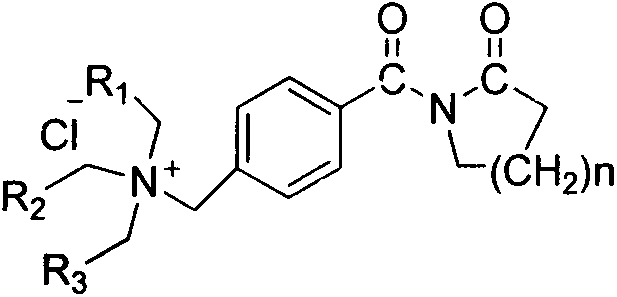

Preparation and application method of fabric normal-temperature rinsing system

An application method and fabric technology, applied in the direction of bleaching products, textiles, and papermaking, can solve the problems of low hydrogen peroxide activation efficiency, reduced bleaching efficiency, and low water solubility, and achieve small fabric damage, high rinsing efficiency, and high temperature less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

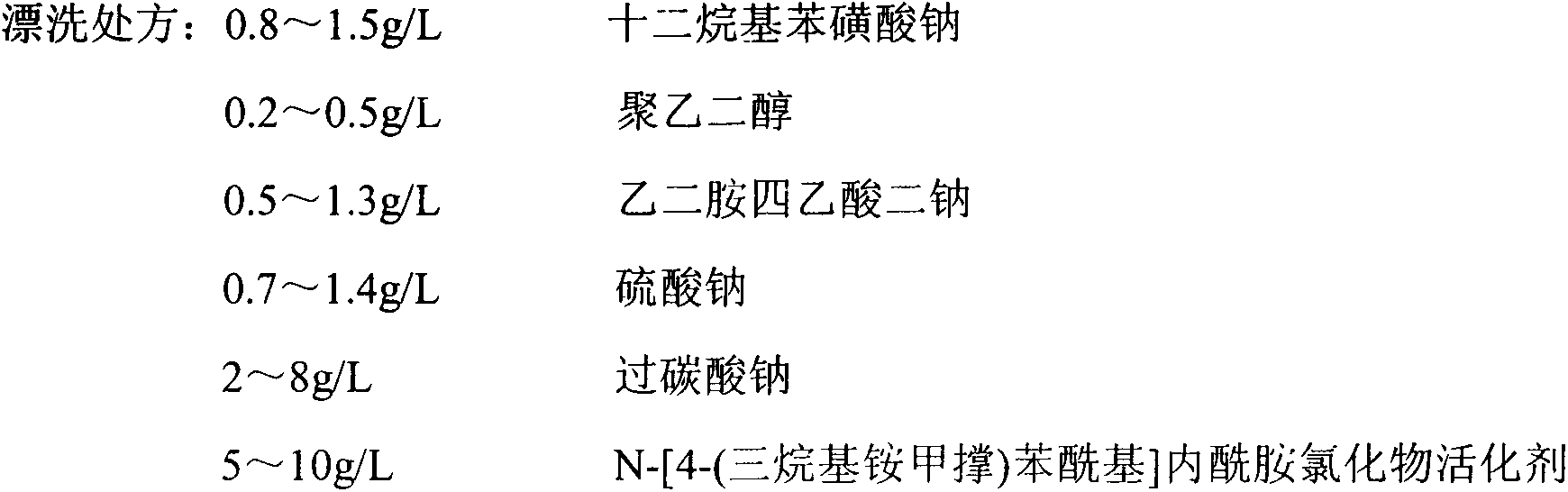

example 1

[0019] Fabric: Refined Cotton Knit

[0020]

[0021] Bath ratio: 50:1

[0022] Temperature: 25°C

[0023] Time: 30 minutes

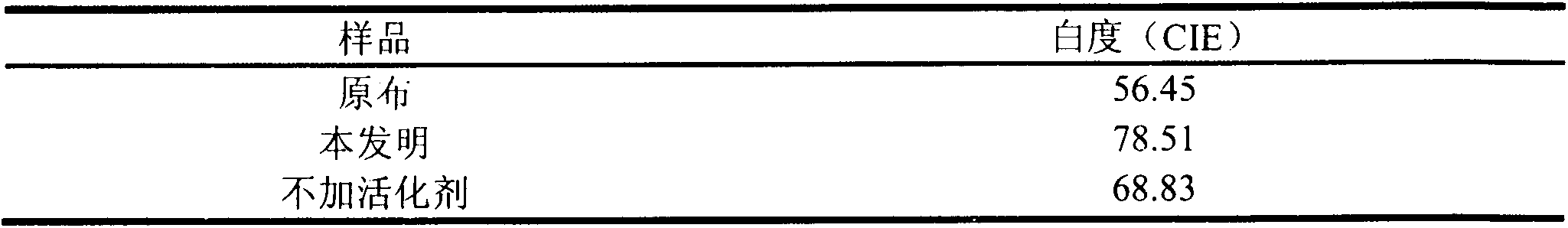

[0024] The present invention contrasts with the bleaching result when not adding activator:

[0025]

example 2

[0027] Fabric: Woven bleached chintz, soaked in strong tea water for 5 minutes and dried directly

[0028]

[0029] Temperature: 30°C

[0030] Time: 40 minutes

[0031] The present invention contrasts with the bleaching result when not adding activator:

[0032]

example 3

[0034] Fabric: Woven bleached chintz, soaked in espresso for 5 minutes and dried directly

[0035]

[0036] Temperature: 25°C

[0037] Time: 30 minutes

[0038] The present invention contrasts with the bleaching result when not adding activator:

[0039]

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com