Non-crosslinked polypropylene resin pre-expanded particles and in-mold foamed moldings

A cross-linked polypropylene and pre-foaming technology, which is applied in the field of in-mold foaming moldings, can solve problems such as undetermined effects and unexpectable effects, and achieve the effects of excellent weldability, excellent antistatic properties, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

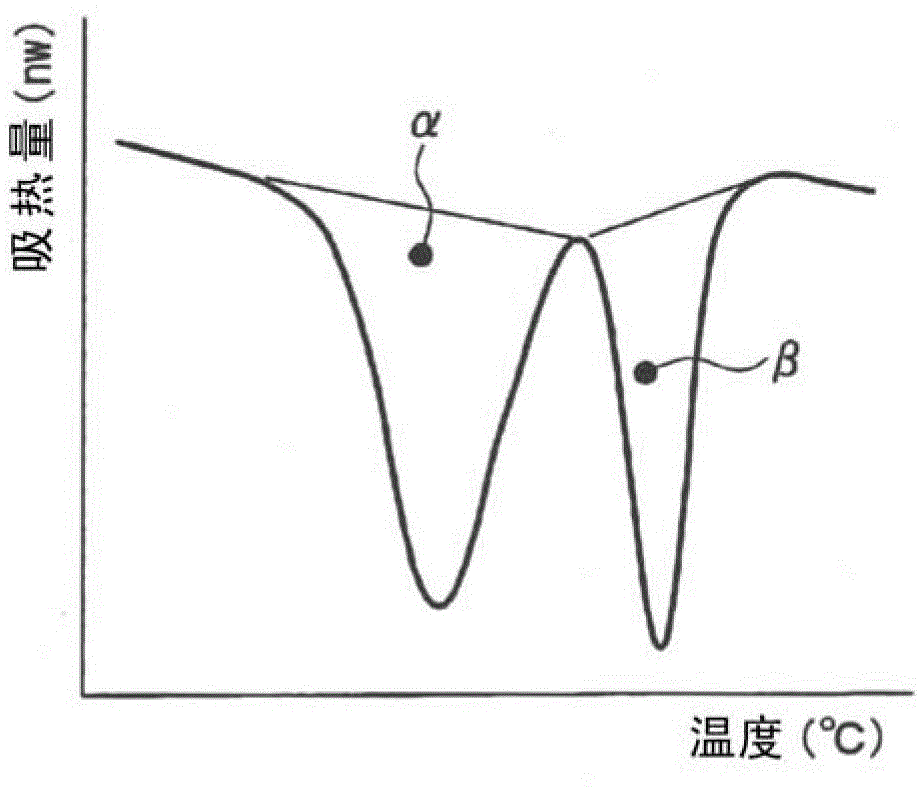

Image

Examples

Embodiment

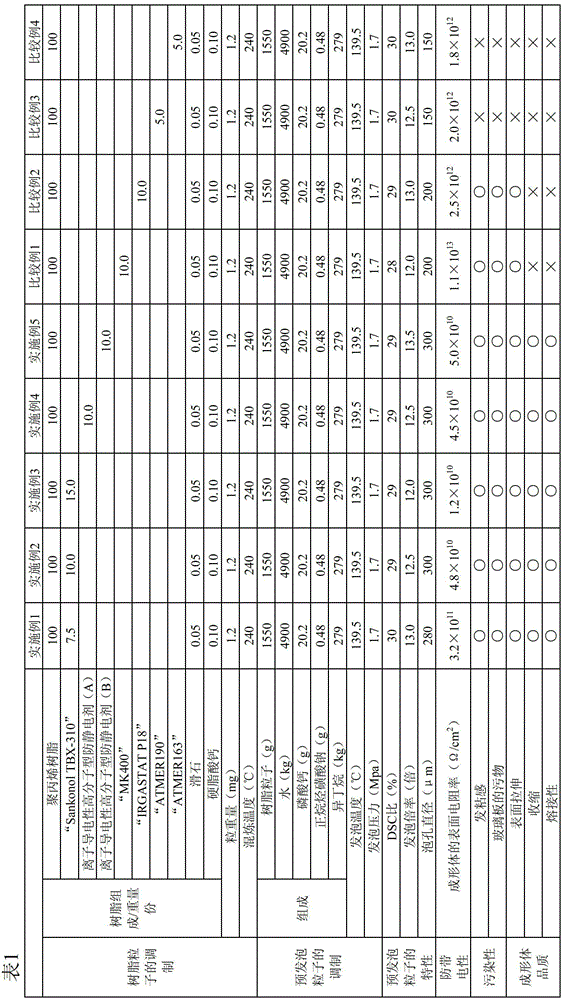

[0069] Hereinafter, the present invention will be explained in more detail based on examples, but the present invention is not limited to these.

[0070]

[0071] Using a "Hirester MCP" tester manufactured by Mitsubishi Chemical Corporation, a voltage of 500V was applied to the surface of a molded body of 400×300×50mm for 1 minute, a measurement temperature of 23°C, and a humidity of 50%RH under the conditions of an atmosphere, according to JIS K6911 measures the surface resistivity. The lower the surface resistivity value, the higher the antistatic property.

[0072]

[0073] The molded body was directly touched by hand for evaluation. A sample with a sticky feeling is marked as ×, and a sample without sticky feeling is marked as ○. In addition, a glass plate of 100×100×1 mm was covered on the surface of the molded body, and after heat treatment in an oven at 80° C. for 1 week, it was restored to room temperature, and the dirt adhering to the glass plate was judged. The sample ...

manufacture example 1

[0092] After mixing a mixture of 90 parts by weight of polyether / polyolefin block copolymer ("Pelestat 300" manufactured by Sanyo Chemical Industry Co., Ltd.) and 10 parts by weight of lithium bis(trifluoromethanesulfonyl)imide with a Henschel mixer, It was put into a twin-screw extruder, kneaded and extruded while heating at a temperature of 200°C, and then pelletized after water cooling to obtain an ion conductive polymer type antistatic agent (A).

manufacture example 2

[0094] In Production Example 1, except for changing the lithium bis(trifluoromethanesulfonyl)imide to lithium trifluoromethanesulfonate, the ion conductive polymer type antistatic agent (B) was obtained by the same method as in Production Example 1. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com