Chroma-adjustable caramel pigment producing process

A production process, technology of caramel pigment, applied in the direction of azo dyes, organic dyes, chemical instruments and methods, etc., can solve the problems of complex production equipment of caramel pigment, low red index, poor stability of caramel pigment, etc., and achieve expansion The effect of product coverage, high red index, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

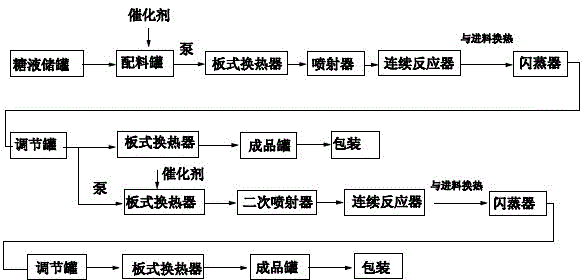

Method used

Image

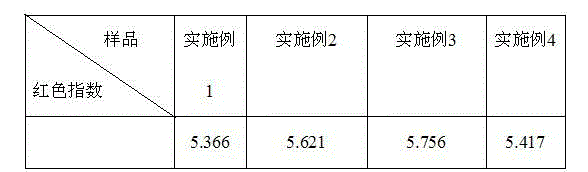

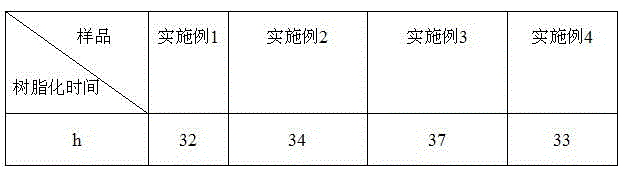

Examples

Embodiment 1

[0050] (1) For ingredients, put glucose or F55 fructose with a concentration of 75% from the syrup storage tank into the ingredient tank, and then add ammonia water with a mass concentration of 25% through the metering tank. Note that the ammonia water pipe should be inserted into the bottom of the ingredient tank, and the addition ratio is according to Add concentrated ammonia water to 1% of the dry base of the syrup, and keep stirring. The process of adding ammonia water should be slow and uniform. Adjust the pH of the batching tank to 10-10.5, and the temperature will rise by 5-8°C (if there is a lot of foam, add a small amount of defoamer if necessary).

[0051] (2) Heat exchange. After the batching is completed, the materials are pumped into the plate heat exchanger to exchange heat with the high-temperature materials that have been reacted once to heat up the materials.

[0052] (3) Once sprayed, the material after heat exchange is instantly mixed with steam through the i...

Embodiment 2

[0057] (1) For ingredients, put glucose or F55 fructose with a concentration of 77% into the ingredient tank from the syrup storage tank, and then add ammonia water with a mass concentration of 25% through the metering tank. Note that the ammonia water pipe should be inserted into the bottom of the ingredient tank, and the addition ratio is according to Add concentrated ammonia water to 4% of the dry base of the syrup, and keep stirring. The process of adding ammonia water should be slow and uniform. Adjust the pH of the batching tank to 10-10.5, and the temperature will rise by 5-8°C (if there is a lot of foam, add a small amount of defoamer if necessary).

[0058] (2) Heat exchange. After the batching is completed, the materials are pumped into the plate heat exchanger to exchange heat with the high-temperature materials that have been reacted once to heat up the materials.

[0059] (3) Once sprayed, the material after heat exchange is instantly mixed with steam through the inj...

Embodiment 3

[0064] (1) For ingredients, put glucose or F55 fructose with a concentration of 76% into the ingredient tank from the syrup storage tank, and then add ammonia water with a mass concentration of 25% through the metering tank. Note that the ammonia water pipe should be inserted into the bottom of the ingredient tank, and the addition ratio is according to Add concentrated ammonia water to 3% of the dry base of the syrup, and keep stirring. The process of adding ammonia water should be slow and uniform. Adjust the pH of the batching tank to 10-10.5, and the temperature will rise by 5-8°C (if there is a lot of foam, add a small amount of defoamer if necessary).

[0065] (2) Heat exchange. After the batching is completed, the materials are pumped into the plate heat exchanger to exchange heat with the high-temperature materials that have been reacted once to heat up the materials.

[0066] (3) Once sprayed, the material after heat exchange is instantly mixed with steam through the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com