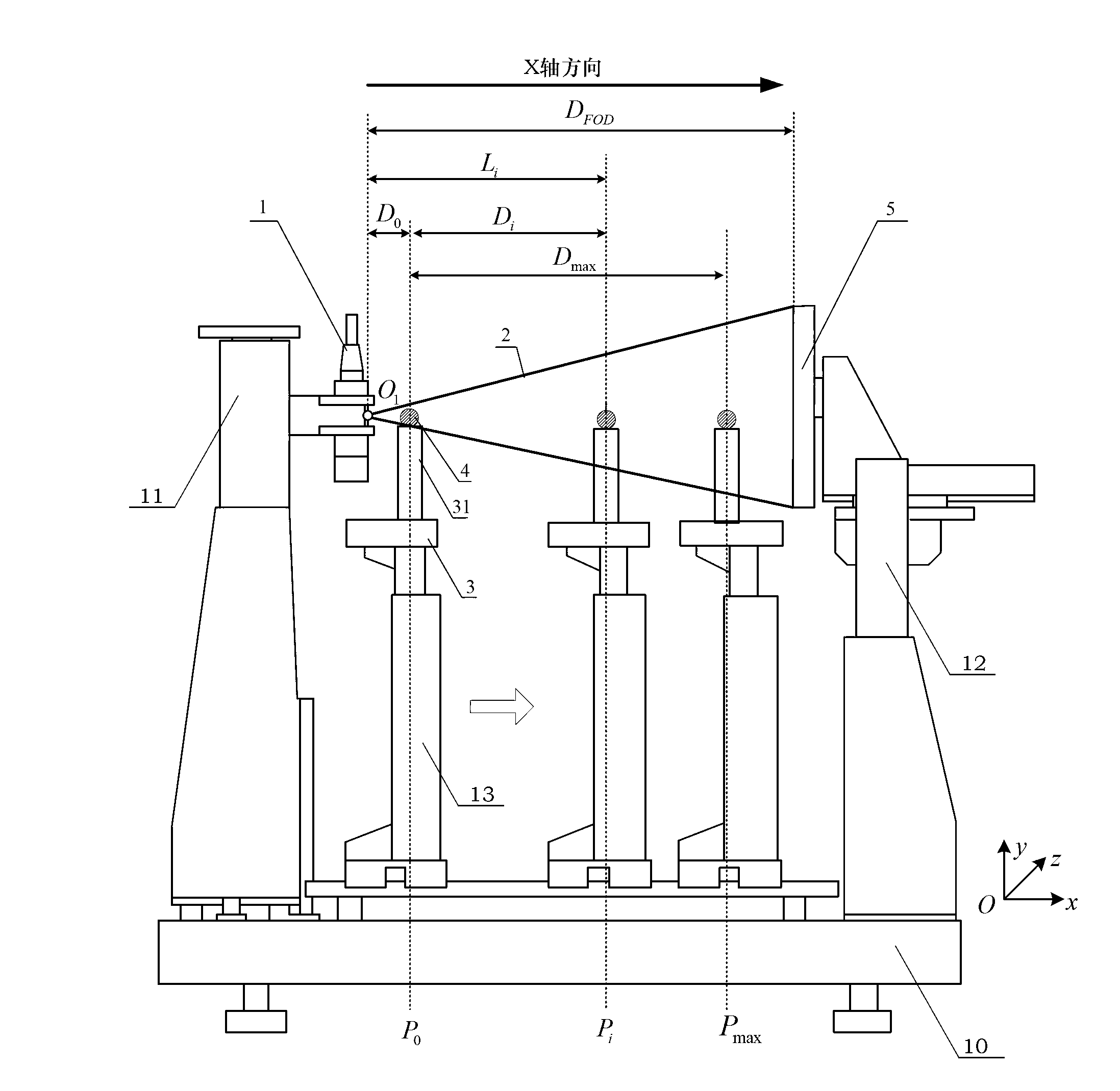

Automatic calibration method for reconstructing voxel sizes of cone beam 3D-CT scanning system

A 3D-CT, voxel size technology, which is applied in the direction of material analysis using radiation, can solve the problems of low precision and difficult projection geometric magnification ratio, and achieve the effect of high precision, simple implementation and reduced improvement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

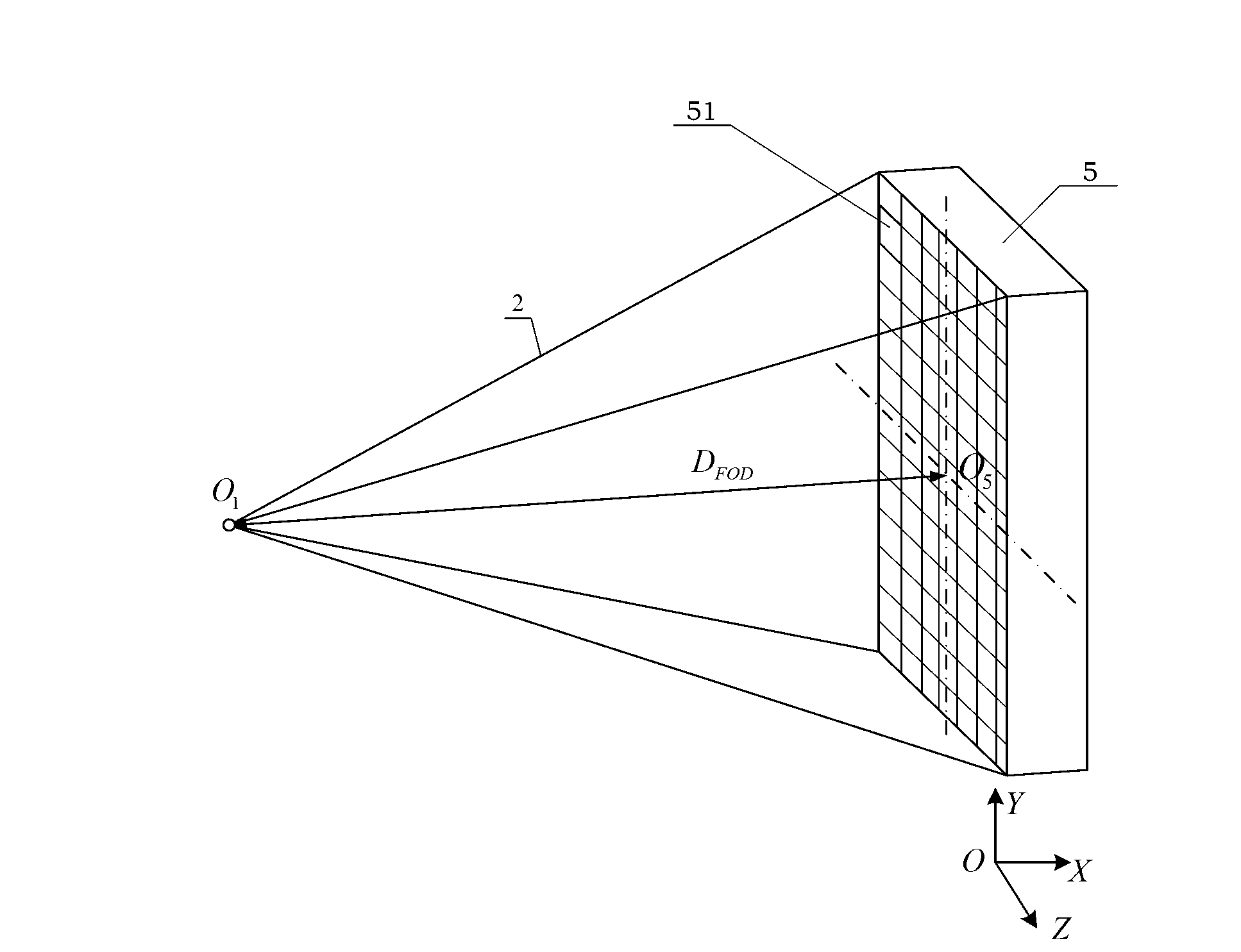

Method used

Image

Examples

Embodiment

[0114] The voxel size of a certain cone beam 3D-CT scanning system is automatically calibrated by using the calibration method of the present invention. The spherical target used in the verification is a steel ball with a diameter of 19mm. The physical size of the detection unit is 0.2mm. Figure 2A , Figure 2B , Figure 2C and Figure 2D is the DR image of the steel ball at a certain imaging position and the contour map extracted after image processing, which corresponds to D i = 330mm. Table 1 shows the measurement results of different travel distances of the verification turntable. Plot D of Table 1 i -V i relationship diagram, such as image 3 As shown, it can be seen that the relationship between the travel distance of the turntable and the voxel size is a linear linear function relationship, which proves the correctness of the above inference.

[0115] Input the linear equation fitted by the data in Table 1 into the automatic calibration module of the cone beam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com