Method for replacing insulator chains in 220 kV long-span high tower in live working

A technology for pendant insulators and live replacement, applied in overhead lines/cable equipment and other directions, can solve the problems of complex cross arm structure, low work efficiency, inability to find, etc., to achieve safety and controllability, strong teaching and simple operation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Best practice:

[0060] First, let’s introduce the various tools required:

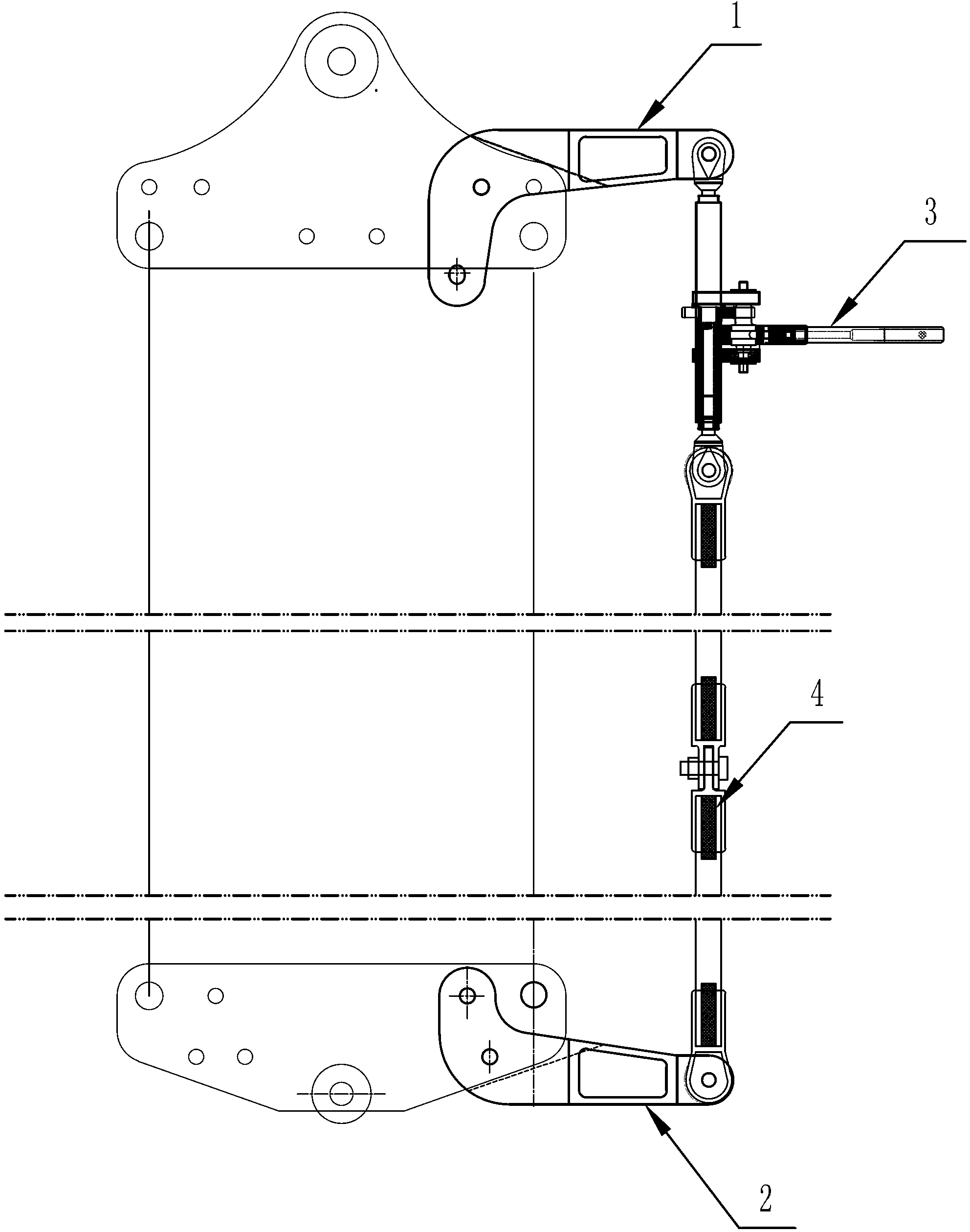

[0061] Working tools for live replacement of insulator strings: refer to the attached figure 1 , including an upper clamp 1, a lower clamp 2, a wire tightener 3 and an insulating pull rod 4, and the lower end of the wire tightener 3 is connected with the insulating pull rod 4.

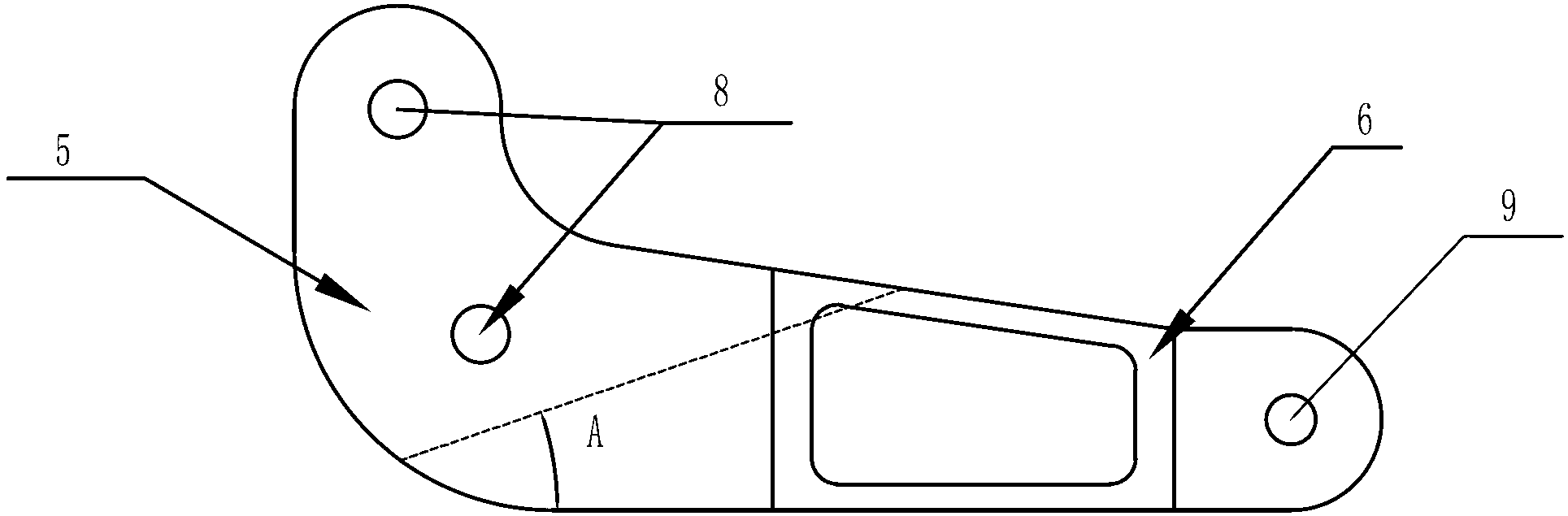

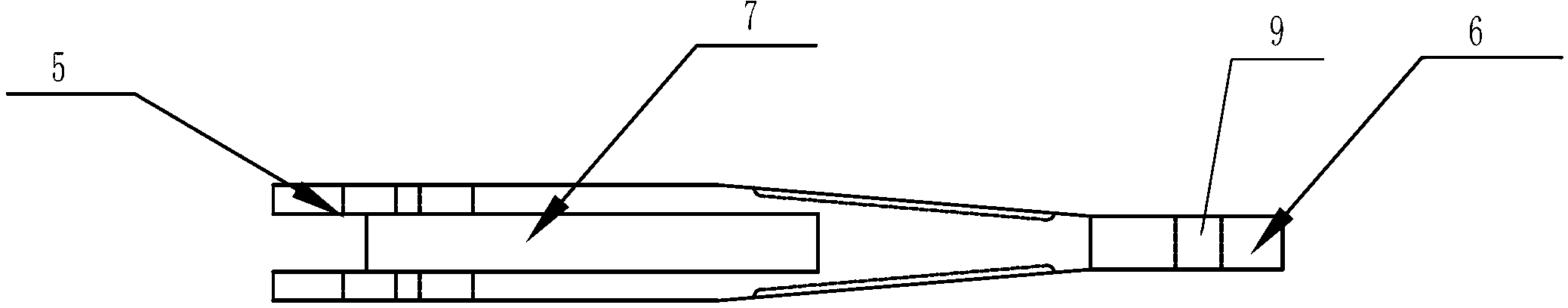

[0062] Refer to attached figure 2 And attached image 3 , combined with the attached figure 1 , the upper fixture 1 and the lower fixture 2 are both a bent plate fixture, including a left clamp 5 and a right clamp 6, the left clamp 5 is in the shape of an open fork, and the thickness of the fork groove 7 is greater than that of the insulator string to be replaced. The thickness of the connecting plate, the left card 5 is inclined relative to the right card 6, and the junction of the two is close to the root of the left card 5 fork groove 7, and the clamp is integrally in a bent shape. There are two screw holes 8 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com