A kind of tea greening machine drum

A degreening machine and drum technology, applied in tea treatment before extraction, etc., can solve problems affecting tea quality, poor uniformity of fresh leaves degreening, affecting tea quality, etc., to improve tea quality and processing benefits, good dehydration effect, Good dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

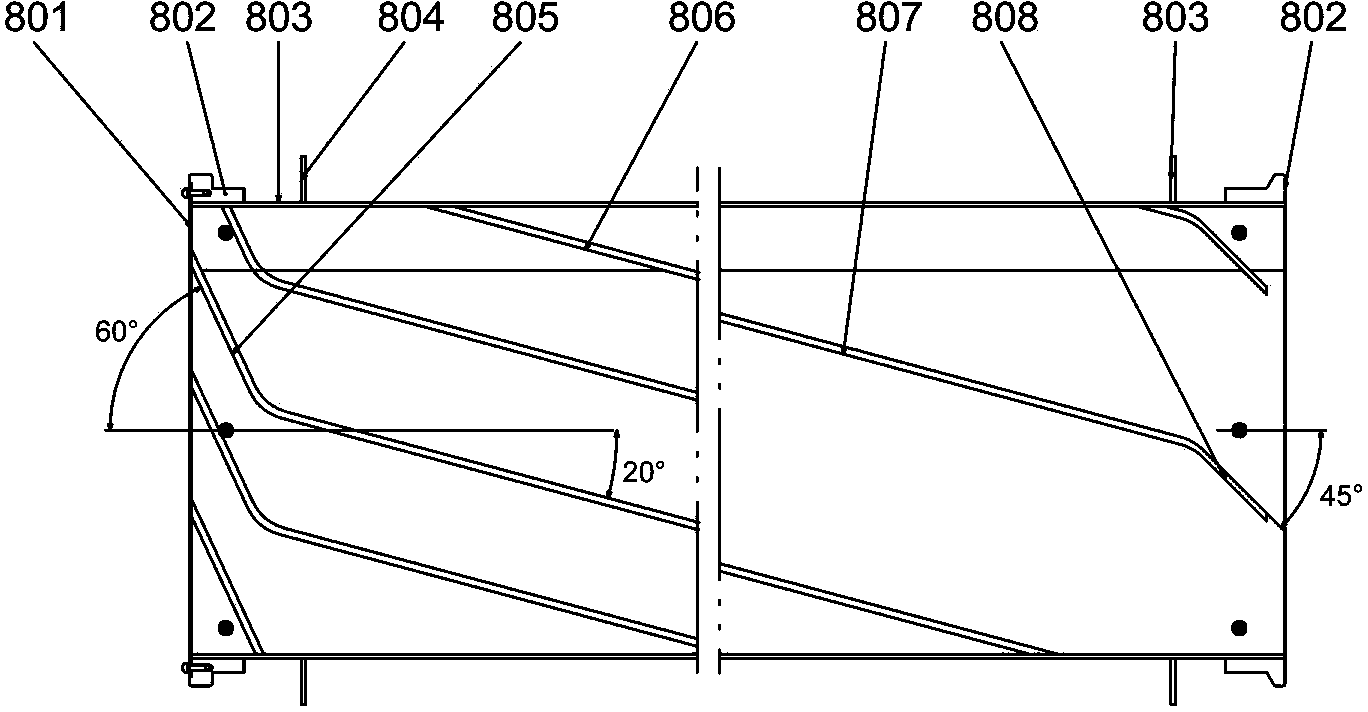

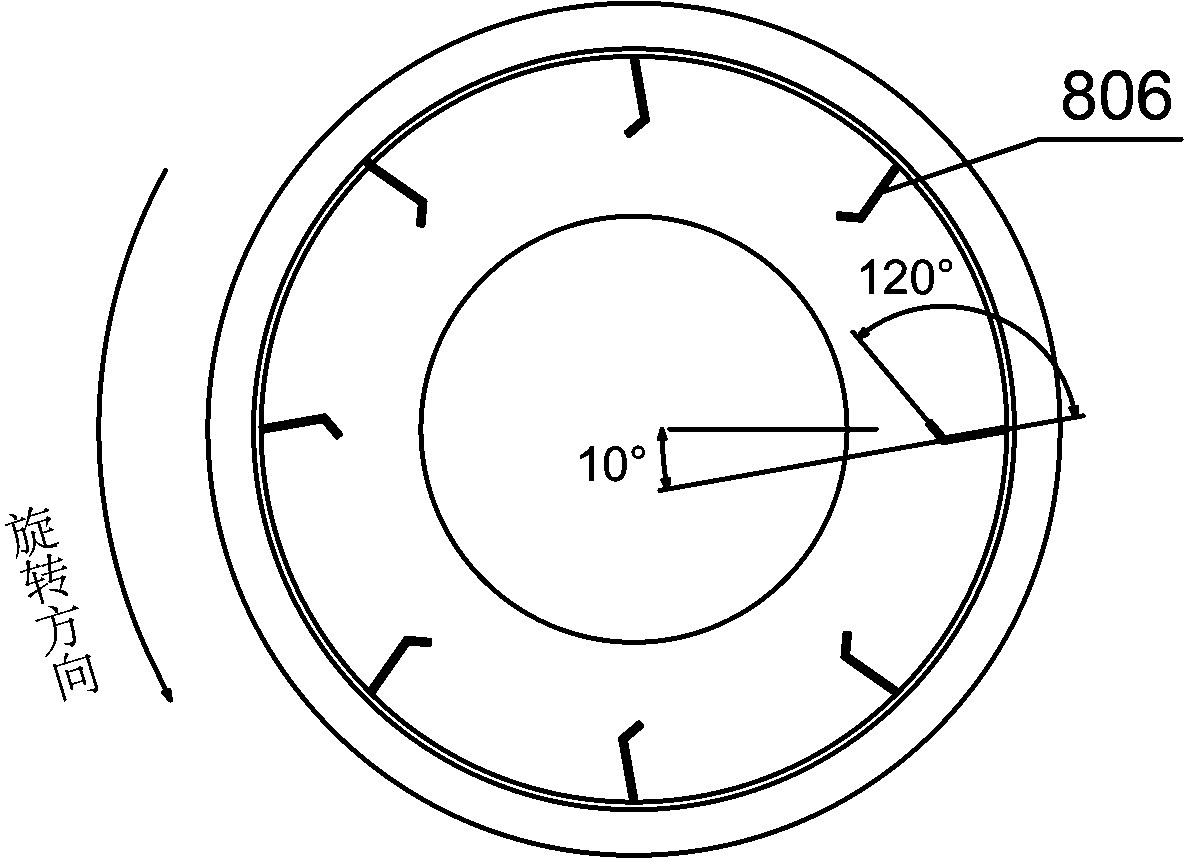

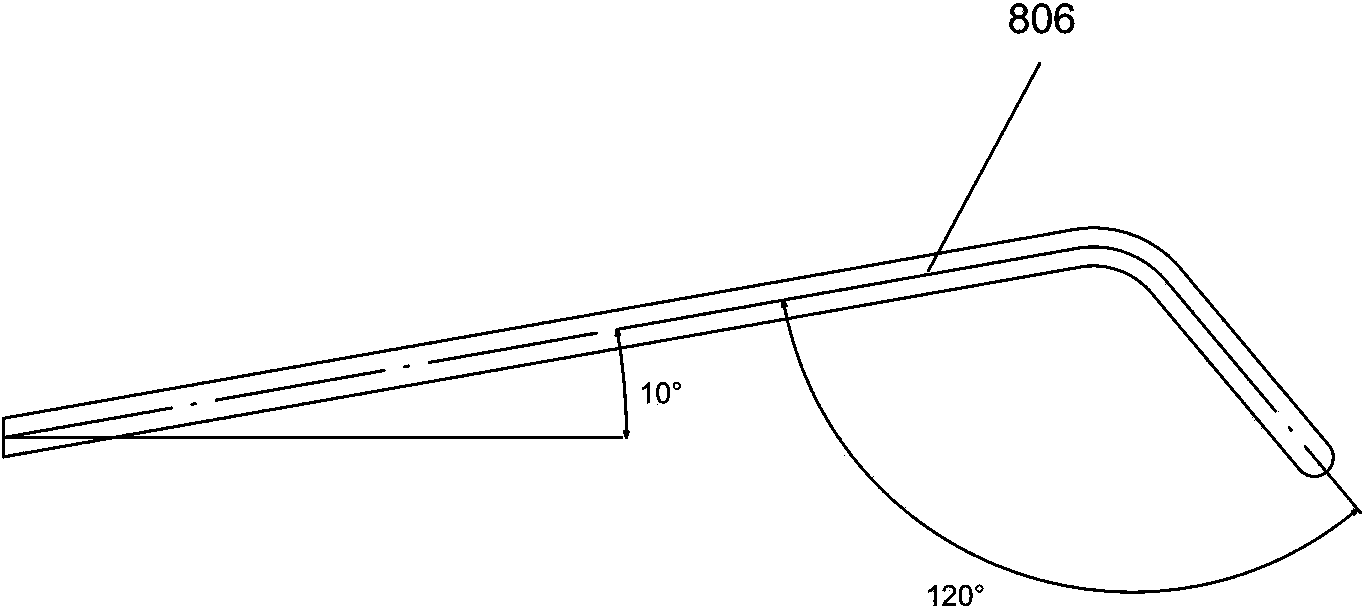

[0023] See attached Figure 1~4 , a drum of a tea greening machine according to the present invention, comprising a cylinder body 803, a ventilating disc 801 is installed at the bottom of the cylinder body 803, a rolling ring 802 and a smoke retaining ring 804 are installed on the outer wall, and guide vanes are installed on the inner wall, and the guide vanes The plate includes a feed end guide vane plate 805 arranged at the feed end of the cylinder body 803 and a discharge end guide vane plate 808 arranged at the discharge end of the cylinder body 803, and the rear part of the feed end guide vane plate 805 is connected to the front guide vane plate 806 , the front part of the discharge end guide vane 808 is connected to the rear guide vane 807, the number of the front guide vane 806 is 8, the rear guide vane is 5, and the number of the front guide vane 806 is more than that of the rear guide vane 807 Three pieces, suitable number of guide vanes can be installed according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com