Vacuum continuous casting device and method for alloy billets

A billet and alloy technology, which is applied in the field of vacuum continuous casting equipment for alloy billets, can solve the problems of large process material consumption, complicated processing procedures, and high production costs, and achieve the goals of reducing power consumption and heat energy loss, improving utilization efficiency, and solving waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

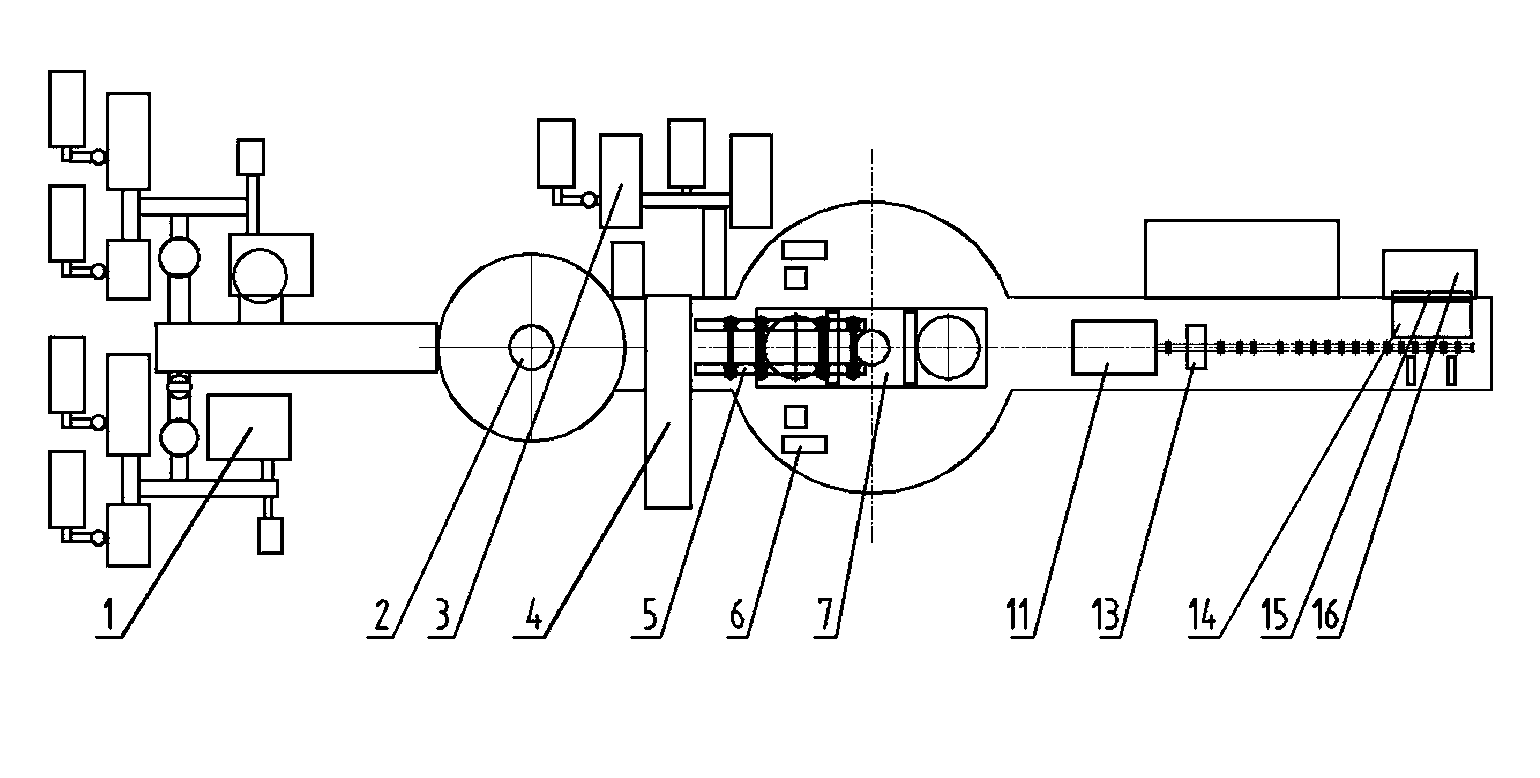

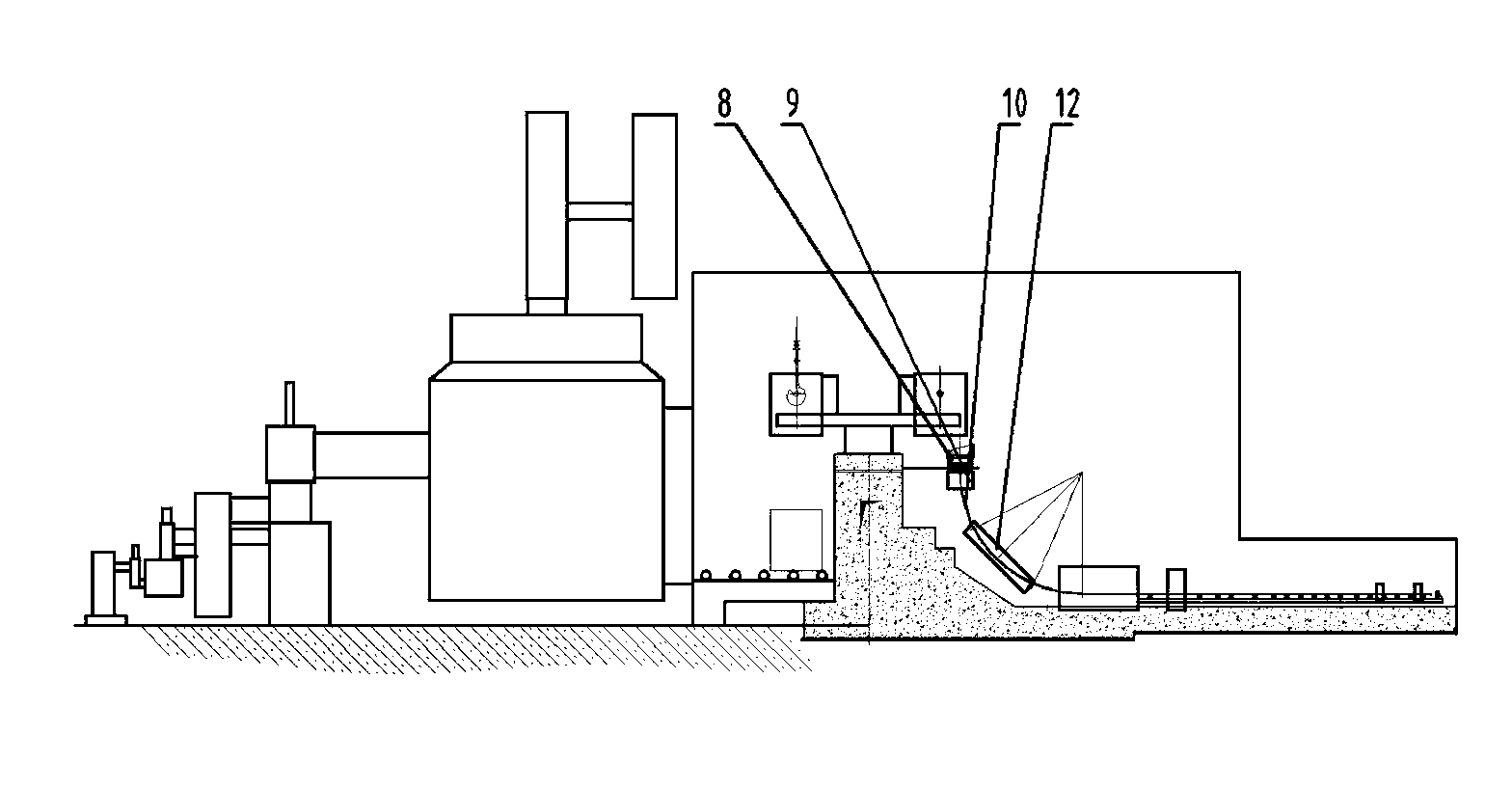

[0029] The detailed description and technical content of the present invention are described below in conjunction with the accompanying drawings. However, the accompanying drawings are only provided for reference and description, and are not used to limit the present invention.

[0030] according to Figure 1-2 As shown, the vacuum continuous casting device of alloy billet includes a melting chamber and a mold chamber. The melting chamber is provided with a melting system 2, and the mold chamber is sequentially provided with a molten steel pouring system 8 and a collection system; the melting chamber and the main vacuum system 1 pass through The pipeline is connected with a valve, and the mold chamber and the auxiliary vacuum system 3 are connected by pipelines and valves; the melting chamber and the mold chamber are separated by a main and auxiliary vacuum isolation valve 4. The main vacuum system and the auxiliary vacuum system are equipped with vacuum instruments and gas charg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com