Epoxy resin composition, prepreg, metal-clad laminate, printed wiring board and semiconductor device

一种覆金属层压板、印刷布线板的技术,应用在金属层状产品、印刷电路、印刷电路等方向,能够解决粘连、操作困难、粘性大等问题,达到提高耐热性和阻燃性、操作容易、粘性良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

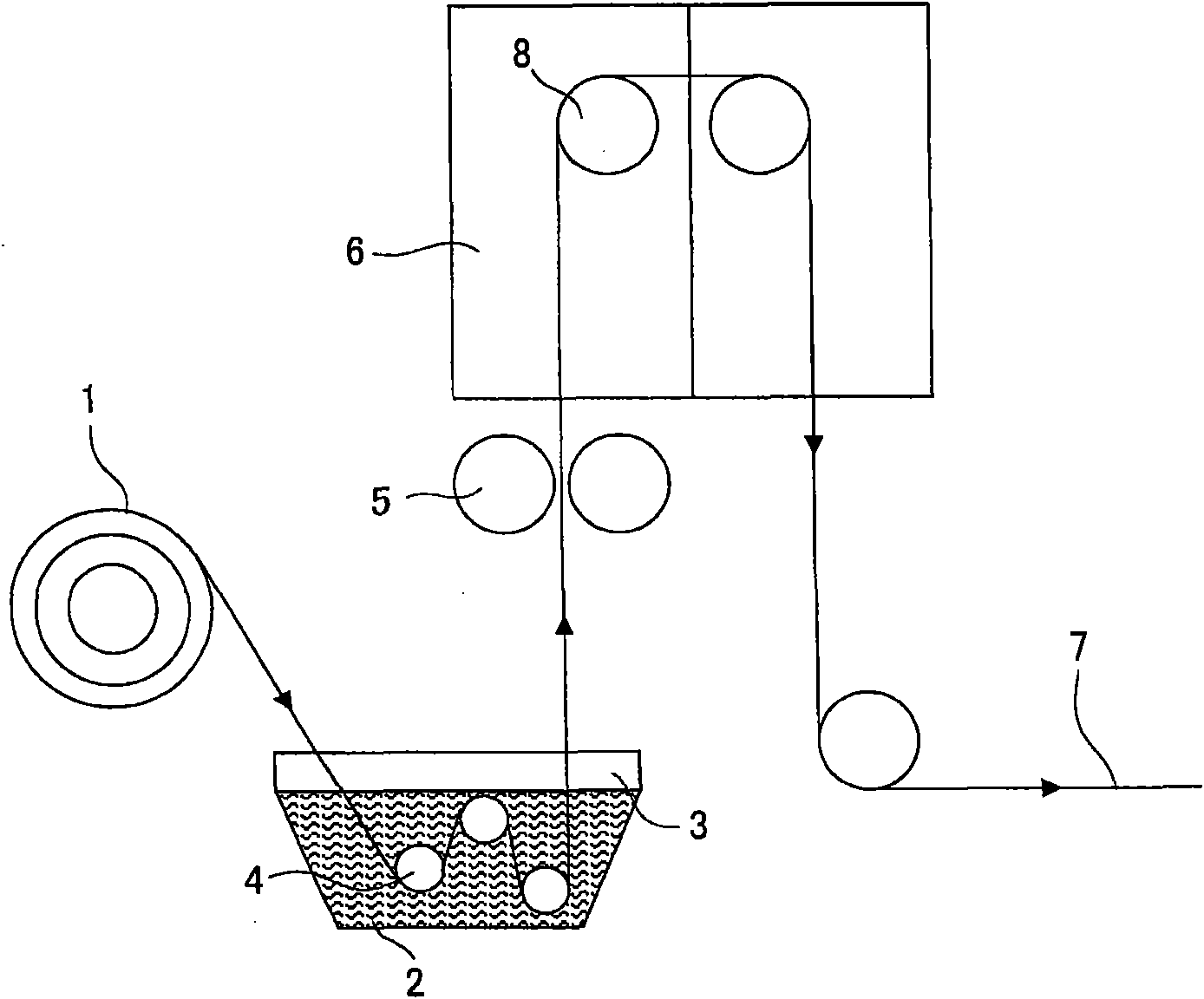

[0170] (1) Preparation of resin varnish containing epoxy resin composition

[0171] First, 9.950 wt % of silica nanoparticles (average particle diameter 56 nm) and 54.725 wt % of particle A (silica, SO25R, average particle diameter 0.5 μm, manufactured by Admatechs Co., Ltd.) were dispersed in dimethyl ethyl ether Amide, MEK (the ratio of the two is dimethylacetamide: MEK = 1: 3), and the concentration of the inorganic filler (silica nanoparticles and silica particles) prepared is 60% by weight of the inorganic filler slurry . Next, dissolve solid epoxy resin A (NC3000, biphenyl aralkyl type epoxy resin, weight average molecular weight 1300, softening point 57 ℃, epoxy equivalent 276g / eq, Nippon Kayaku ( Co., Ltd.) 9.800% by weight, cyanate resin A (PT30, novolac type cyanate resin, weight average molecular weight 380, manufactured by Lonza Japan Ltd.) 17.500% by weight, phenolic resin A (MEH7851, Meiwa Chemical Industry Co., Ltd.) 7.700% by weight and epoxy silane coupling ...

Embodiment 2

[0188] Except having adjusted the resin varnish component containing an epoxy resin composition as follows, it carried out similarly to Example 1. That is, solid epoxy resin A is 8.400% by weight, cyanate resin A is 15.000% by weight, phenolic resin A is 6.600% by weight, silica nanoparticles are 9.950% by weight, particle B (silicon dioxide, SO32R, average particle diameter 1.1 μm, manufactured by Admatechs Co., Ltd.) was 59.700% by weight, and the epoxysilane coupling agent was 0.350% by weight.

Embodiment 3

[0190] Except having adjusted the resin varnish component containing an epoxy resin composition as follows, it carried out similarly to Example 1. That is, solid epoxy resin B (EXA7320, naphthalene type, weight average molecular weight 750, softening point 58° C., epoxy equivalent 250 g / eq, manufactured by Dainippon Ink Chemical Industry Co., Ltd.) is 13.860% by weight, and cyanate resin A is 13.860% by weight, 9.950% by weight of silica nanoparticles, 61.690% by weight of particle A, curing catalyst A (キユアゾ-ル 2P4MHZ, 2-phenyl-4-methyl-5-hydroxymethylimidazole, Shikoku Chemical Industry Co., Ltd.) was 0.280% by weight, and the epoxysilane coupling agent was 0.360% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com