Sulphur condensing and separating deice of sulphur recovering device

A technology of sulfur recovery and separation equipment, which is applied in the direction of sulfur preparation/purification, which can solve problems such as soil pollution, air pollution, and damage, and achieve the effects of reducing environmental and soil pollution, reducing pollution, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

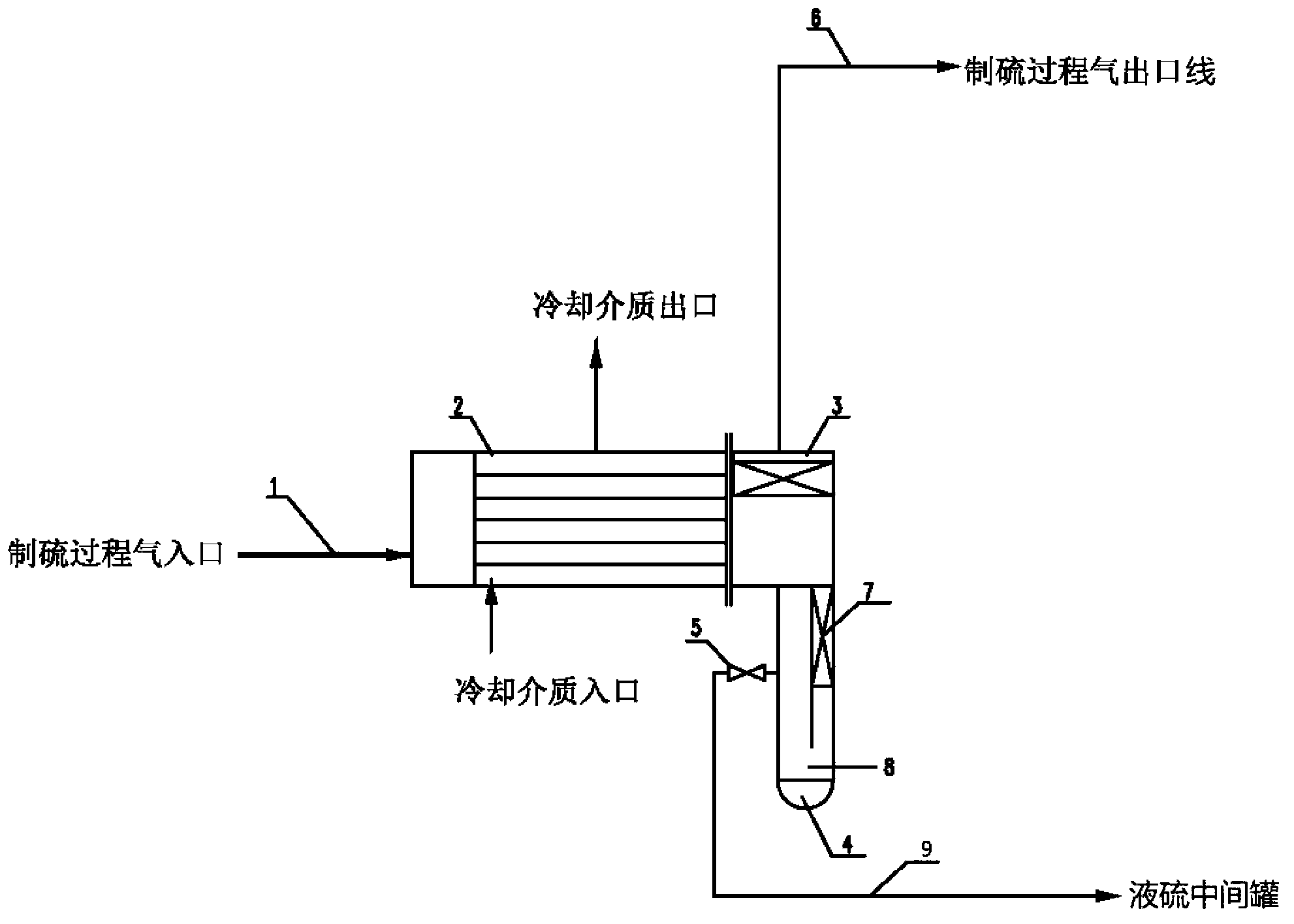

[0024] Such as figure 1 The sulfur condensation and separation equipment of the sulfur recovery unit shown includes a process gas condensation cooler 2 and a liquid sulfur separator 4. The liquid sulfur separator 4 is located below the head of the process gas condensation cooler 2. The head and liquid sulfur separator Steam heating facilities are arranged outside the sulfur separator 4. The liquid sulfur separator 4 is composed of a packing layer section 7 and a liquid sulfur collection section 8. The liquid sulfur separator 4 is provided with a liquid sulfur outlet, which is controlled by the liquid sulfur outlet valve 5. The sulfur outlet line 9 is connected to the liquid sulfur intermediate tank, and the liquid sulfur intermediate tank is connected to the liquid sulfur storage tank; the process gas outlet is provided with a liquid sulfur trap 3, and the process gas outlet is connected to the sulfur production process gas outlet line 6, and the sulfur production process gas o...

Embodiment 2

[0028] Such as figure 1 The sulfur condensation and separation equipment of the sulfur recovery unit shown includes a process gas condensation cooler 2 and a liquid sulfur separator 4. The liquid sulfur separator 4 is located below the head 2 of the process gas condensation cooler. The head and liquid sulfur Steam heating facilities are arranged outside the separator 4. The liquid sulfur separator 4 is composed of a packing layer section 7 and a liquid sulfur collection section 8. The liquid sulfur separator 4 is provided with a liquid sulfur outlet, which is controlled by the liquid sulfur outlet valve 5. The outlet line 9 is connected to the liquid sulfur intermediate tank, and the liquid sulfur intermediate tank is connected to the liquid sulfur storage tank; the process gas outlet is provided with a liquid sulfur trap 3, the process gas outlet is connected to the sulfur production process gas outlet line 6, and the sulfur production process gas outlet line 6 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com