Full-automatic novel anti-seismic brickwork forming machine and achieving method thereof

A realization method and fully automatic technology, applied in the direction of ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems such as the inability to produce new anti-seismic masonry bricks, achieve automation, high production efficiency, quality assurance, and high The effect of creativity and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

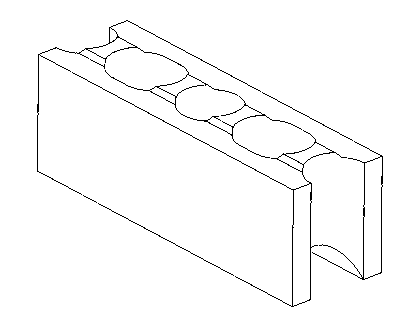

[0044] Such as figure 1 As shown, the new anti-seismic masonry brick combines the advantages of wall bricks and cast-in-place in the prior art, and is constructed through the new anti-seismic masonry brick, and then the foundation, walls, beams, floors, and roofs are connected by reinforced concrete pouring. As a whole, its safety and reliability are greatly improved, and it can resist strong earthquakes. The raw materials of the new anti-seismic masonry bricks are mainly sand, cement, fly ash, and slag, and at the same time, industrial waste, construction waste, crop straw and other waste materials in the traditional sense are added to realize the reuse of waste materials. Masonry bricks are naturally air-dried, energy-saving and environmentally friendly. In the prior art, brick making machines or brick body forming machines are mostly suitable for the manufacture of brick bodies currently on the market, but for the above-mentioned new type of anti-seismic masonry bricks, ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com