Method and device for measuring size of automobile aluminum hub finished product on line

A technology for aluminum alloy wheels and measurement methods, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of cumbersome process, inapplicability to shallow hole measurement, and inability to measure hole depth at the same time, so as to ensure product quality and measurement process Simple and fast, the effect of reducing the measurement process and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

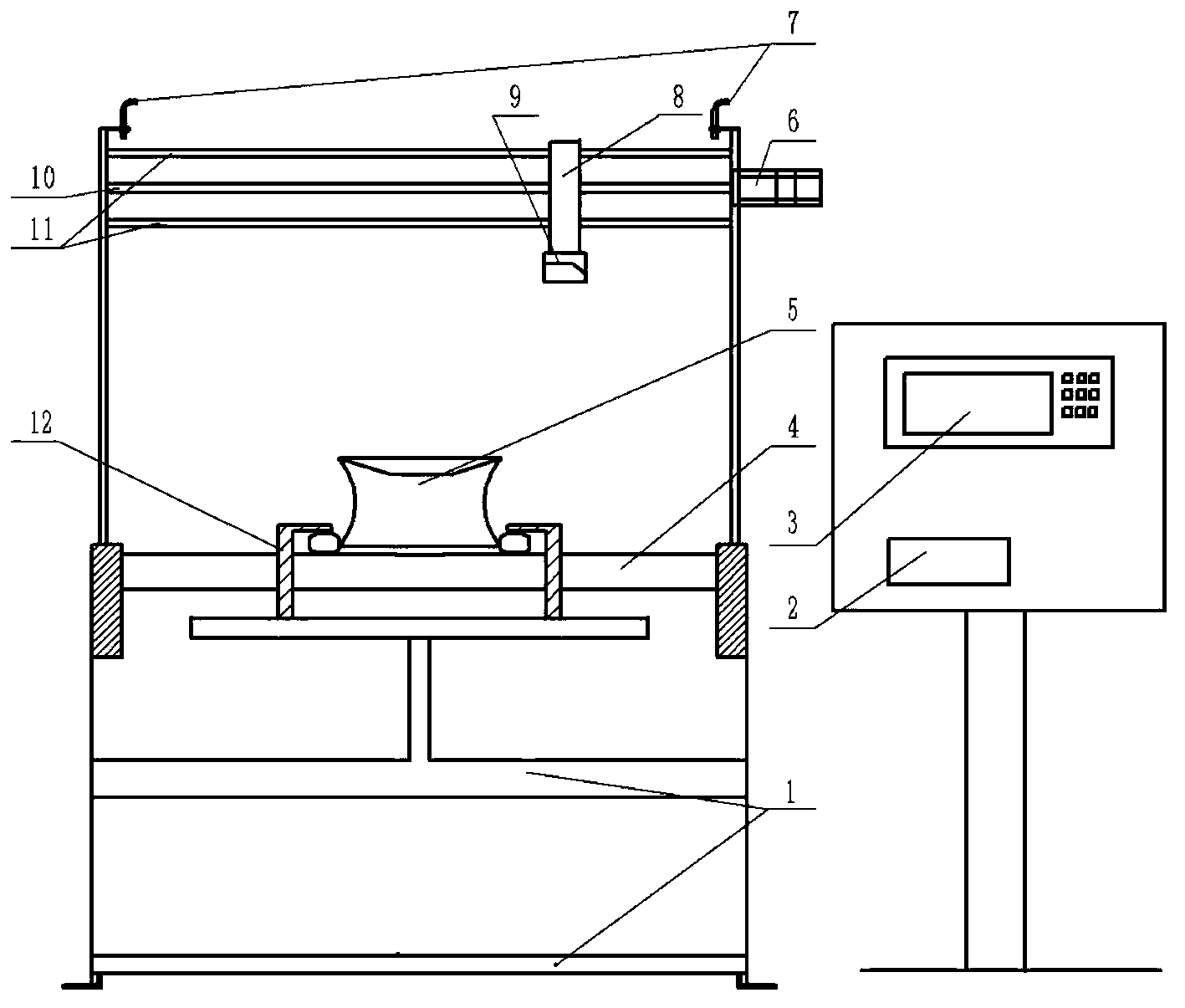

[0023] In order to further understand the content, features and functions of the present invention, an embodiment of the present invention is introduced below, and detailed description is as follows in conjunction with the accompanying drawings.

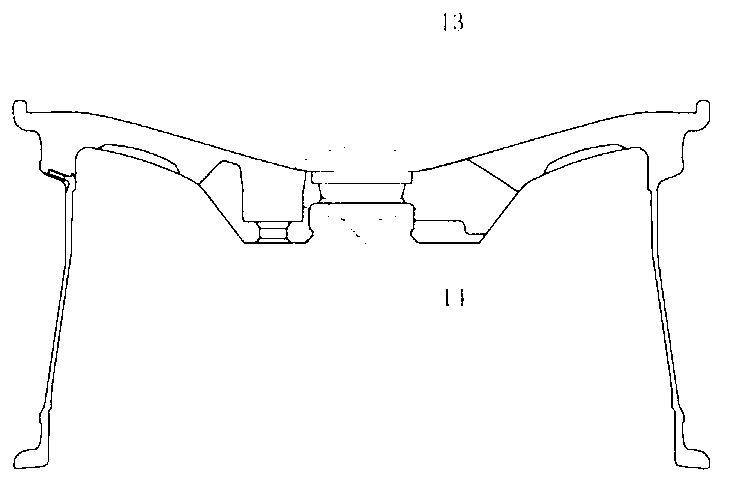

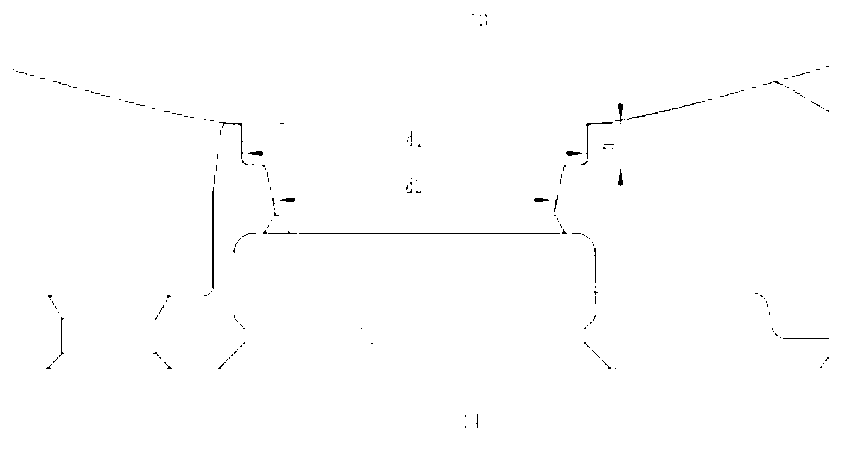

[0024] Please refer to Fig. 1-6, the present invention is based on the laser triangulation method and the measurement device and method for measuring the dimensions of the finished aluminum alloy wheel hub cap groove and cap opening on the line. The measurement device realizes the measurement through the following steps:

[0025] (1) Use measuring tools to adjust the installation position of the laser sensor 9 on the laser fixing mechanism 8 in advance to ensure that the connection direction of the light spots of the two laser sensors is perpendicular to the movement direction of the laser sensor 9 along the ball screw 10, adjust and measure the two laser sensors 9 The distance between the light spots, ensure that the distance is less...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com