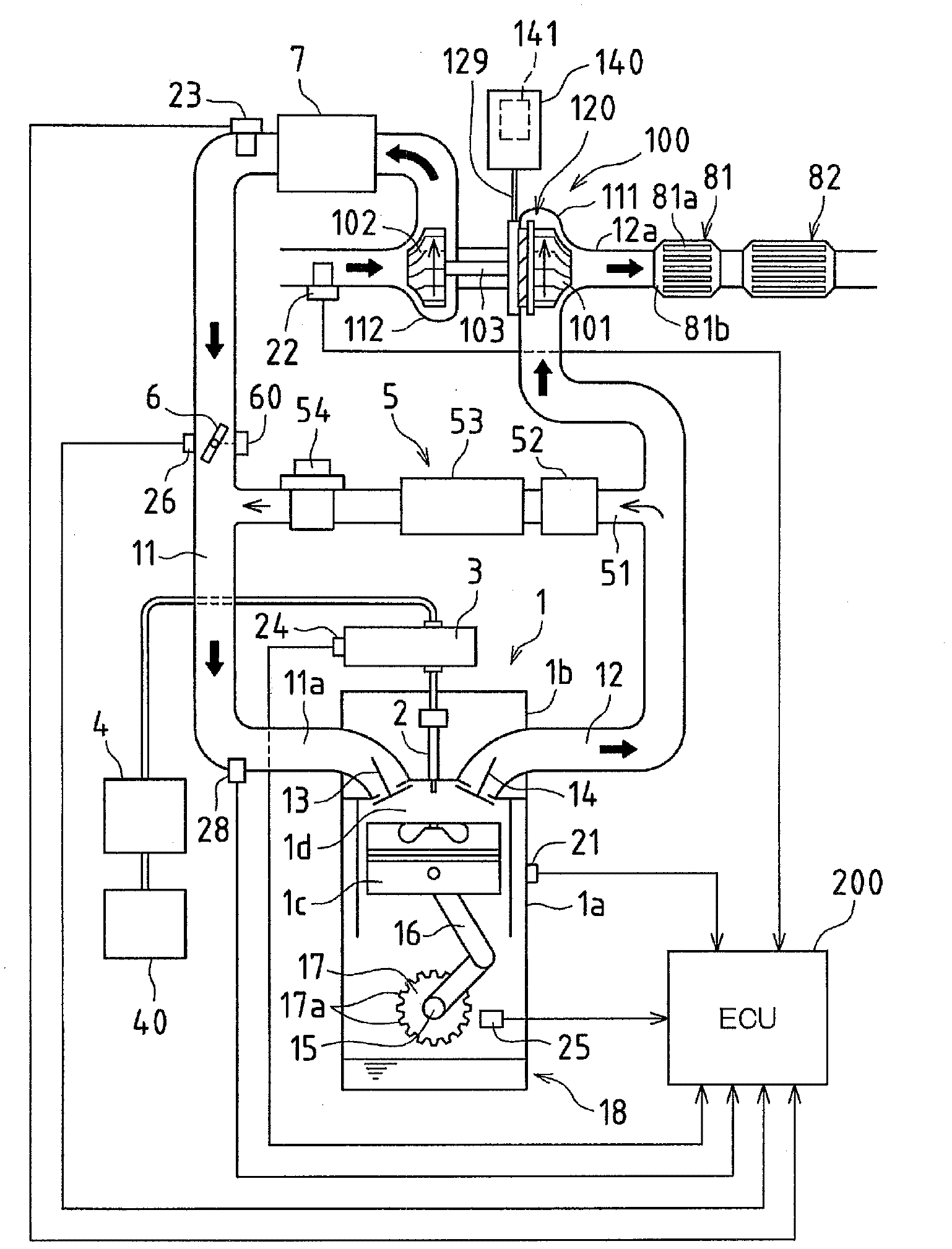

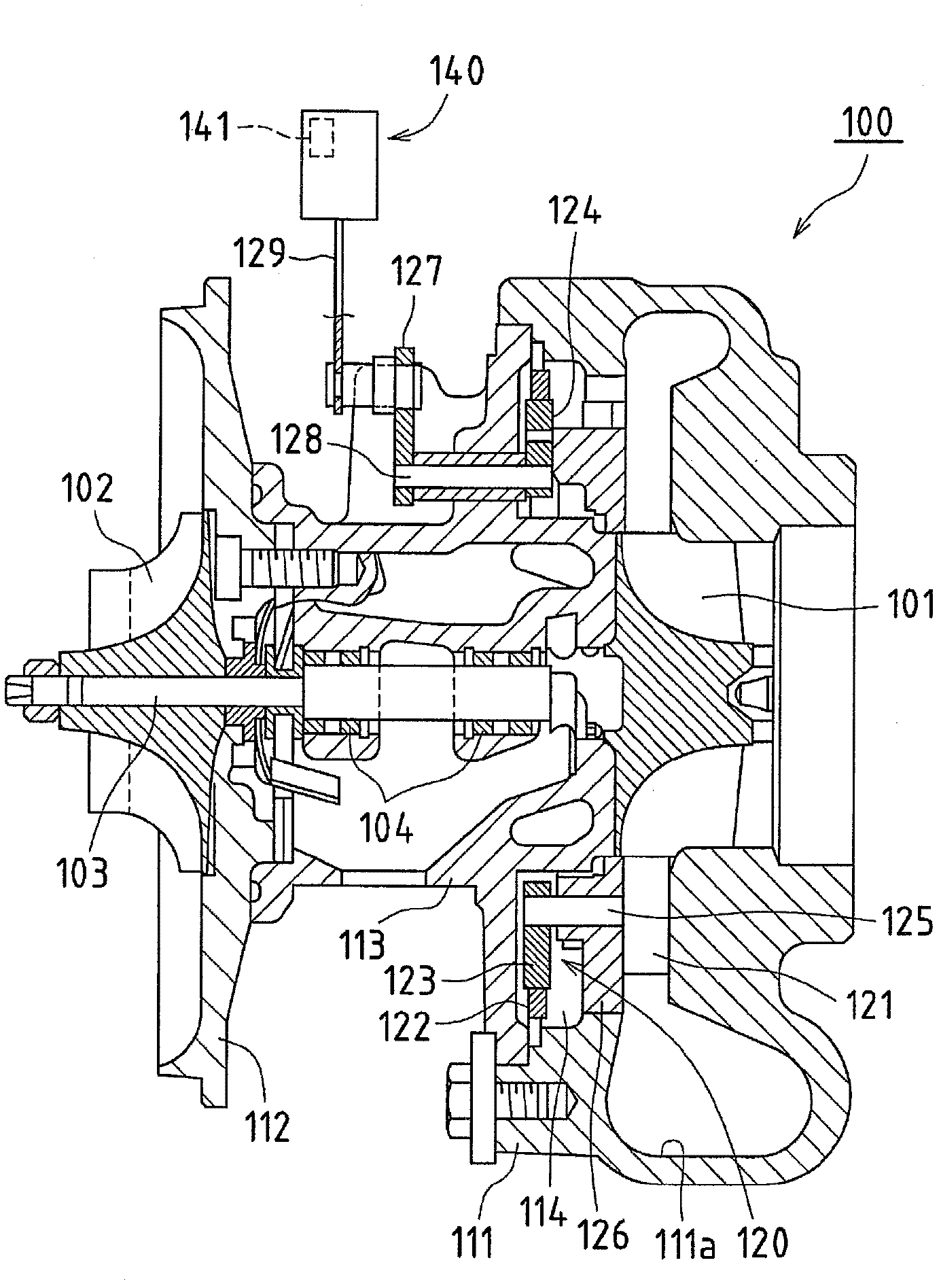

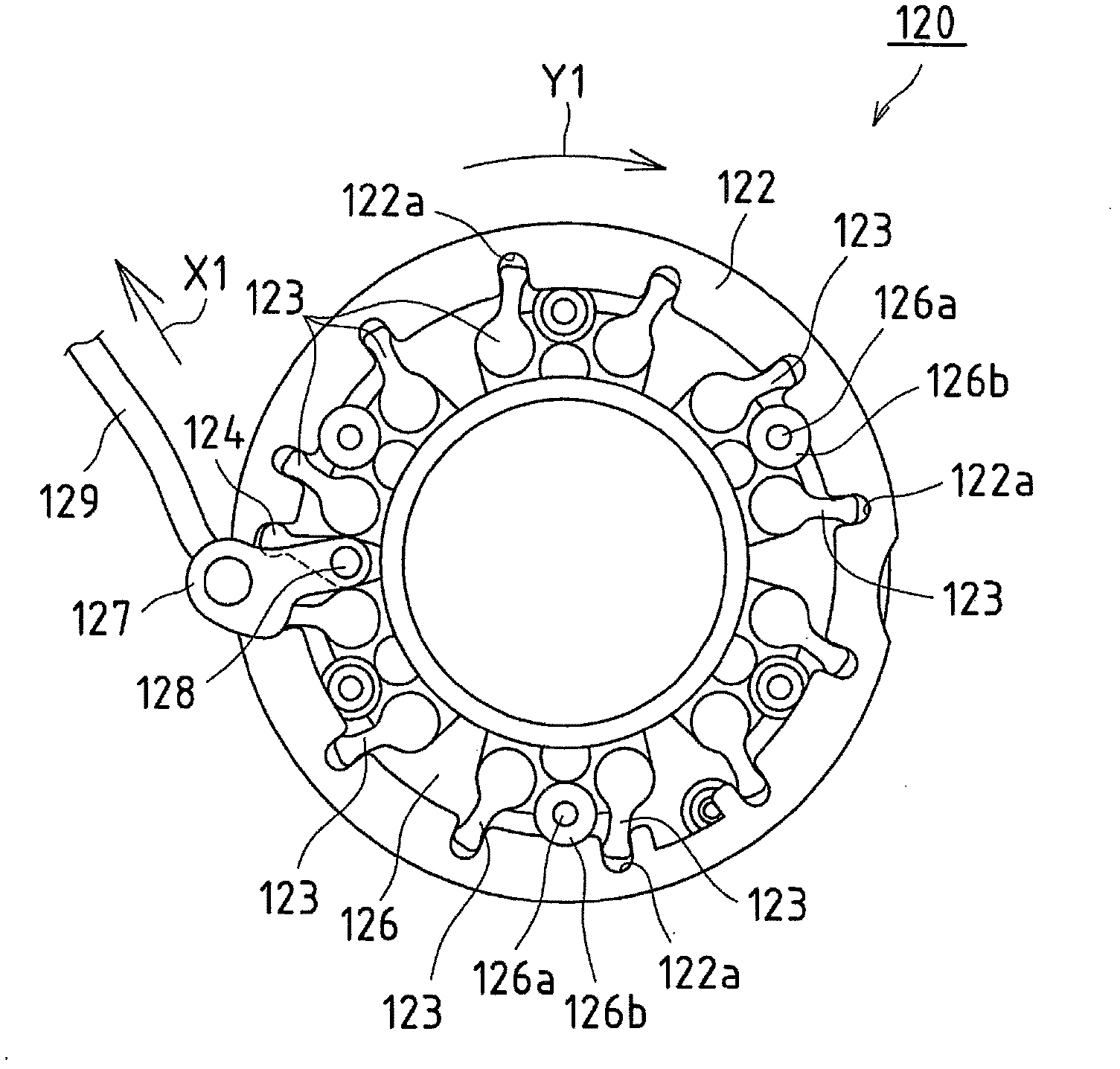

Apparatus for controlling internal combustion engine provided with turbocharger

A technology of control device and supercharger, applied in engine control, internal combustion piston engine, electrical control, etc., can solve the problems of difficulty in suppressing abnormal noise, low degree of freedom in hardware design, low degree of freedom, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0165] In the above examples, the case where the present invention is applied to a common rail direct injection multi-cylinder (four-cylinder) diesel engine has been described. However, the present invention is not limited thereto, and can be applied to other diesel engines having any number of cylinders, such as six-cylinder diesel engines, for example.

[0166] In addition, in the above examples, an example of control of a diesel engine was described, but the present invention is not limited thereto, and the present invention can also be applied to the control of a gasoline engine equipped with a variable nozzle vane turbocharger. .

[0167] In the above examples, the case where the present invention is applied to an internal combustion engine (diesel engine, gasoline engine, etc.) equipped with an EGR device (exhaust gas recirculation device) has been described, but the present invention is not limited thereto. The present invention can also be applied to the control of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com