Preparation method of self-assembly covalent cross-linked sodium filter membrane

A covalent cross-linking, nanofiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the increase in the use cost and operating cost of membrane modules, reduce filtration efficiency and membrane water production, increase The number of membrane replacements and other issues can enhance the anti-biological fouling ability, good effect, high solvent resistance and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

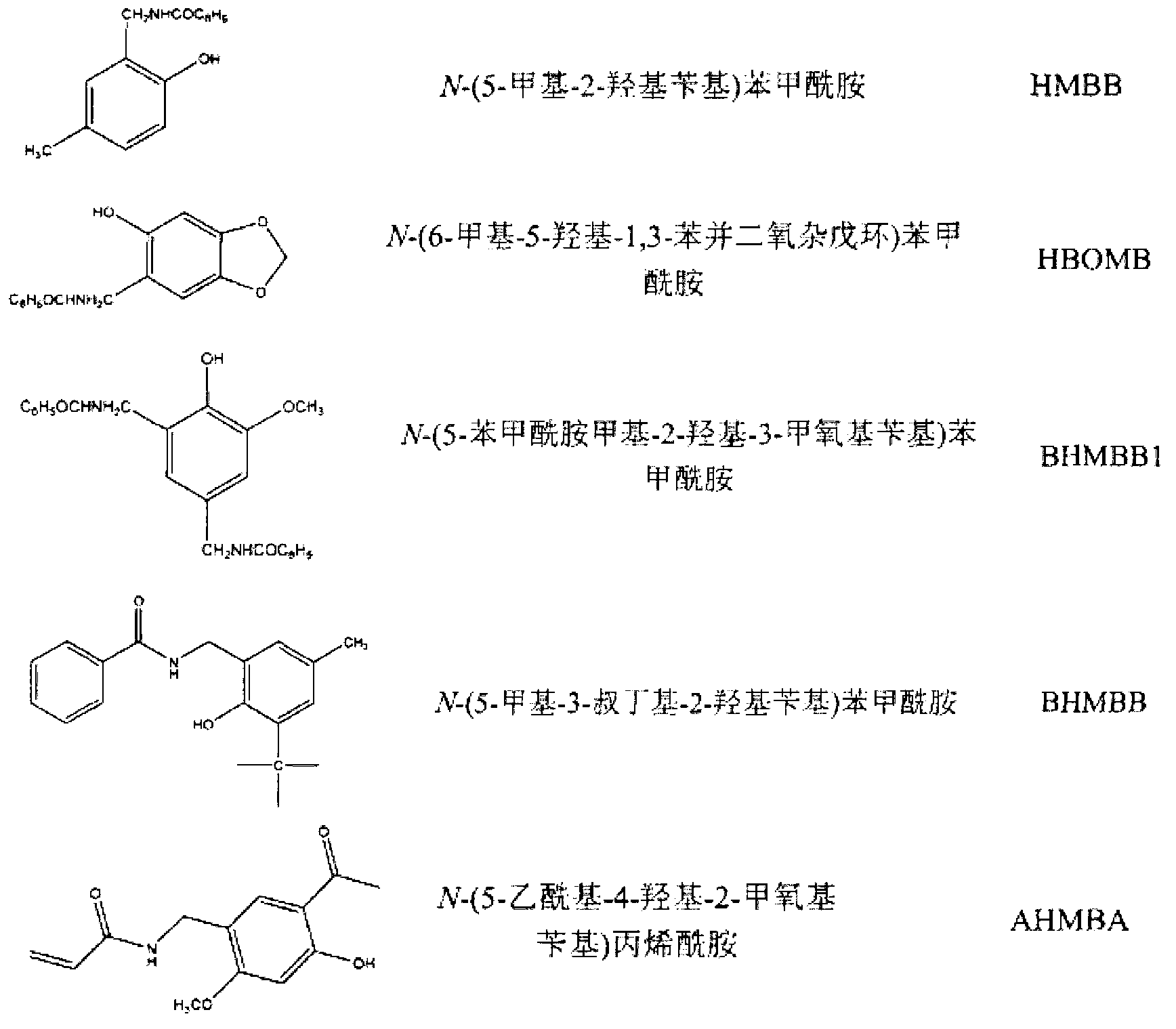

[0030] The base membrane used in the present invention is a polyacrylonitrile (PAN) membrane with a molecular weight cut-off of 50,000 Da (Dalton), a flat ultrafiltration membrane, and a membrane area of 28.26cm 2 ; The polyanionic electrolyte used is sodium polyacrylate (PAA, with a molecular weight of 100,000); the polycationic electrolyte used is polyethyleneimine (PEI, with a molecular weight of 60,000), and the molecular weight of glutaraldehyde (GA) is 100; The functional monomer N-(5-methyl-2 hydroxybenzyl)benzamide (HMBB) of the prime is made by the laboratory, and its preparation steps are as follows:

[0031] (1) Prepare a polycation electrolyte solution with absolute ethanol, wherein the mass percentage concentration of PEI is 0.4%, and the mass percentage concentration of HMBB is 0.25%;

[0032] (2) Prepare a PAA solution with a mass percent concentration of 0.25% with deionized water;

[0033] (3) Prepare a GA solution with a mass percent concentration of 0.5% ...

Embodiment 2

[0042] The base membrane, polycation electrolyte, and polyanion electrolyte used in this embodiment are the same as in Example 1, and the preparation steps are as follows:

[0043] (1) Prepare a polycation membrane-making solution with absolute ethanol, wherein the mass percentage concentration of PEI is 0.4%, and the mass percentage concentration of HMBB is 0.25%;

[0044] (2) Prepare a PAA solution with a mass percent concentration of 0.25% with deionized water;

[0045] (3) Prepare a GA solution with a mass percent concentration of 0.5% with deionized water;

[0046] (4) In order to charge the surface of the polyacrylonitrile-based membrane, the hydrolytic modification technology was used to immerse the polyacrylonitrile ultrafiltration membrane in 2N NaOH solution for 1 hour at a constant temperature of 65°C to modify it into a polyanion-based membrane. membrane;

[0047] (5) Rinse off the NaOH solution on the surface of the membrane with deionized water until the pH val...

Embodiment 3

[0054] The base membrane, polycation electrolyte, and polyanion electrolyte used in this embodiment are the same as in Example 1, and the preparation steps are as follows:

[0055] (1) Prepare a polycation membrane-making solution with absolute ethanol, wherein the mass percentage concentration of PEI is 0.4%, and the mass percentage concentration of HMBB is 0.25%;

[0056] (2) Prepare a PAA solution with a mass percent concentration of 0.25% with absolute ethanol;

[0057] (3) Prepare a GA solution with a mass percent concentration of 1% with deionized water;

[0058] (4) In order to charge the surface of the polyacrylonitrile-based membrane, the hydrolytic modification technology was used to immerse the polyacrylonitrile ultrafiltration membrane in 2N NaOH solution for 1 hour at a constant temperature of 65°C to modify it into a polyanion-based membrane. membrane;

[0059] (5) Rinse off the NaOH solution on the surface of the membrane with deionized water until the pH valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com