Assembling type frame structure joint

A frame structure and prefabricated technology, applied in the direction of building structure, construction, etc., can solve the problems of lack of advantages, labor and time, and the failure of the compound steel pipe concrete structure to be widely used, so as to promote the application and promotion, enhance the bearing capacity, Construct simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

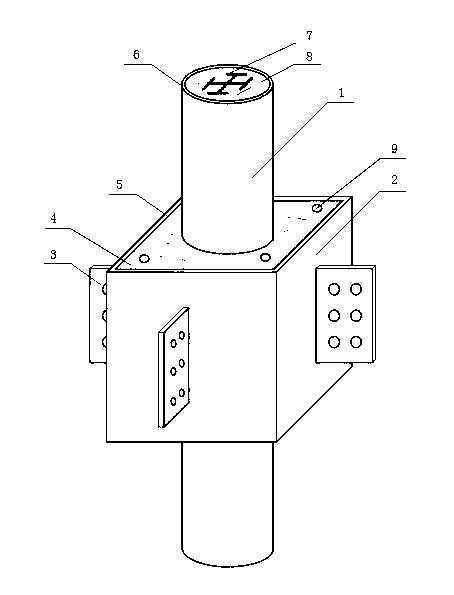

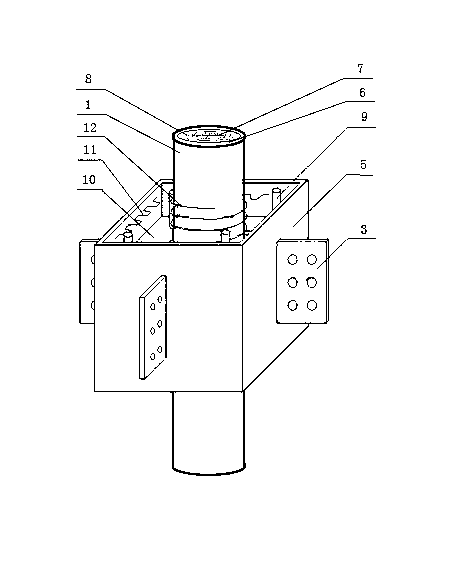

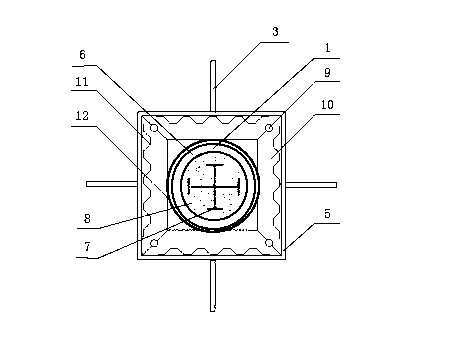

[0022] Such as figure 1 , 2 , 3, 4 shows an assembled frame structure node of the present invention, including: tenon column 1, pier column 2, splicing plate 3, concrete 4, pier column steel pipe 5, tenon column steel pipe 6, steel frame 7, concrete 8 , Screw perforation 9, stiffener 10, pin wire 11, spiral stirrup 12. Add concrete 4 to pier column steel pipe 5 to form pier column 2; add concrete 8 or steel bone 7 and concrete 8 to tenon column steel pipe 6 to form tenon column 1; the tenon column 1 is sleeved and connected to the hollow pier column steel pipe with the same axis 5, and both ends of the mortise column 1 protrude from the pier column steel pipe 5, and the fitting positions around the inner wall of the above pier column steel pipe 5 are provided with several pin wires 11; There are several stiffening ribs 10 ; spiral stirrups 12 are installed between the tenon column 1 and the pier column steel pipe 5 , and the spiral stirrups 12 are arranged around the tenon c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com