Internal-external full-automatic polisher for treating inner ring and outer ring of passenger train bearing

A circular, fully automatic, inner and outer ring technology, used in grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems of low work efficiency, simple structure, large volume, etc., to improve efficiency and quality, and improve polishing accuracy. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

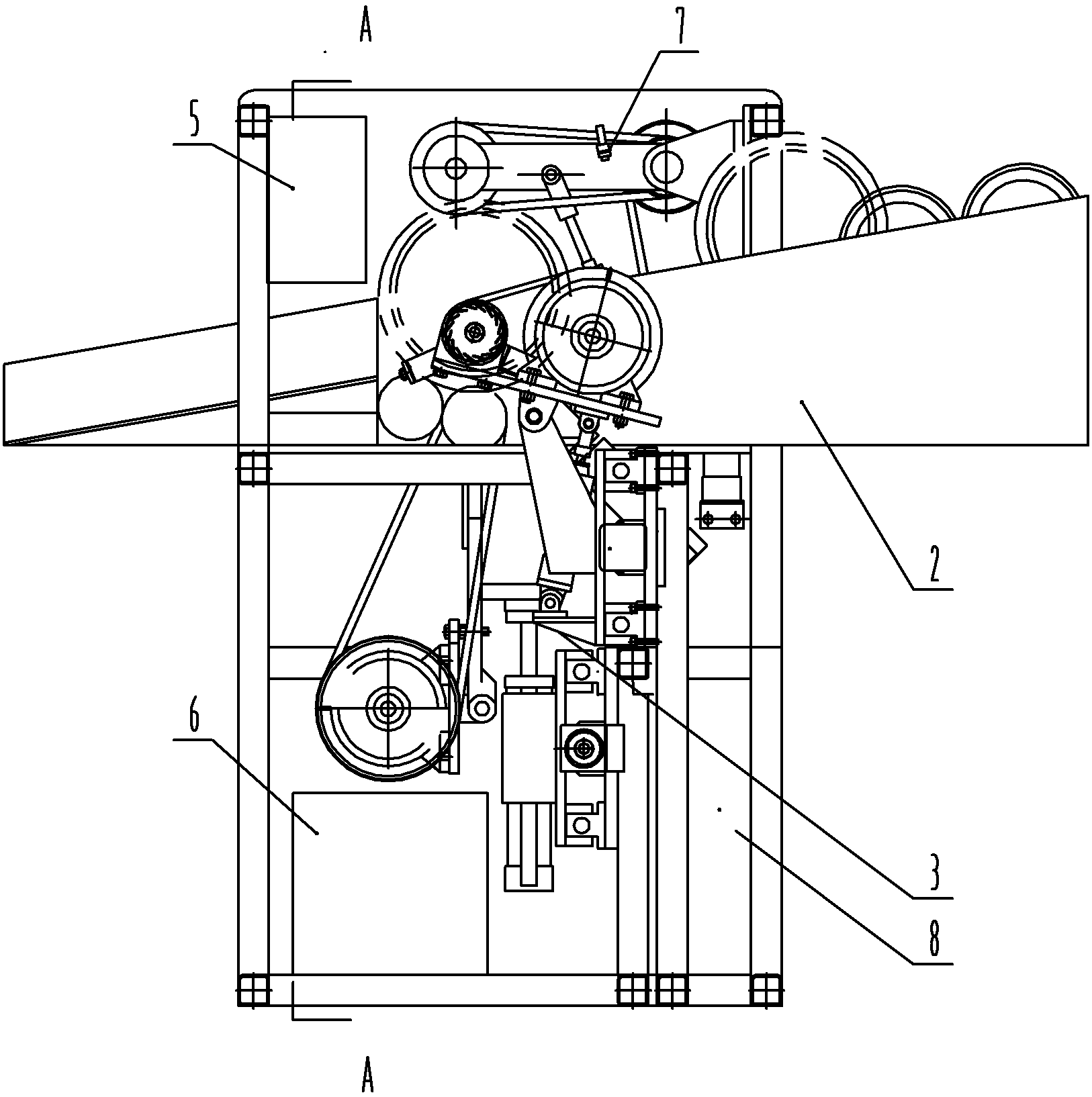

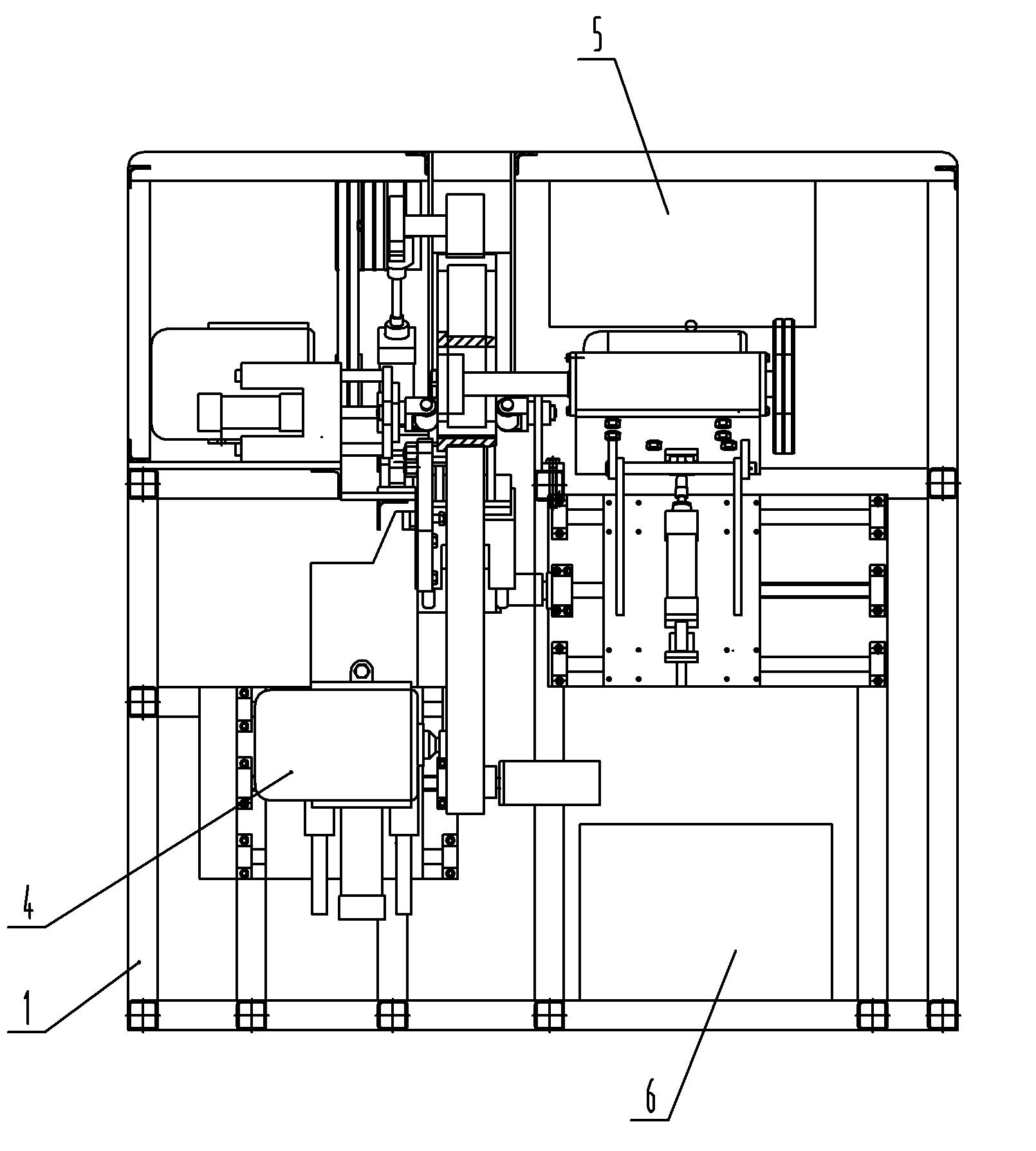

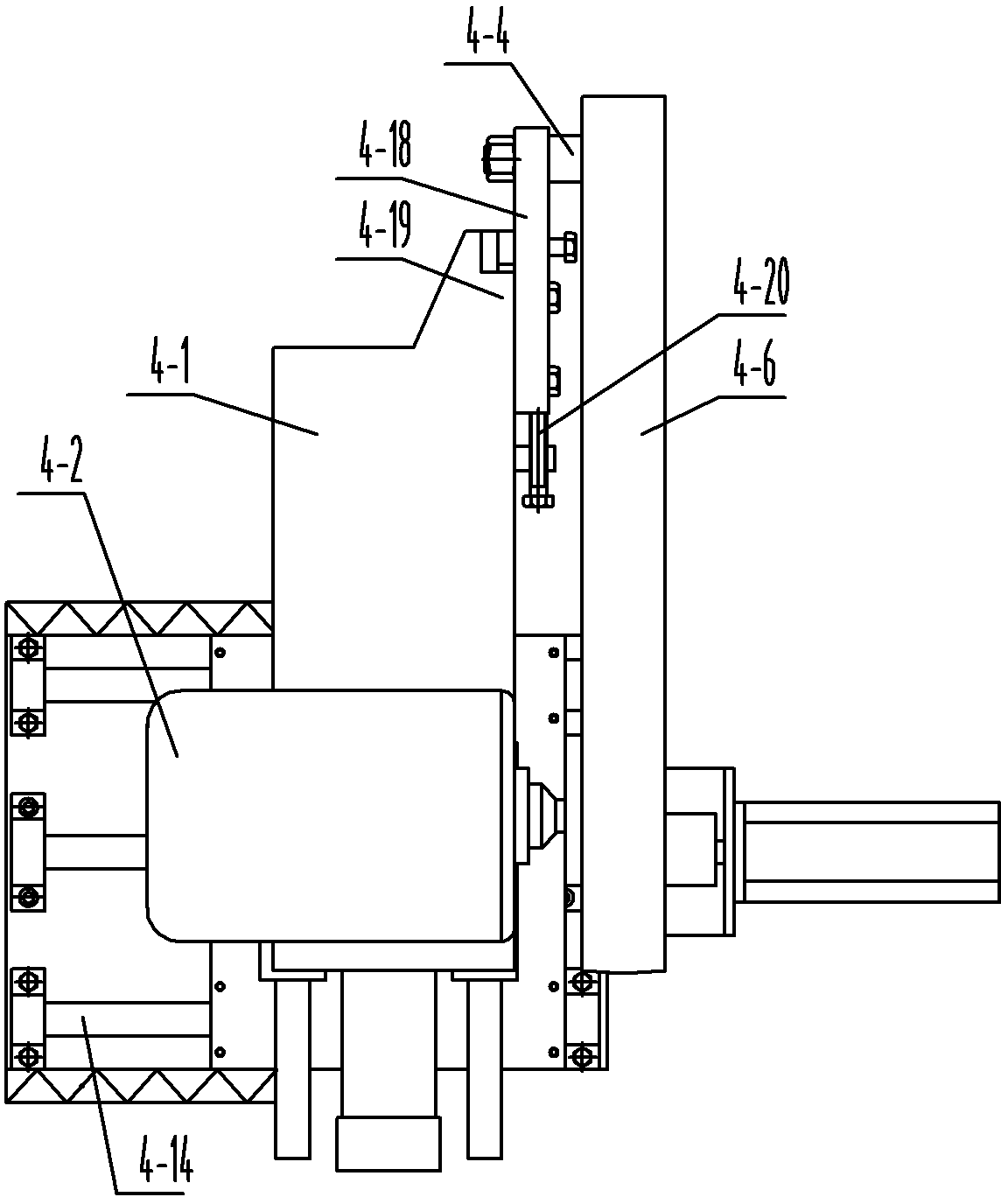

[0037] see figure 1 , figure 2 , in the figure, the present invention handles the inner and outer circle full-automatic polishing machine of the inner and outer rings of passenger car bearings, including a machine body 1, and the two sides of the upper part of the machine body are correspondingly provided with an automatic feeding and discharging mechanism 2, and the side and bottom of the joint of the automatic feeding and discharging mechanism There are inner and outer circular polishing heads and control mechanisms 3 and 4 respectively. Position sensors 7 are installed on the upper part of the machine body and below the automatic feeding and discharging mechanism to detect whether the workpiece is rotating. Automatic workpiece identification mechanisms are installed on both sides of the automatic feeding mechanism. The upper part of the side of the body is fixed with a touch screen and an electrical box 5 and an electrical control box 6 at the lower part of the inner poli...

Embodiment 2

[0044] Present embodiment figure is not drawn. This embodiment is structurally similar to Embodiment 1, and the same structural parts will not be repeated here. The difference is that the pressing part and the driving part contained in the workpiece pressing and driving mechanism described in this embodiment are split structures. The pressing part is located above the workpiece, and the driving part is located below the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com