High-precision display method of pressure-sensitive coating measuring result

A technology of measurement results and display methods, which is applied in the direction of measuring the change of optical properties of materials when they are stressed, and can solve problems such as the inability to directly provide pressure information, so as to improve display accuracy, improve conversion accuracy, and high space. The effect of resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Describe the present invention below in conjunction with specific embodiment:

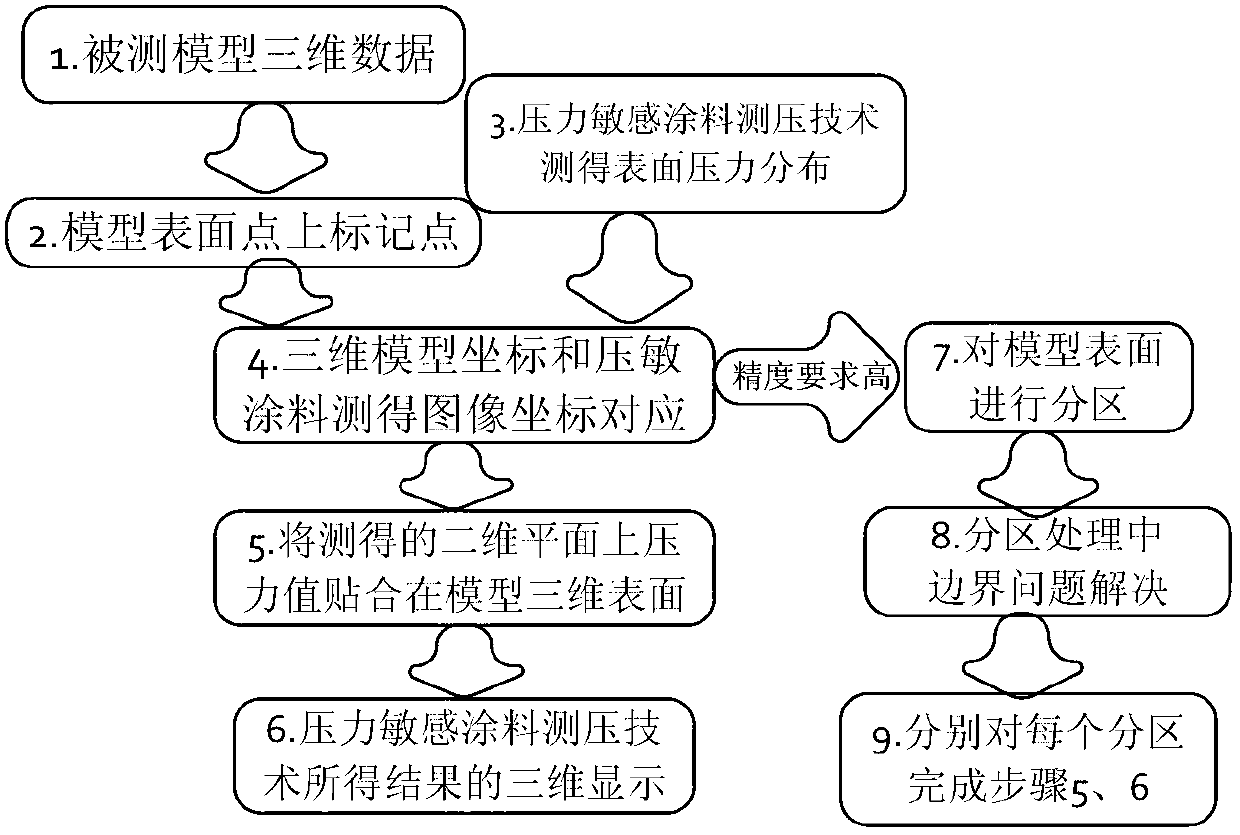

[0041] In this embodiment, the pressure-sensitive paint measurement technology is used to measure the surface pressure of the cascade, and the measurement results are displayed with high precision. Take the following steps:

[0042] Step 1: Obtain the 3D data of the model: In the general pressure-sensitive coating pressure test, the 3D data of the tested model is known. For the situation where the 3D data of the tested model is unknown, 3D scanning or other existing technologies can be used to analyze the 3D data of the tested model. Carry out three-dimensional scanning to obtain the three-dimensional coordinate data of the measured model, and construct the three-dimensional shape of the measured model.

[0043] Step 2: Divide the surface of the model under test into at least 5 large areas; in order to improve the display accuracy of pressure-sensitive paint pressure measurement results, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com