Production method of water-soluble phenolic resin cross-linking agent used for water shut-off and profile control of oil field

A technology of water-soluble phenolic resin and production method, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve the problems of reduced activity of crosslinking agents, high content of tertiary hydroxyphenols and quaternary hydroxyphenols, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

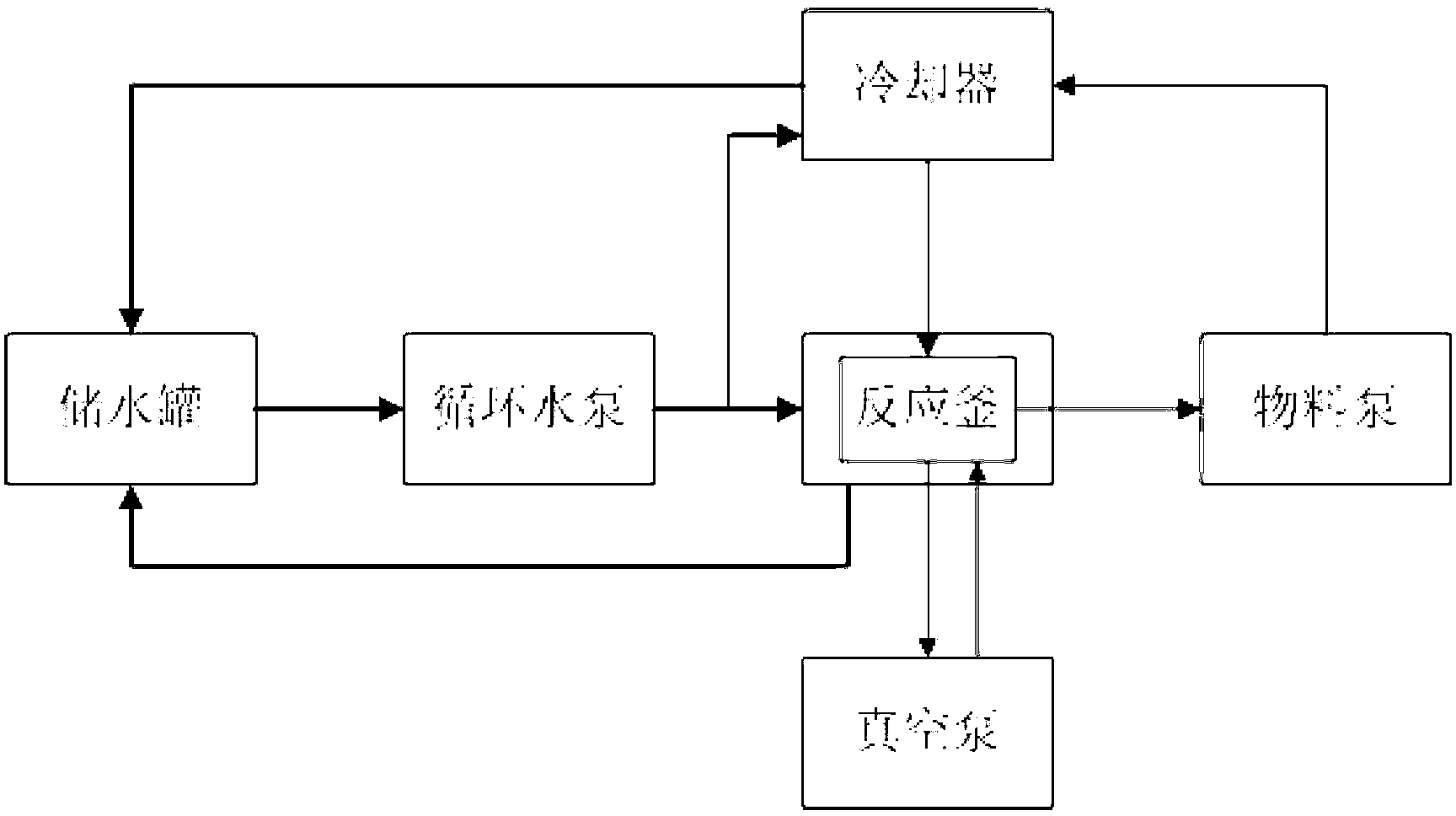

Method used

Image

Examples

Embodiment 1

[0034] Add 680kg of formaldehyde, 300kg of phenol, and 18kg of sodium hydroxide into the reactor to prepare according to the above-mentioned production process, and the temperature of the circulating cooling water is 25°C. (2.12~2.57): 1

Embodiment 2

[0036] Add 690kg of formaldehyde, 290kg of phenol, and 19kg of sodium hydroxide into the reactor to prepare according to the above-mentioned production process, and the temperature of the circulating cooling water is 10°C.

[0037] Composition analysis of water-soluble phenolic resin crosslinking agent (Table 1):

[0038]

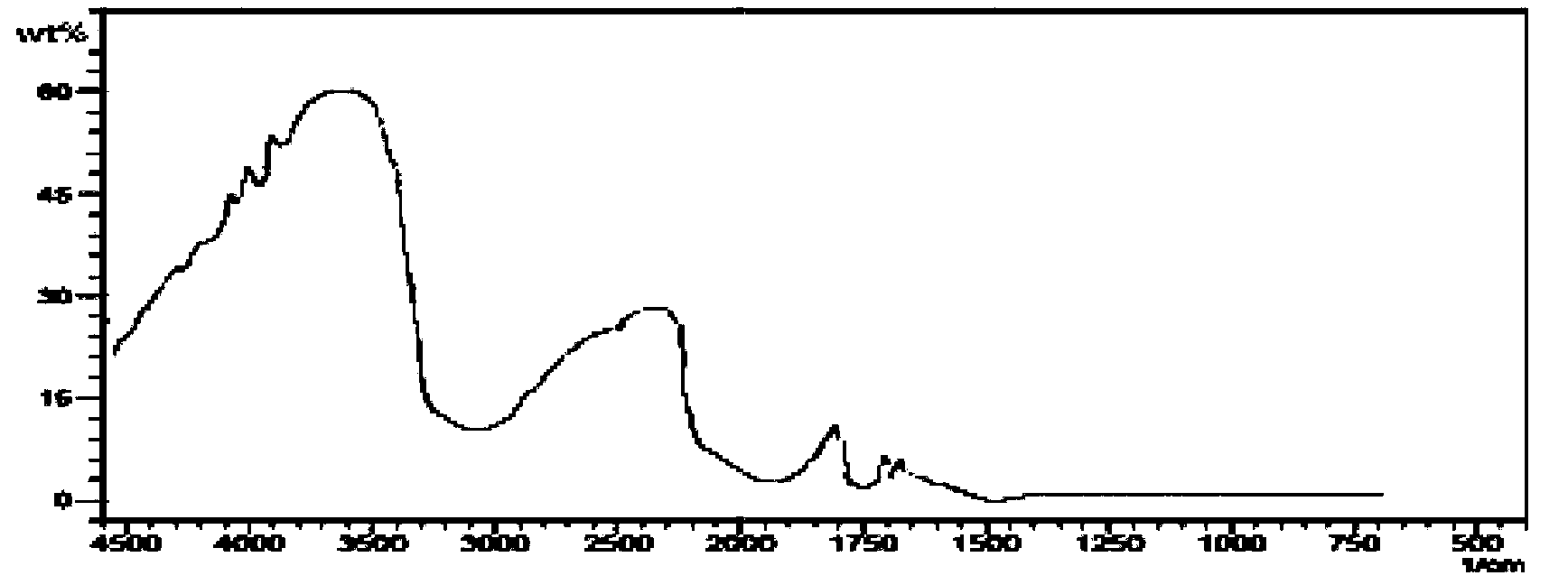

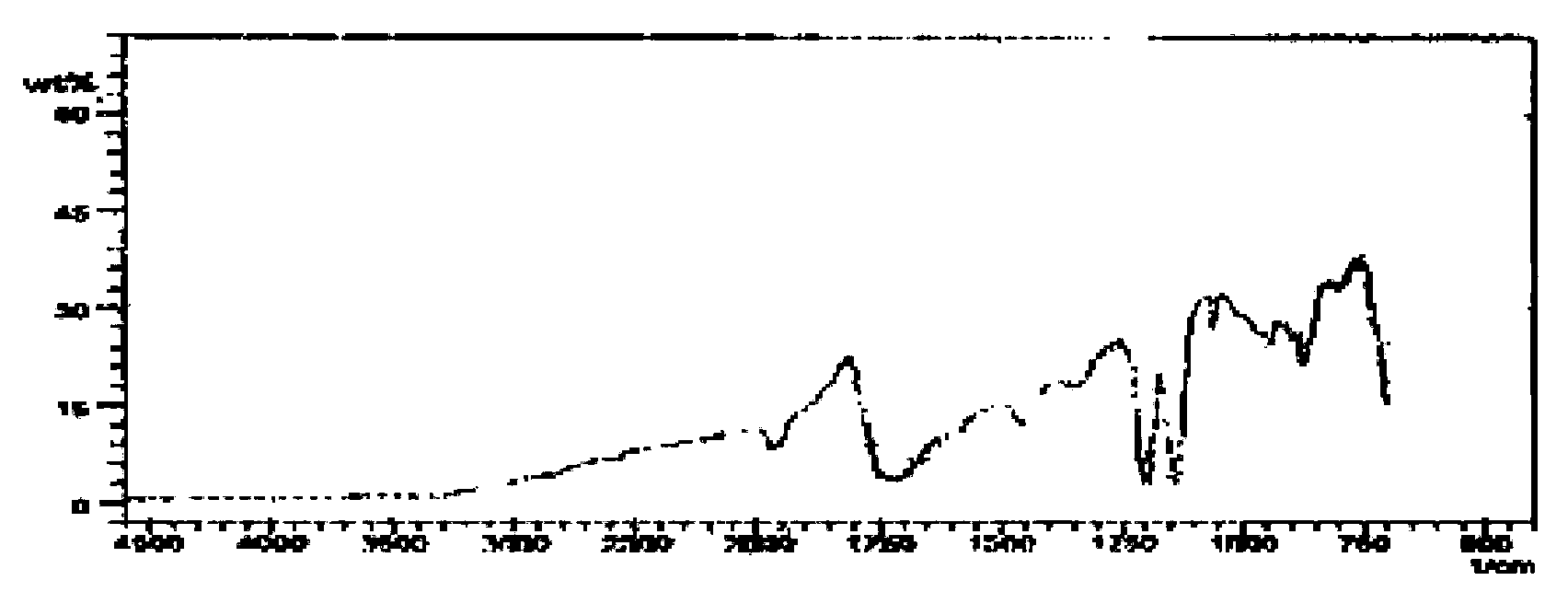

[0039] Cooperate with infrared spectrometer, ultraviolet spectrometer and chromatographic instrument to carry out qualitative and quantitative analysis on the product components, and fit the qualitative and quantitative detection data to the obtained curve as follows: figure 1 , figure 2 shown.

Embodiment 3

[0041] Add 680kg of formaldehyde, 320kg of phenol, and 20kg of sodium hydroxide into the reactor to prepare according to the above-mentioned production process, and the temperature of the circulating cooling water is 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com