White glaze printing ink for ceramic ink-jet printing and preparation method thereof

A ceramic inkjet and glaze technology, which is applied in the fields of inks, applications, household appliances, etc., can solve the problems of less research and reports on ceramic white inks, insufficient whiteness, etc., and achieve good quality stability, low viscosity, and particle size distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

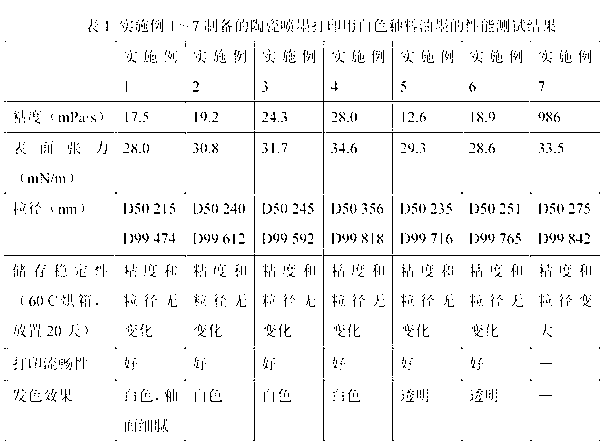

Examples

preparation example Construction

[0037] The preparation method of above-mentioned ceramic ink-jet printing white glaze ink, comprises the following steps:

[0038] 1) Mix part of the solvent, resin, dispersant and ceramic glaze, disperse evenly, and make the glaze fully wet;

[0039] 2) Grinding the dispersed glaze, controlling the average particle size of the glaze to be 200-400 nm, and the maximum particle size is less than 900 nm, to obtain glaze slurry;

[0040] 3) Add leveling agent, defoamer, anti-sedimentation agent and remaining solvent to the glaze slurry, and filter to obtain white glaze ink for ceramic inkjet printing.

Embodiment 1

[0044]A white glaze ink for ceramic inkjet printing, which consists of the following components by mass percentage: 30% white ceramic glaze, 2% acrylic resin (NeoCryl B-725), polyacrylate dispersant (EFKA4400) 3%, leveling agent (BYK333) 0.2%, defoamer (BYK052) 0.7%, anti-settling agent (Disparlon NS-5501) 0.1%, dipropylene glycol butyl ether 18.5%, propylene glycol butyl ether 45.5%.

[0045] The composition of white glaze material used in this embodiment is: SiO 2 40 parts, Al 2 o 3 15 copies, K 2 O 4 parts, Na 2 O 4 parts, CaO 4 parts, MgO 4 parts, ZrSiO 4 8 copies, B 2 o 3 6 parts, ZnO 6 parts, CeO 2 9 parts, by mass.

Embodiment 2

[0047] A white glaze ink for ceramic inkjet printing, which consists of the following components by mass percentage: white ceramic glaze 50%, vinyl acetate resin (Wacker H14 / 36) 6%, polyurethane dispersant (Nuosperse FX9086) 6%, leveling agent (Levaslip 8629) 0.2%, defoamer (BYK051) 0.6%, anti-settling agent (Disparlon 6650) 0.1%, diethylene glycol butyl ether acetate 20%, propylene glycol methyl ether acetate 17.1% .

[0048] The composition of white glaze material used in this embodiment is: SiO 2 50 parts, Al 2 o 3 14 copies, K 2 2 parts of O, Na 2 2 parts of O, 4 parts of CaO, 2 parts of MgO, ZrSiO 4 5 copies, B 2 o 3 6 parts, ZnO 6 parts, CeO 2 9 parts, by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com