Detection and maintenance method for self-aligning roller bearing of spindle of wind driven generator and jacking tool

A wind turbine, automatic centering technology, applied in the direction of mechanical bearing testing, wind power generation, manufacturing motor generators, etc., can solve the problem of temperature rise of 670 bearings, hoisting and transportation costs and negative effects, return of wind turbine owners, etc. problem, to achieve the effect of avoiding the risk of lifting, improving the reputation and avoiding the risk of return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

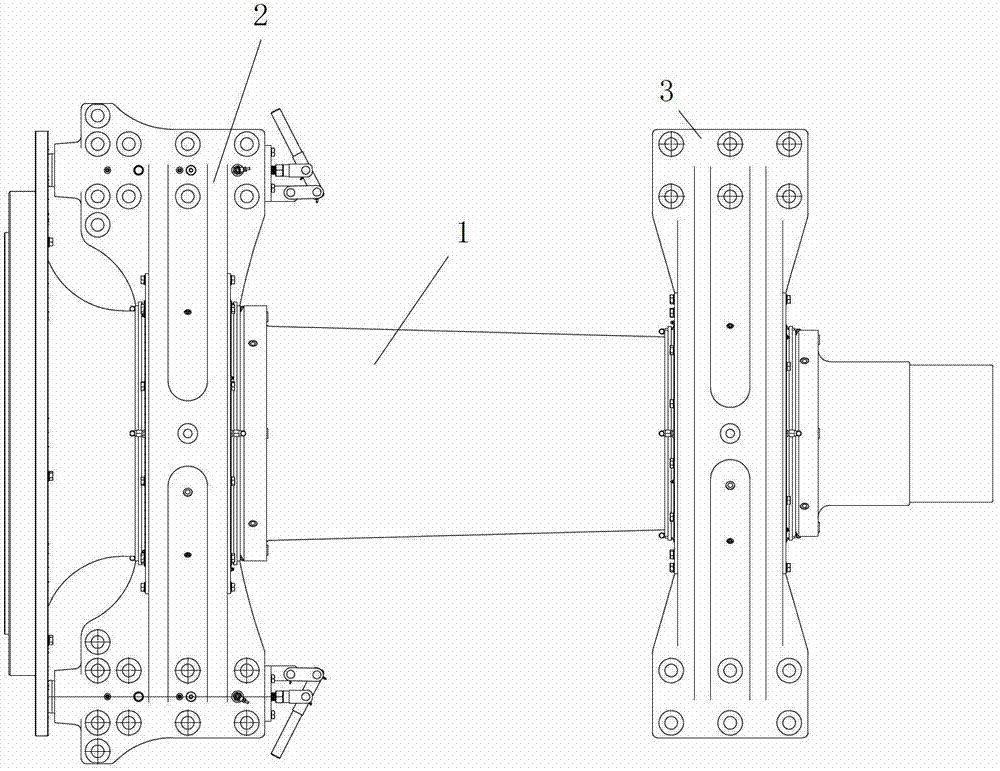

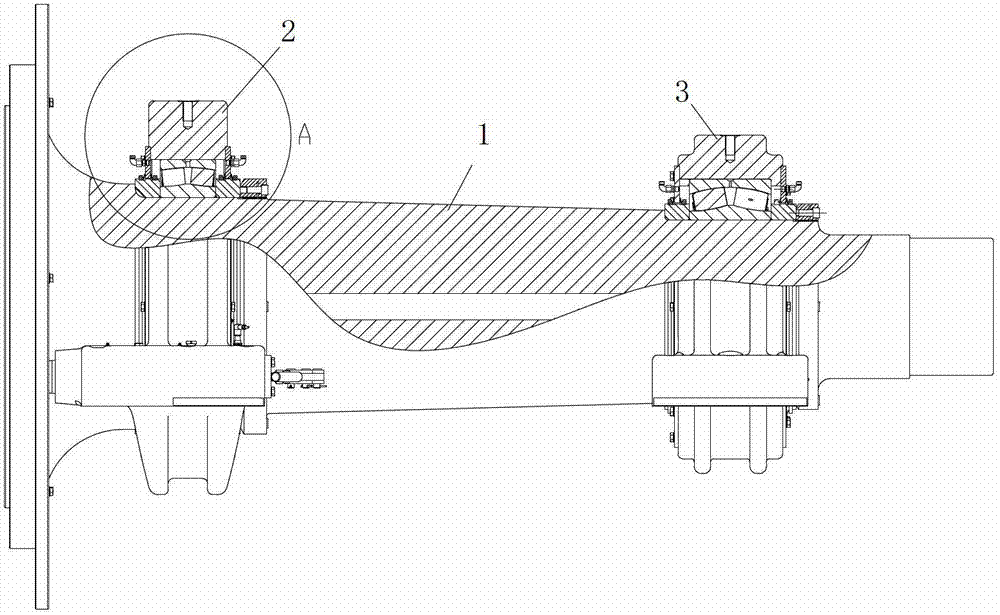

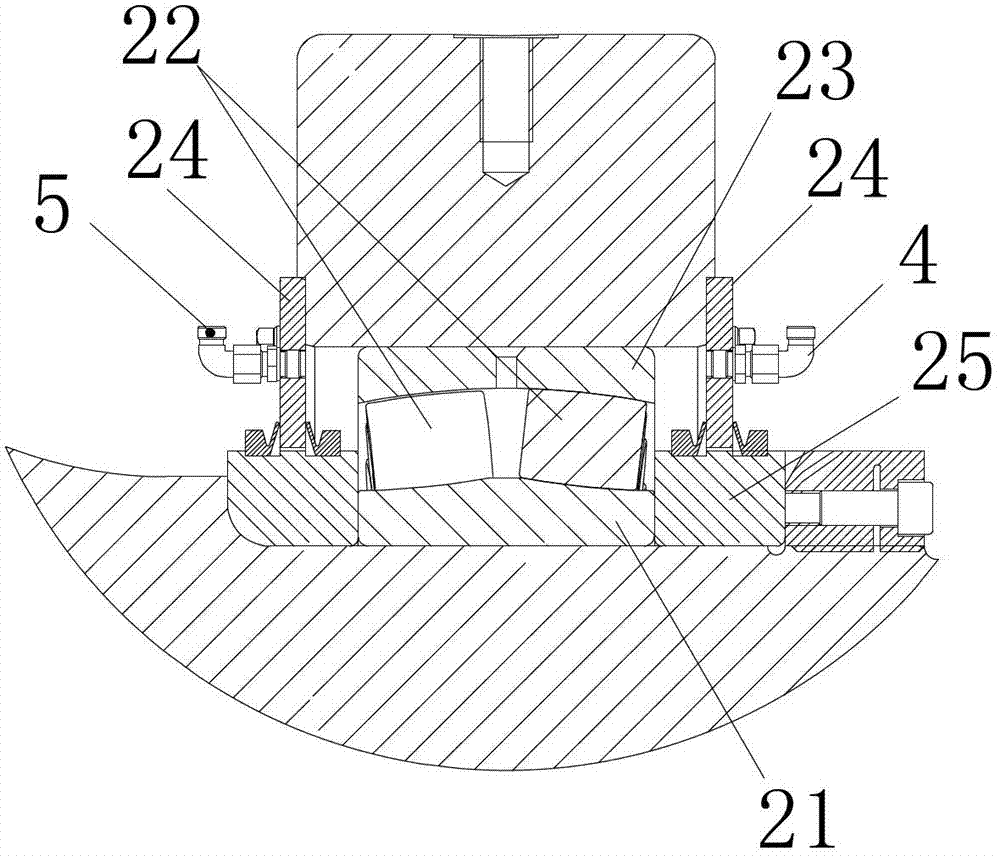

[0039] Such as figure 1 with figure 2As shown, the wind turbine main shaft 1 is equipped with a 670 bearing 2 on the side close to the hub, and the fan main shaft 1 is also equipped with another self-aligning roller bearing 3 (hereinafter referred to as the 530 bearing). In view of the characteristics of the 670 bearing, the present invention discloses a wind turbine main shaft The automatic self-aligning roller bearing detection and maintenance method includes the following steps:

[0040] Step 1 Open the end cover of the automatic self-aligning roller bearing to clean the grease

[0041] Open the left end cover, select four points on the end surface of the outer ring at 3 o'clock, 6 o'clock, 9 o'clock and 12 o'clock, and clean the lubricating grease at the four o'clock positions on the left end surface of the outer ring. In the oil receiving box, the end faces of the outer ring in the above four positions are exposed;

[0042] Step 2 Detect the axial position of the oute...

Embodiment 1

[0052] Example 1: Adjustment of 5# fan in Langergou wind field in Dingbian, Shaanxi

[0053] On August 28, 2012, we arrived at the Langergou Wind Farm and adjusted the 5# unit. The results before and after the adjustment are as follows: The fan is running well after adjustment.

[0054] project

Embodiment 2

[0055] Example 2: Adjustment results of 8# fan in Wujiangyuan wind field, Guizhou

[0056] Wujiangyuan 8# unit has been inspected, and the size from the end face of the bearing outer ring to the end cover installation surface is 33mm. Like the Heijiayi 24# fan, the temperature is as high as 62 degrees when it is fully blown, and it often shuts down, so it has to limit the speed to 1200RPM. On September 14, 2012, the technical department, together with the quality department, and relevant personnel from the Zhongshan Base, we arrived at the Wujiangyuan wind farm to adjust the machine, and the results are as follows

[0057] project

670 bearing temperature before adjustment

62 degrees

Adjusted 670 bearing temperature

40 degree

[0058] Dimensions after adjustment from the outer ring of the bearing to the mounting surface of the end cover

30.1

Bearing Grease Condition

good

No

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com