Determination method of cement concrete mixture water-cement ratio

A technology of cement concrete and measurement method, applied in the direction of material inspection products, etc., can solve the problems of high price of testing equipment, unfavorable promotion and use, etc., and achieve the effects of shortening drying time, increasing contact area, and reducing measurement error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

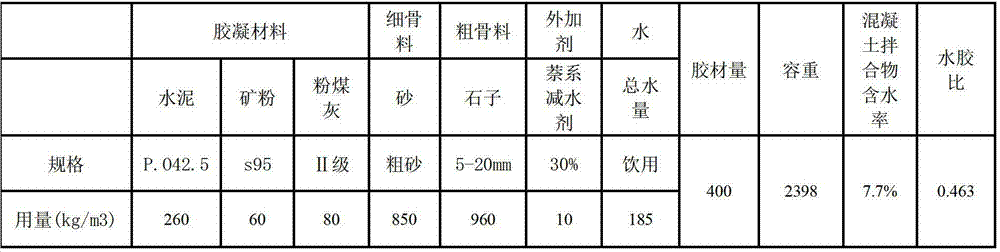

[0039] The concrete mix ratio is shown in Table 1.

[0040] Table 1 Concrete mix ratio

[0041]

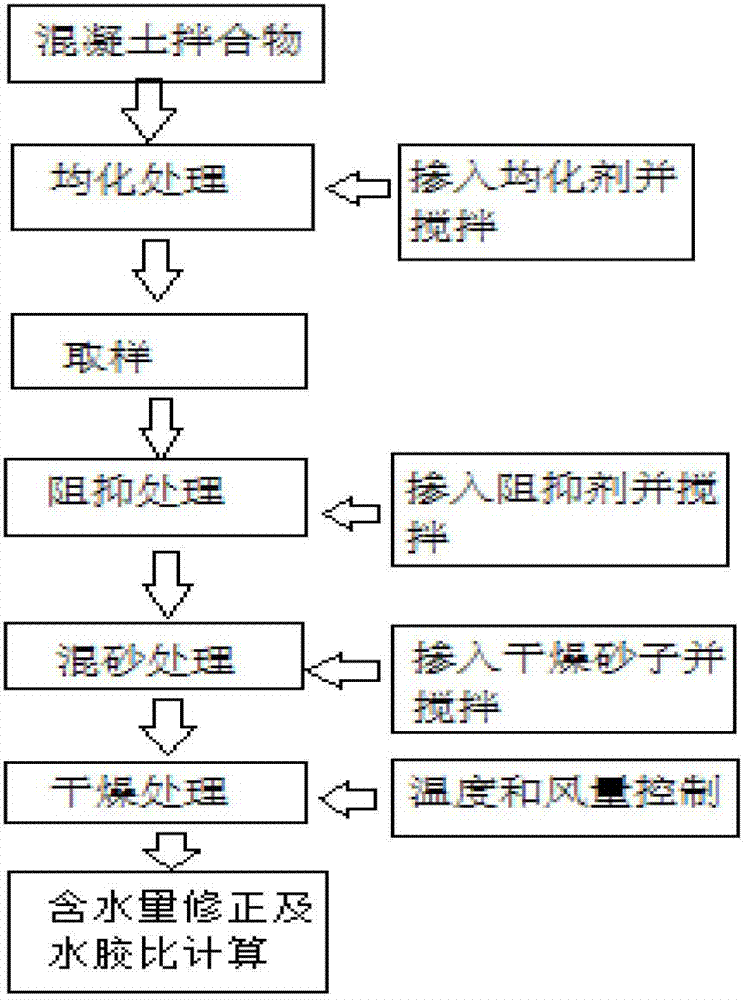

[0042] A kind of assay method of water-binder ratio of cement concrete mixture, concrete steps are as follows:

[0043] 1) Sampling the concrete mixture within the detection time limit, the specific steps are as follows: within the detection time limit, shovel two concrete mixture samples of the same quality from different diagonal directions of the concrete mixture, and the concrete mixing The mass of the material sample m 0 It is 400~500g, and the water-binder ratio is determined by taking the average value of the test results of two samples as the measured value. When the difference between the test results of the two samples is greater than 0.015, the sample should be re-sampled for testing.

[0044] The detection time limit refers to the period from the initial stage of cement hydration reaction to the rest period of hydration, which is within 1 hour after adding water t...

Embodiment 2

[0073] The test procedure is the same as in Example 1.

[0074] 1. Concrete mix ratio, see Table 5.

[0075] Table 5 Concrete mix ratio

[0076]

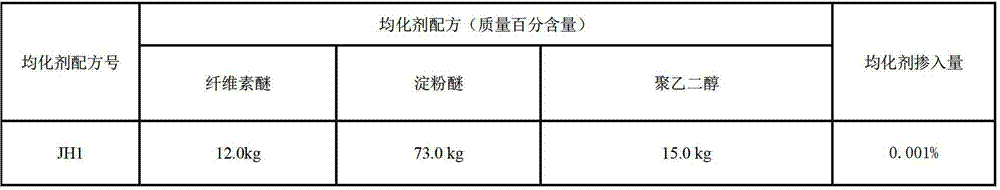

[0077] 2. See Table 6 for the formulation and dosage of leveling agent.

[0078] Table 6 Formula and dosage of leveling agent

[0079]

[0080]

[0081] 3. See Table 7 for the inhibitor formula and dosage.

[0082] Table 7 Repressor formula and dosage

[0083]

[0084] 4. The test results are as follows, see Table 8.

[0085] Table 8 Test results of water-binder ratio

[0086]

[0087] 5. Detection error value=0.370-0.372=-0.002<±0.015.

Embodiment 3

[0089] The test procedure is the same as in Example 1.

[0090] 1. Concrete mix ratio, see Table 9.

[0091] Table 9 Concrete mix ratio

[0092]

[0093] 2. See Table 10 for the formulation and dosage of leveling agent.

[0094] Table 10 Formula and dosage of leveling agent

[0095]

[0096] 3. See Table 11 for the inhibitor formula and dosage.

[0097] Table 11 Repressor formula and dosage

[0098]

[0099] 4. The test results are as follows, see Table 12.

[0100] Table 12 Test results of water-binder ratio

[0101]

[0102] 5. Detection error value=0.344-0.337=0.007<±0.015.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com