Device and method for determining high temperature and high pressure full diameter core mud pollution evaluation

A full-diameter core, high-temperature and high-pressure technology, used in surveying, earth-moving drilling, wellbore/well components, etc., can solve the problems of low fluid volume, small experimental core size, experimental test accuracy and representative limitations, etc., to eliminate Easy to block and easy to damage, good circulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

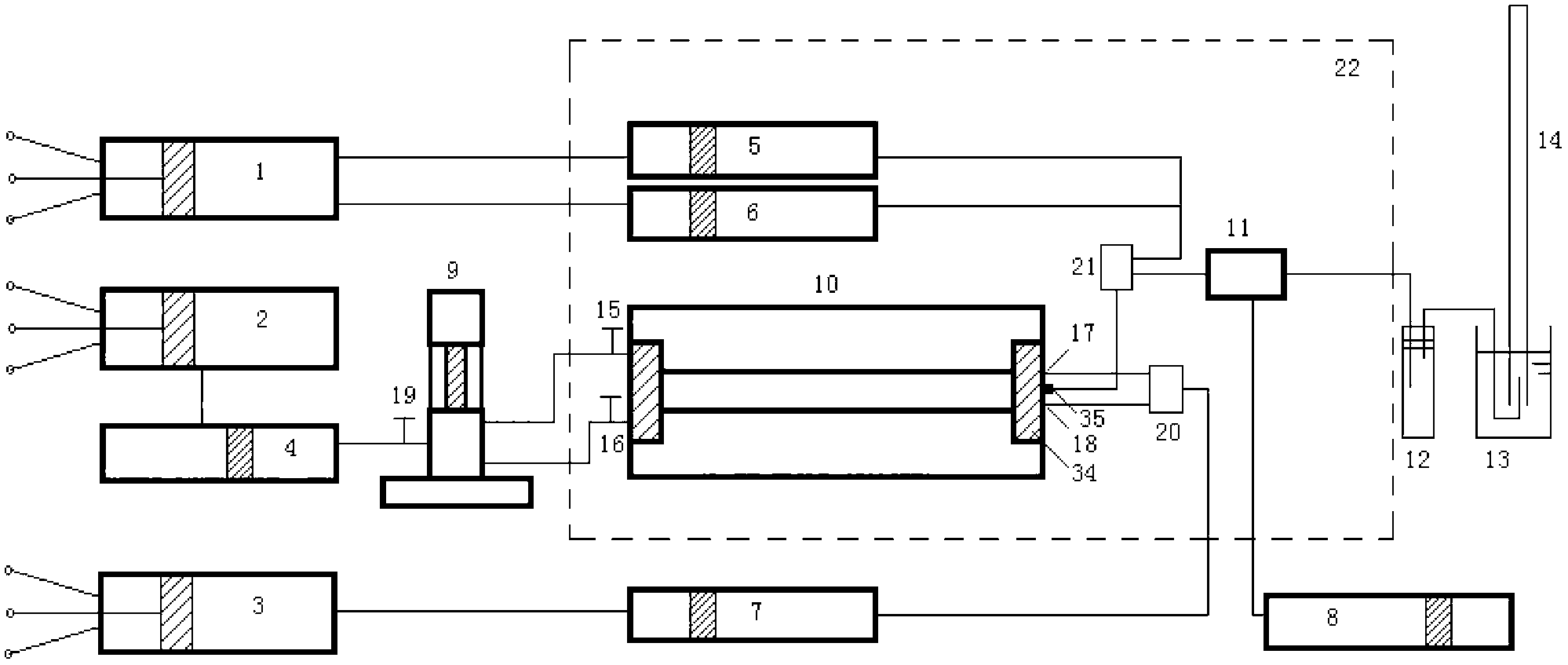

[0027] Further illustrate the present invention below in conjunction with accompanying drawing.

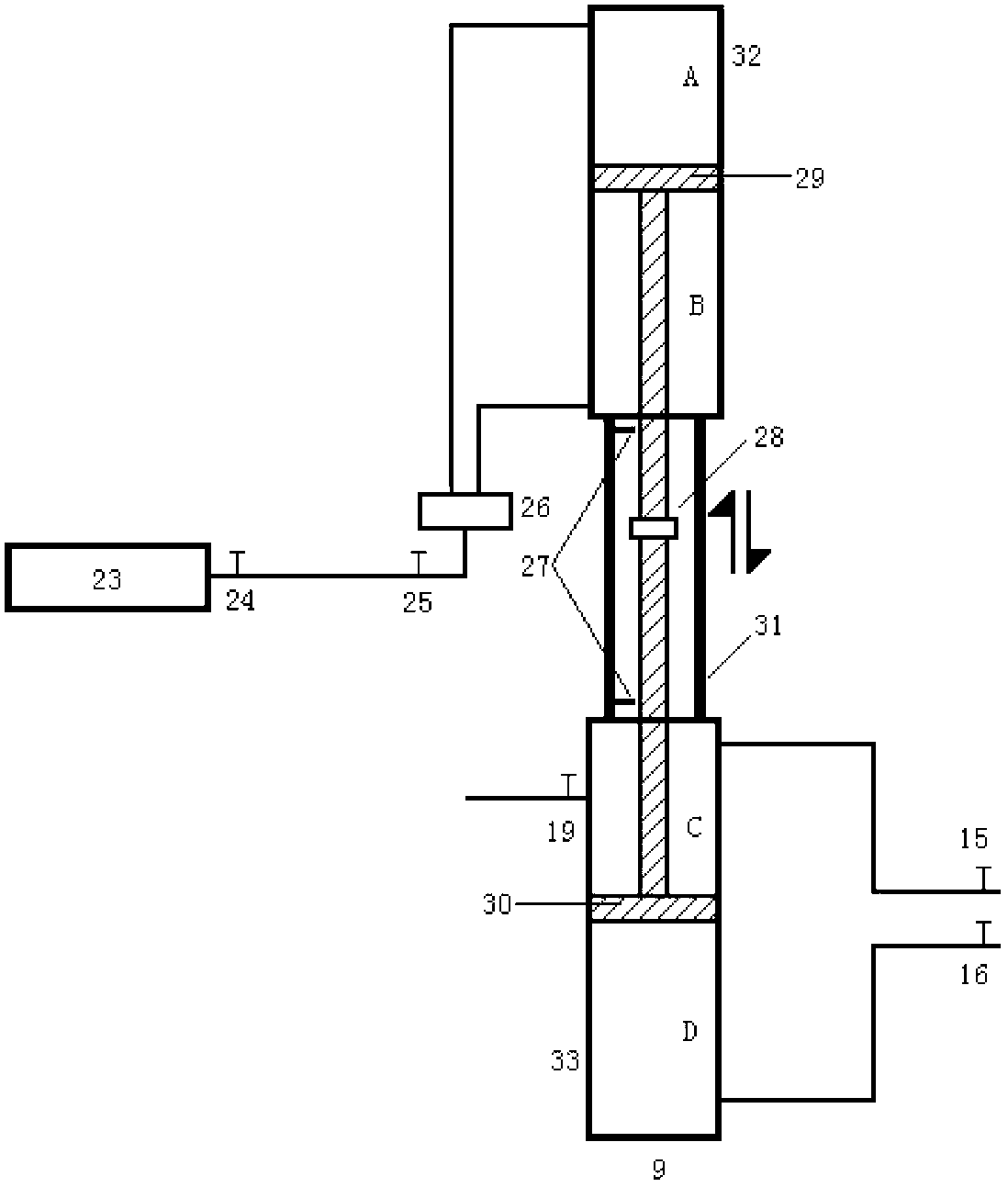

[0028] see figure 1 . High temperature and high pressure full-diameter core mud pollution evaluation device, mainly composed of injection pump 1, injection pump 2, confining pressure pump 3, mud intermediate container 4, mud circulation device 9, full-diameter core holder 10, nitrogen intermediate container 5. Formation water intermediate container 6, confining pressure intermediate container 7, back pressure intermediate container 8, and scale tube. The full-diameter core holder, nitrogen intermediate container, and formation water intermediate container are located in a high-temperature, high-pressure, constant-temperature oven 22. There is a full-diameter rock core in the full-diameter core holder, and the outlet end has a core-holding probe 34, an injection hole 35 and two pressure holes, and the two pressure holes are the axial pressure hole 17 and the confining pressure hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com