NALCO TX11561" refers to an aqueous colloidal spherical bismuth wi...

example 1-6 and comparative example A

[0337] For each of Examples 1 to 6, a glass plate measuring 5.1 cm x 7.6 cm was immersed in a cleaning solution of sulfuric acid and hydrogen peroxide (volume ratio (v / v) of sulfuric acid to hydrogen peroxide was 3:1) for 30 minute. Afterwards, the glass plate was rinsed with deionized water and dried by nitrogen flow. Each glass plate was dipped into the primer coating composition (PLC) at a rate of 10.8 centimeters per minute (cm / min), held in the primer coating composition for 20 seconds, and then at a rate of 10.8 cm / min. Remove from primer coat composition. Examples 1 to 6 were immersed in PLC1 to PLC6, respectively. Each primer layer was dried at room temperature and then heated at 200° C. for 30 minutes. Each sample was then dipped into the fluorinated layer coating composition (FLC1 ) using the same coating process used for the primer layer coating composition. Each sample was then dried at room temperature and subjected to a final heat treatment at 120°C for 30 mi...

example 7-12 and comparative example B

[0343] For each of Examples 7 to 10, a stainless steel coupon measuring 5.1 cm x 7.6 cm was immersed in a sulfuric acid and hydrogen peroxide cleaning solution (volume ratio (v / v) of sulfuric acid to hydrogen peroxide was 3:1 ) 120 minutes. Thereafter, each stainless steel coupon was rinsed with deionized water and dried by nitrogen flow. Each stainless steel coupon was immersed in the primer coating composition (PLC) at a rate of 11.5 centimeters per minute (cm / min), held in the primer coating composition for 30 seconds, and then dipped in the primer coating composition at 11.5 cm / min. The rate of removal from the primer layer coating composition. Examples 7, 8, 10, 11 and 12 were dipped into PLC9 and Example 9 into PLC7. Each primer layer was dried at room temperature and then heated at 150° C. for 10 minutes. Each sample was then dipped into the fluorinated layer coating composition shown in Table 2. The same coating process used for the primer layer coating composition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com