Detergent and preparation method thereof

A detergent and soap-based technology, applied in the field of detergent and its preparation, can solve the problems of detergent residue, high consumption, increased cleaning dirt and oil cost, etc. good effect strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

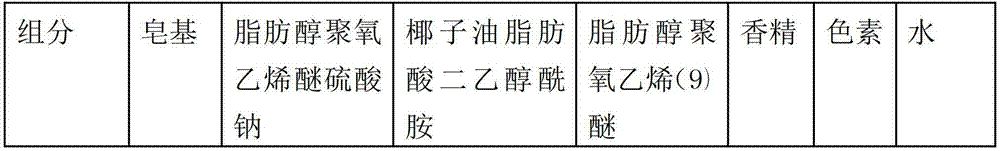

[0031] The components of detergent and the weight percentage of each component are: (total weight: 1kg)

[0032]

[0033]

[0034] Among them, the composition of the soap base and the weight percentage of each component are: (total weight: 1Kg)

[0035] components

alkali

Absolute ethanol

water

Weight (g)

220

145

280

355

Weight percentage (%)

22

14.5

28

35.5

[0036] Wherein, the oil can be animal oil or vegetable oil; the alkali can be commonly used alkalis such as sodium hydroxide, potassium hydroxide, and sodium carbonate. Soap base also can be the soap base of prior art in the market.

[0037] The preparation method of dish soap is:

[0038] a, the components of the above-mentioned detergent are mixed in the above ratio;

[0039] b. Stir and heat to 82°C, wherein the stirring speed is 275r / min;

[0040] c. After cooling, the finished detergent essence is obtained.

[0041] Where...

Embodiment 2

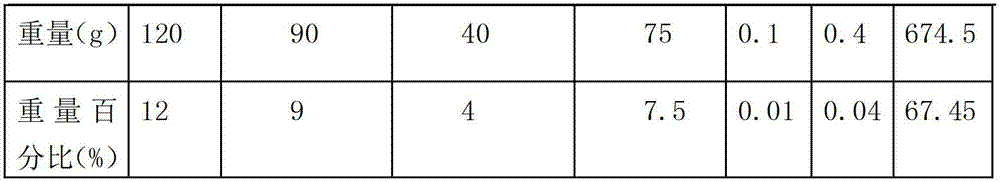

[0048] The components of detergent and the weight percentage of each component are: (total weight: 1kg)

[0049]

[0050]

[0051] Among them, the composition of the soap base and the weight percentage of each component are: (total weight: 1Kg)

[0052] components

alkali

Absolute ethanol

water

Weight (g)

230

140

300

330

Weight percentage (%)

23

14

30

33

[0053] Wherein, the grease is the product of waste edible oil purification treatment; the alkali can be common alkali such as sodium hydroxide, potassium hydroxide, sodium carbonate.

[0054] The preparation method of dish soap is:

[0055]a, the components of the above-mentioned detergent are mixed in the above ratio;

[0056] b. Stir and heat to 80°C, wherein the stirring speed is 295r / min;

[0057] c. After cooling, the finished detergent essence is obtained.

[0058] Wherein, the preparation method of soap base is:

[0059] a....

Embodiment 3

[0066] The components of detergent and the weight percentage of each component are: (total weight: 1kg)

[0067]

[0068] Among them, the composition of the soap base and the weight percentage of each component are: (total weight: 1Kg)

[0069] components

grease

alkali

Absolute ethanol

water

Weight (g)

250

125

250

375

Weight percentage (%)

25

12.5

25

37.5

[0070] Wherein, the grease is the product of waste edible oil purification treatment; the alkali can be common alkali such as sodium hydroxide, potassium hydroxide, sodium carbonate.

[0071] The preparation method of dish soap is:

[0072] a, the components of the above-mentioned detergent are mixed in the above ratio;

[0073] b. Stir and heat to 81°C, wherein the stirring speed is 275r / min;

[0074] c. After cooling, the finished detergent essence is obtained.

[0075] Wherein, the preparation method of soap base is:

[0076] a. Mix oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com