Calibration method and device for a gis partial discharge ultrasonic detection device

A technology of ultrasonic detection and partial discharge, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve problems such as unsatisfactory repeatability, achieve ideal repeatability, good calibration repeatability, and avoid human factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

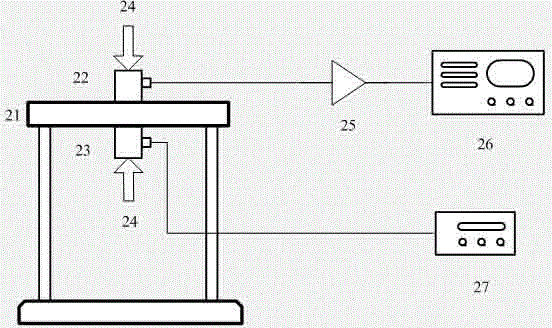

[0033] The calibration method of the GIS partial discharge ultrasonic detection device of the present invention comprises the following steps:

[0034] In S1, the acoustic emission transducer and the primary calibrated reference sensor are respectively placed at the center of the upper and lower surfaces of a calibration table with a circular aluminum table top. The diameter-thickness ratio of the aluminum table top should be greater than 20, and the surface finish should not be low. At Ra3.2, the reference ultrasonic sensor is connected to the partial discharge ultrasonic detector after the preamplifier, and the transmitting transducer is connected to the pulse signal source;

[0035] S2 Load the coupling force of not less than 10N on the reference sensor and the acoustic emission transducer respectively, and empty the air bubbles between the reference sensor and the acoustic emission transducer and the platform table;

[0036] The S3 pulse voltage source generates a pulse vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com