All-position automatic welding system

An automatic welding and all-position technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of long construction period and low construction efficiency, achieve high welding quality, ensure real-time performance, and save data processing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

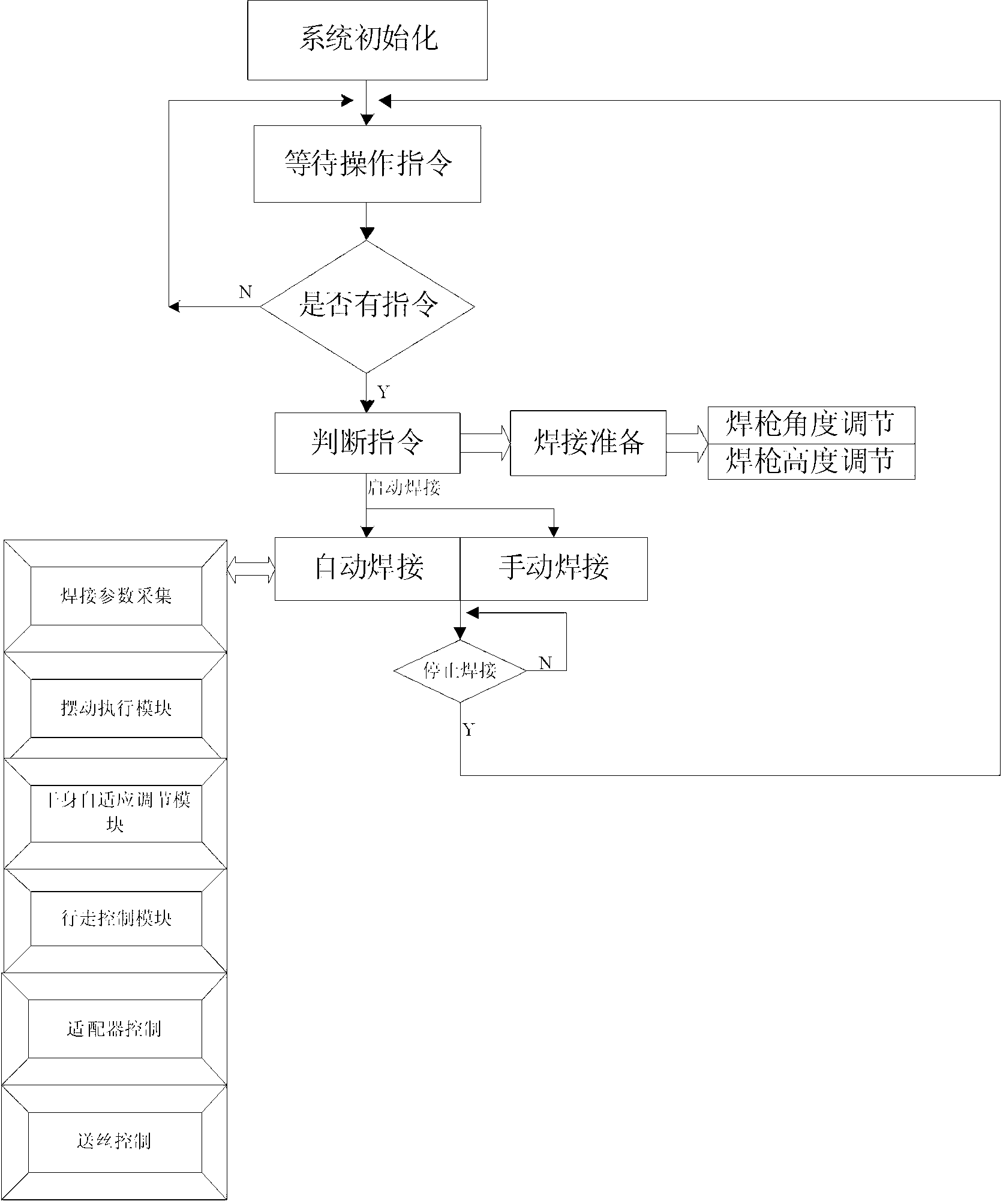

[0013] The best embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

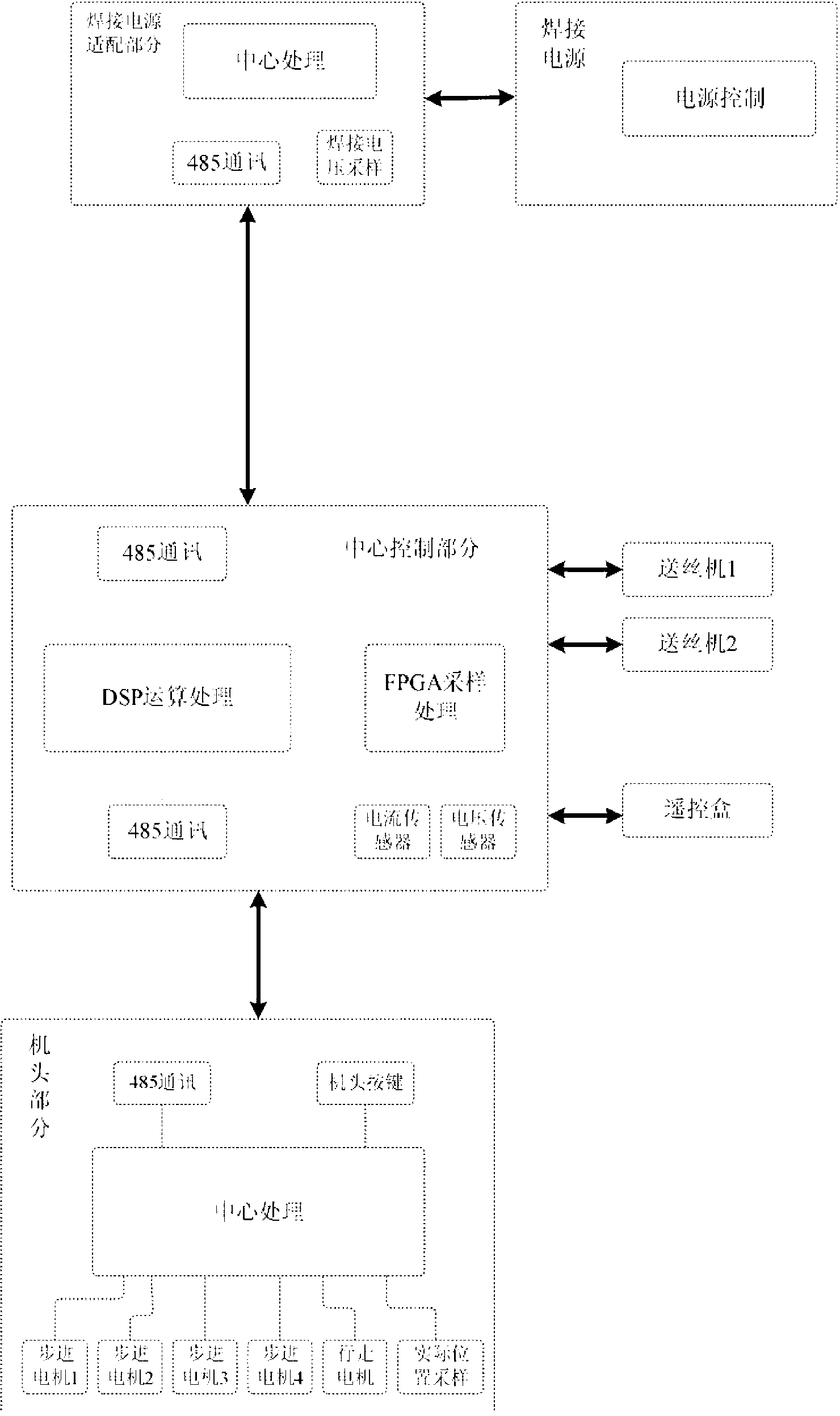

[0014] Such as figure 1 As shown, the all-position automatic welding system mainly includes a welding head module, a central controller, a welding power supply module, a power adapter, and a remote control operation module. The welding head module sends the current position information of the welding torch to the central controller, The central controller performs calculation and processing on the data. The central controller gives corresponding welding instructions according to the results of the current position calculation and processing. The power adapter controls the output of the welding power supply according to the welding instructions of the central controller. The torch movement realizes the real-time control of the seam tracking process.

[0015] The welding head module is used to execute welding commands, control welding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com