Device for vacuum laser welding

A laser welding and vacuum technology, which is applied in the field of laser welding devices and welding and vacuum laser welding devices, can solve the problems of unreasonable design of clamping mechanism and linkage mechanism, complicated clamping of parts to be welded, and low welding production efficiency. Achieve the effects of improving vacuum laser welding productivity, convenient and quick assembly, and short vacuuming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

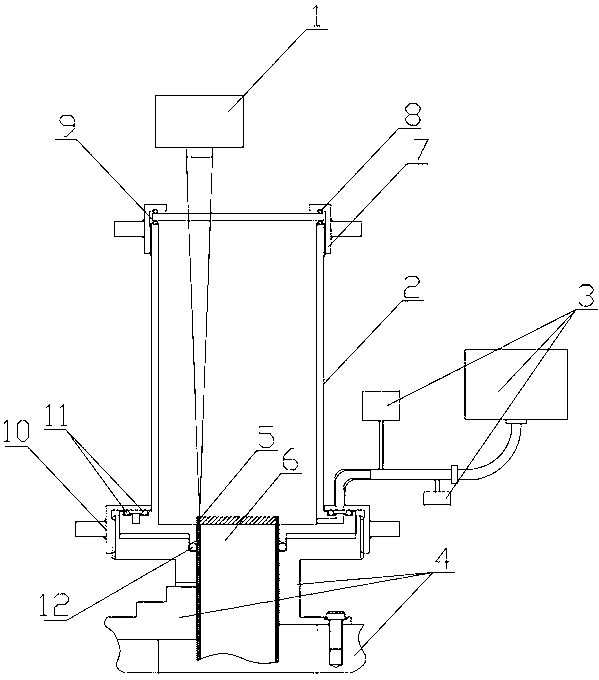

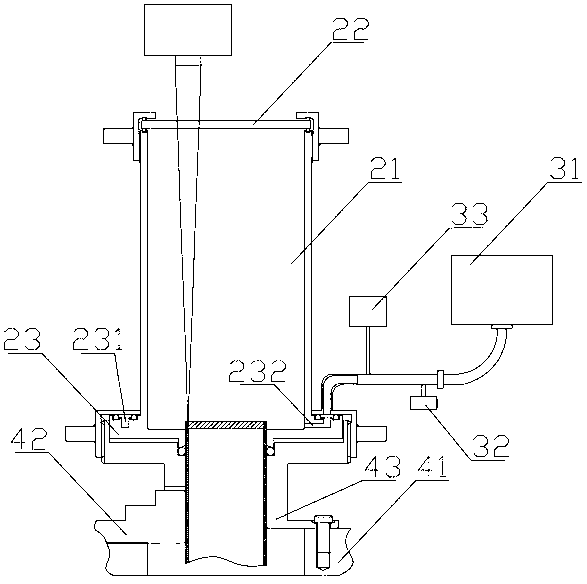

[0034] A device for vacuum laser welding, including laser welding equipment 1, vacuum chamber assembly 2, vacuum pumping assembly 3 and support clamping assembly 4, the vacuum chamber assembly 2 includes a vacuum chamber 21 and is arranged in the vacuum chamber The processing window 22 on the top of 21, the laser welding equipment 1 is located above the vacuum chamber assembly 2, the vacuum pumping assembly 3 is sealed and connected to the vacuum cavity 21 through a pipeline, and the support clamping assembly 4 includes The chuck disc body 41, the clamping jaws 42 and the fixing bracket 43, the top of the fixing bracket 43 is sealed and connected with the bottom of the vacuum cavity 21, and the bottom of the fixing bracket 43 is fixed on the chuck On the disc body 41, the chuck disc body 41 is provided with clamping jaws 42; the bottom of the vacuum cavity 21 is provided with a hole 6 for the workpiece to be welded, and the workpiece 5 to be welded is formed by the clamping jaw...

Embodiment 2

[0036]A device for vacuum laser welding, including laser welding equipment 1, vacuum chamber assembly 2, vacuum pumping assembly 3 and support clamping assembly 4, the vacuum chamber assembly 2 includes a vacuum chamber 21 and is arranged in the vacuum chamber The processing window 22 on the top of 21, the laser welding equipment 1 is located above the vacuum chamber assembly 2, the vacuum pumping assembly 3 is sealed and connected to the vacuum cavity 21 through a pipeline, and the support clamping assembly 4 includes The chuck disc body 41, the clamping jaws 42 and the fixing bracket 43, the top of the fixing bracket 43 is sealed and connected with the bottom of the vacuum cavity 21, and the bottom of the fixing bracket 43 is fixed on the chuck On the disc body 41, the chuck disc body 41 is provided with clamping jaws 42; the bottom of the vacuum cavity 21 is provided with a hole 6 for the workpiece to be welded, and the workpiece 5 to be welded is formed by the clamping jaws...

Embodiment 3

[0039] On the basis of embodiment 1:

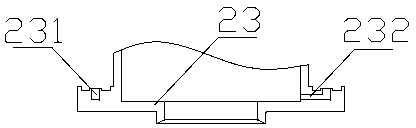

[0040] Preferably, the top of the vacuum chamber 21 is open, and the processing window 22 is sealed and connected to the opening at the top of the vacuum chamber 21 through the processing window sealing fastening ring 7 to cover the opening at the top of the vacuum chamber 21 .

[0041] Furthermore, the processing window sealing fastening ring 7 presses the processing window 22 on the edge of the top opening of the vacuum cavity 21, and a processing window 22 is arranged between the processing window sealing fastening ring 7. The sealing ring 8 on the window, the lower sealing ring 9 of the processing window is arranged between the processing window 22 and the edge of the top opening of the vacuum cavity 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com