Semi-automatic plate-feeding machine

A board feeding machine and semi-automatic technology, applied in the direction of lamination device, object supply, pile separation, etc., can solve the problems of large investment in fixed assets, dislocation of surface layers, large installation area, etc., to improve the internal quality and appearance The effect of high quality, reduced production and operation costs, and small installation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

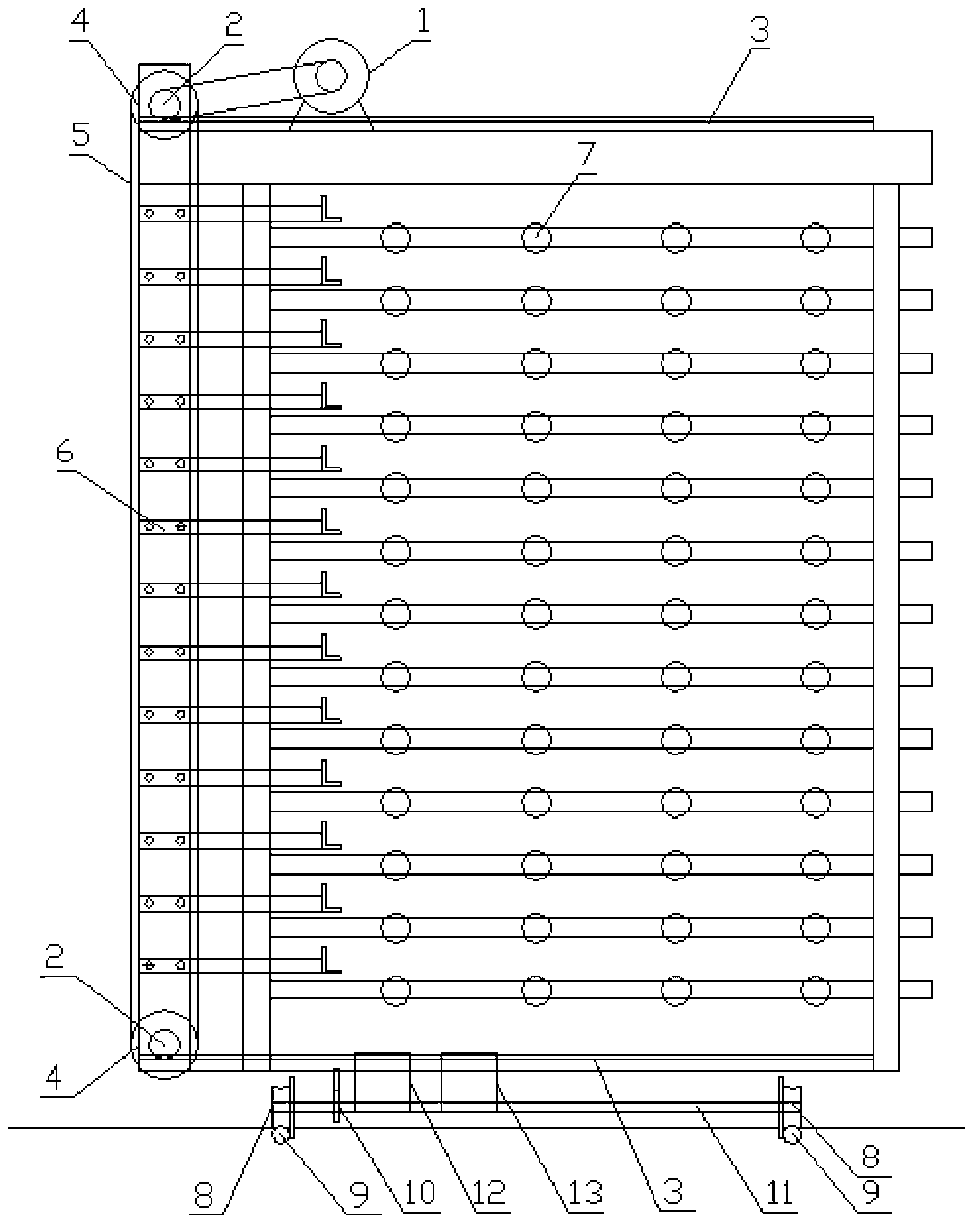

[0016] Such as figure 1 , the semi-automatic board feeder 4 includes the board feeder frequency conversion speed regulation motor 1, the transmission gear 2, the sprocket 4, the chain 5, the push board mechanism 6 and the roller 7, and the semi-automatic board feeder 4 is provided with multiple rows of rollers 7, each row of rollers The outer side of 7 is provided with a corresponding push plate mechanism 6, and a plurality of said push plate mechanisms 6 are arranged on the chain 5, and a sprocket 4 is respectively provided at the upper and lower ends of the chain 5, and the sprocket 4 is connected to the board frequency conversion through the transmission gear 2. Speed motor 1.

[0017] The upper and lower sides of the semi-automatic plate feeder 4 are also provided with a tooth bar 3 connecting the transmission gear 2 .

[0018] The bottom of the semi-automatic plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com